Warner Electric ER-1225 User Manual

Page 14

14 Warner Electric • 800-825-9050

819-0466

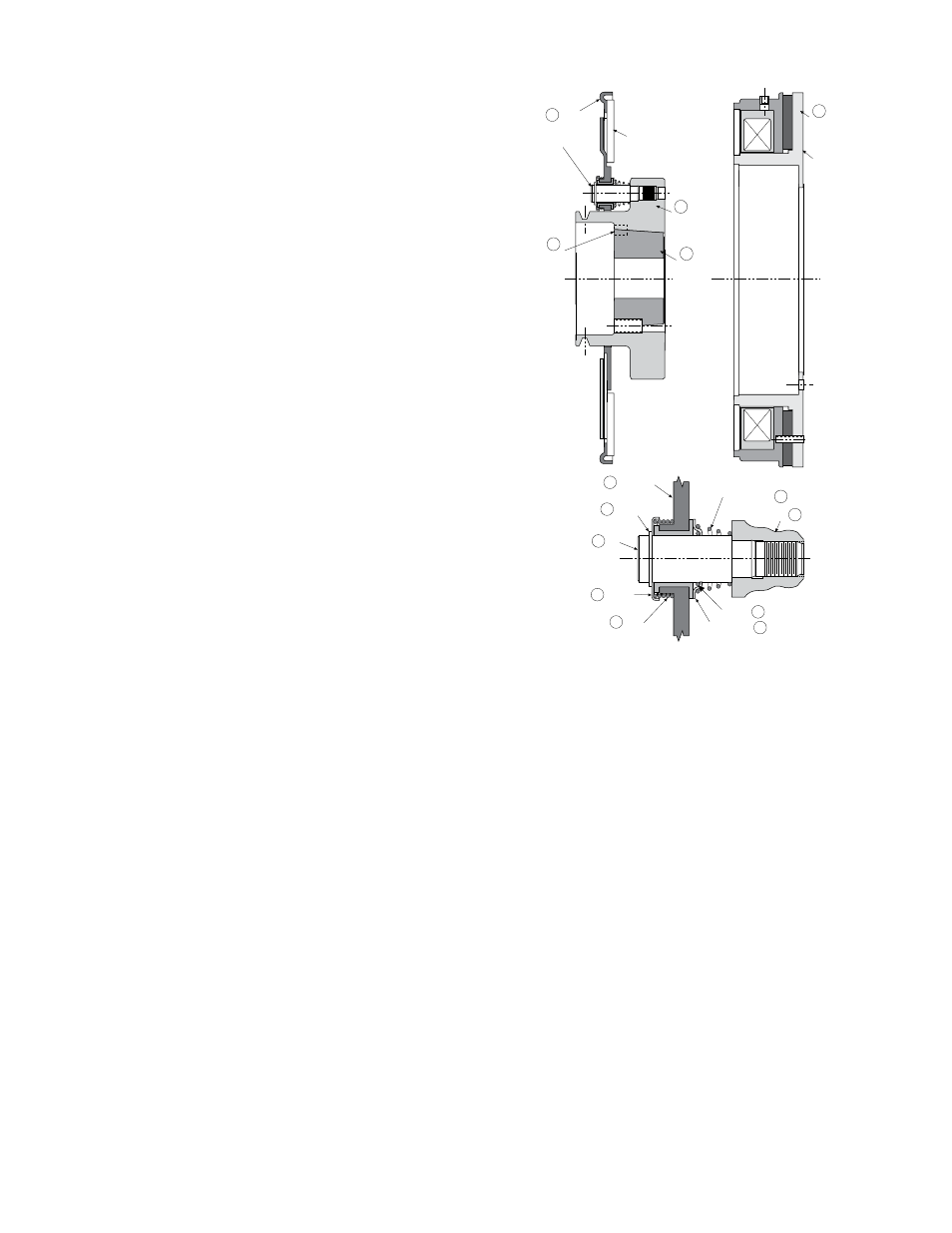

INSTALLATION FOR ER-1225

BRAKE WITH INSIDE

ARMATURE HUB

Technical Information:

Static Torque: . . . . . . . . . . . . . . . . . . . . 400 lb .ft .

Max RPM: . . . . . . . . . . . . . . . . . . . . . . . . . 3600

Voltage: . . . . . . . . . . . . . . . . . . . . . . 45-70 VDC

Total weight: . . . . . . . . . . . . . . . . . . . . . . . . 60 lb .

Current draw: . . . . . . . . . . 0 .256 amp @ 60 volts

Resistance at 20 degrees C .235 ohms ± 10%

Step 1: Remove the ER brake from its shipping

carton . The carton contains the magnet

(Item 11) and armature (Item 3) plus

mounting hardware and conduit box .

(See Figure 18) Inspect the components

to make sure they have not been

damaged in shipping .

Step 2: Wipe the magnet and its mounting

surface clean and remove any burrs .

(Careful - No solvent on friction

face!)

Step 3: Assemble the conduit box to the magnet

per instructions included with the conduit

box .

Step 4: Position the aluminum adapter on the

motor pilot . Align holes in the adapter

with holes in the motor . Following the

manufacturer’s instructions, apply

grade 242 loctite to the threads of each

furnished cap screw, add a lockwasher,

and fasten the adapter on the motor .

Tighten these screws 25 to 28 lb .ft .

torque with a torque wrench .

(The adapter must be machined to pilot on

the motor and magnet pilot mounts, and

align within the tolerences specified in the

introduction to this manual.)

Magnet

11

Mounting

Surface

Taperlock

Bushing

See Detail A

Hub

Armature

3

2

Set Scre

12

1

o rking

Surface

Detail A

ollo

p up

e

Spring

etainer

ing

in

Armature

ello Spring

Hub

Detent

Detent up

1

3

2

Figure 18 - Assembled brake showing item

numbered components. Item numbers shown

will be referenced throughout this installation

procedure.

Step 5 . Position the magnet on the adapter pilot

and align the holes in the magnet with

the adapter holes . Following the

manufacturer’s instructions, apply grade

242 Loctite to the threads of each

furnished cap screw, add a lock washer,

and fasten the magnet on the adapter .

Tighten these screws to 25 to 28 lb .ft .

torque with a torque wrench .

Make electrical connection . The positive and

negative of the power lead must be connected to

the positie and negative lead wires or terminals

of the brake, respectively . Follow KONE Inc .

instructions to set the release voltage of the brake .