Warner Electric ER-1225 User Manual

Page 8

8 Warner Electric • 800-825-9050

819-0466

Step 18: Brake installation is complete . Follow

KONE Inc . instructions to install the

remainder of the system .

INSTALLATION FOR ER-825 BRAKE

WITH INSIDE ARMATURE HUB

AND TAPER-LOCK BUSHING:

Technical Information:

Static Torque: . . . . . . . . . . . . . . . . . . . . 125 lb .ft .

Max RPM: . . . . . . . . . . . . . . . . . . . . . . . . . 3600

Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . 90 VDC

Total Weight: . . . . . . . . . . . . . . . . . . . . . 15 .6 lb .

Current Draw: . . . . . . . . . . 0 .295 amp @ 90 Volts

Resistance at 20 degrees C: .305 Ohms ± 10 %

Step 1: Remove the ER brake from its shipping

carton . The carton contains a magnet

(Item 10) and armature (Item 3), plus

mounting hardware and a conduit box .

(See Figure 7) Inspect the components

to make sure they have not been

damaged in shipping

Step 2: Wipe the magnet and its mounting

surface clean and remove any burrs .

No solvent on friction face!

Step 3: Assemble the conduit box to the magnet

in accordance with the instructions

included with the conduit box .

Step 4: Insert an aluminum (or other non-

magnetic material) spacer into the

magnet bore and align the holes in both

components .

(This spacer must be machined to pilot on

the motor and magnet pilot mounts and

align within the tolerances specified in the

introduction to this manual.) (See Figure 8)

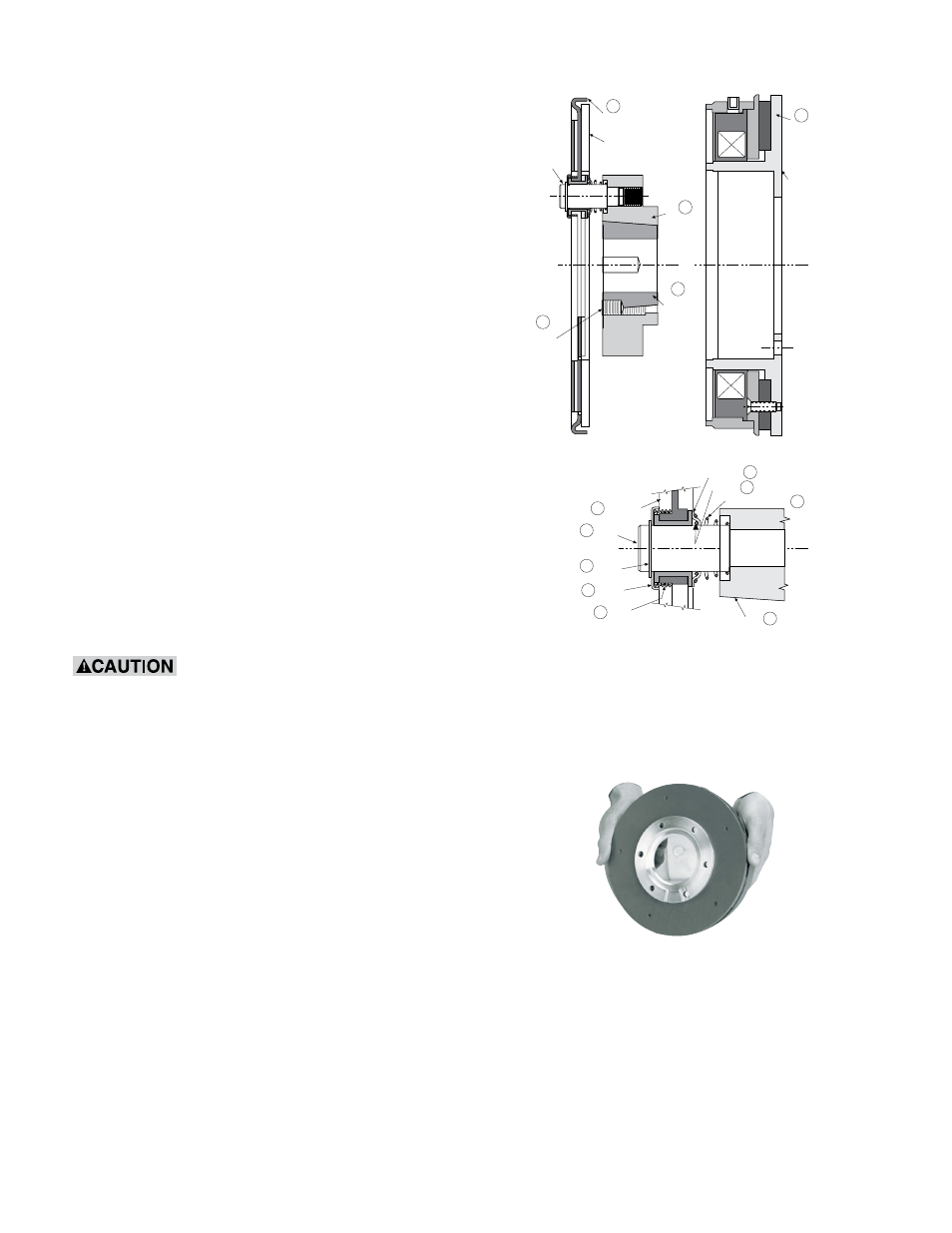

Detail A

Follow

Up Cup

Retainer

Ring

Drive Pin

Armature

Auto Gap Spring

Detent

Detent Cup

10

9

4

3

5

6

7

Hub 1

Red

Spring

8

Magnet

10

See

Detail A

Armature

Set

Screw

Taperlock

Bushing

3

12

Hub 2

1

Working

Surface

Mounting

Surface

Figure 7 - Assembled brake showing

numbered components. Item numbers shown

will be referenced throughout this installation

procedure.

Figure 8 - Aluminum Spacer installed