Warner Electric ER-1225 User Manual

Page 16

16 Warner Electric • 800-825-9050

819-0466

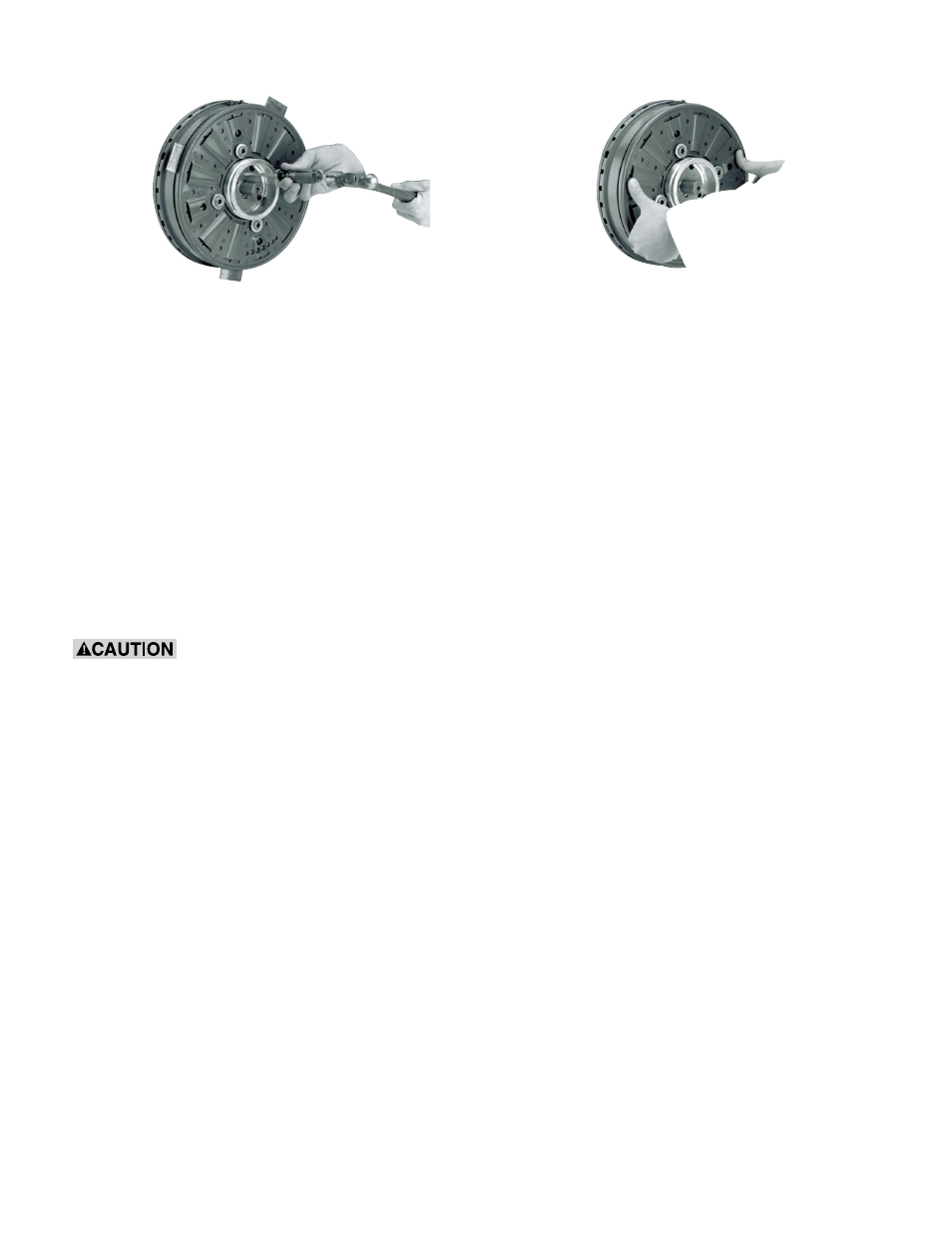

Figure 21 - Seating the taperlock bushing.

Step 11: Apply power (60 VDC) to release the

brake . Remove the taperlock bushing

and armature assembly (Items 1,2,3)

from the motor shaft . With a hex key

wrench, remove both set screws (Item

12) from the taperlock bushing (Item 1) .

Insert one set screw into the previously

vacant hole in the taperlock bushing

and tighten this screw until the bushing

is loosened in the hub (Item 2) . If the

bushing does not loosen, tap on the hub

with a plastic hammer .

Do not pry the armature

away from the magnet. This can distort

the armature and require complete brake

replacement.

Step 12: Repeat Steps 6 ,7, 8, 9, and 10 .

Step 13: Make the electrical connections if they

have not been made . Apply power

(60 VDC) to the brake and remove the

shims . Set the airgap by pressing the

armature into contact with the magnet

and then releasing as shown in Figure

22 . The armature should spring back

approximately 3/64 ( .045) inches .

Figure 22 - Setting the airgap.

Step 14: If the brake includes temperature and

wear sensor wires, follow KONE Inc .

instructions to make proper connections .

Color coding is as follows:

Yellow wire(s) - temperature sensor

Red wire - 90% wear sensor

Black wire - 70% wear sensor

Step 15: Burnish the brake as follows: Start and

stop the escalator 30 times . Allow 5-10

seconds delay between each start and

stop .

Step 16: With power off, check brake static

torque, which must be at least 400 lb .ft .

excluding system drag . If less, repeat

Step 15 . If the brake does not meet the

torque requirement after two burnishings,

replace it .

Step 17: When the armature is released and

rotating freely, the armature working face

should not rub on the magnet working

face and the armature working face axial

runout (wobble) should not exceed .015

inch . If the armature rubs or wobbles

excessively, remove the armature

assembly and reassemble it as instructed

above . If the problem persists, replace

the brake .

Step 18: Brake installation is complete . Follow

KONE Inc . instructions to install the

remainder of the system .