Warner Electric ER-1225 User Manual

Page 17

Warner Electric • 800-825-9050

819-0466 17

MAINTENANCE INSTRUCTIONS: All

Brakes

Once an electrically released brake is properly

installed, periodic checks of the brake for

worn out conditions are required. Experience

will determine the proper inspection interval .

Furthermore, in order to refresh the mating

surfaces, it is recommended that burnishing

as described in the installation procedure be

performed once a month .

Check for worn out conditions as follows:

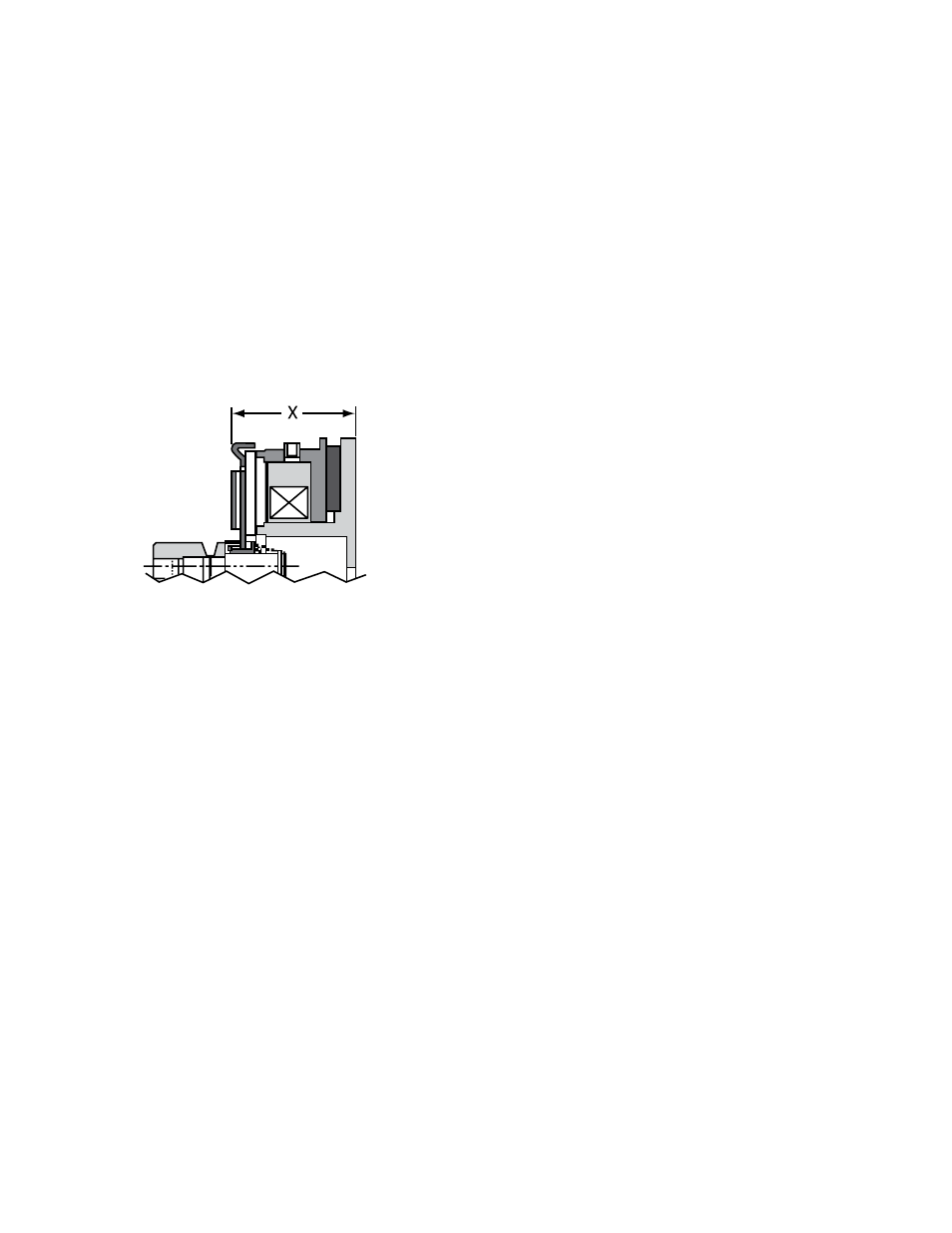

Figure 23 - Measure dimension “X’’ to

determine worn out condition.

Turn off power to the brake . The armature must

contact magnet all around the circumference

and there should be no airgap between armature

& magnet . If there is partial or no engagement,

replace the brake . Check the combined thickness

of the armature and magnet as shown in Figure

23 - “dimension X” . If this dimension is less than

or equal to 2 .420” (2-27/64”) for size ER-825 or

2 .875” (2 -7/8”) for size ER-1225, then the brake

is worn out and should be replaced immediately .

Discard all the brake components and do not use

any of them with the new brake .

After completing an inspection with the machine

turned off, perform the normal burnish procedure

used during installation of a new brake . Check the

static torque of the brake . If the torque is below

the rated level, perform the burnish procedure

again and check for rated torque . If torque falls

below the rated level, replace the brake .

Check the air gap: When the armature is rotating

freely in a released mode, the armature working

face should not rub on the magnet working face .

Armature working face axial runout (wobble)

should not exceed .015 inch . If any of the above

conditions are present, remove the armature

assembly from the motor brake and reassemble

it on the motor as explained in the installation

procedure . If problem persists, replace the brake .

Wear pattern: Wear grooves will appear on the

friction surfaces . This is a normal wear condition,

and does not impair the performance of the unit .

Never machine the friction surfaces to remove

grooves or score marks resulting from normal

wear .