Warner Electric SFC-1525 User Manual

Page 6

6

Warner Electric • 800-825-9050

P-207

•

819-0516

Maintenance

Wear Pattern: Wear grooves appear on the armature

and rotor surfaces. This is a normal wear condition, and

does not impair functioning of the unit. Normally, the

rotor and armature, as a mating pair, will wear at the

same rate. It is the usual recommendation that both

components be replaced at the same time.

Remachining the face of a worn armature is not

rec om mend ed. If a replacement armature is to be used

with a used rotor, it is necessary to remachine the worn

rotorface. In refacing a rotor: (1) machine only enough

material to clean up the complete face of the magnet; (2)

hold the face within .005'' of parallel with the mounting

plate; and (3) undercut the molded facing material

.002''-.004'' below the metal poles.

Heat: Excessive heat and high operating temperatures

are causes of rapid wear. Units therefore, should be

ven ti lat ed as efficiently as possible, especially if the

ap pli ca tion requires fast, repetitive cycle operation.

Foreign Materials: If units are used on machinery

where fine, abrasive dust, chips or grit are dispelled into

the at mo sphere, shielding of the brake or clutch may be

nec es sary if maximum life is to be obtained.

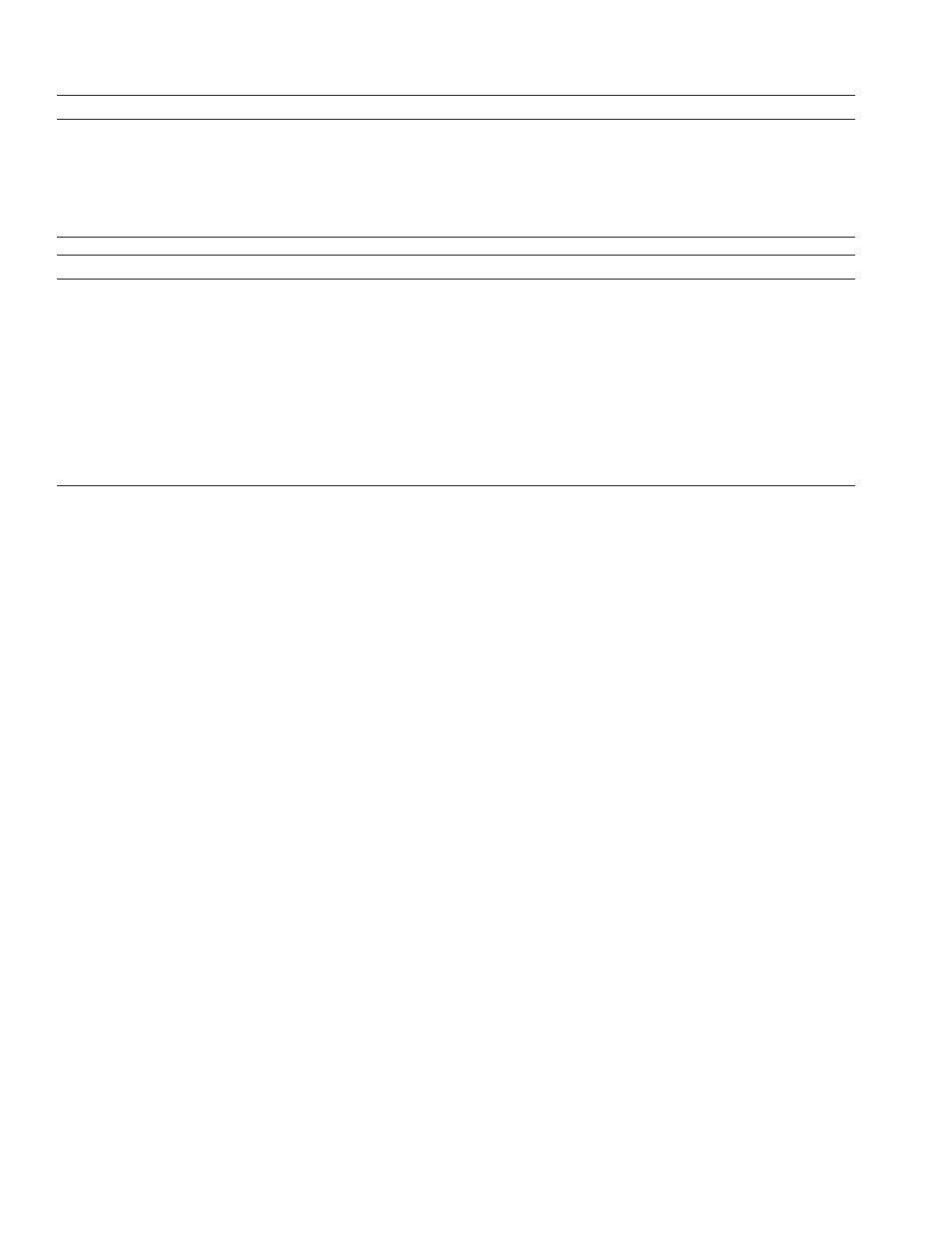

Electrical Coil Data

Unit Size

SF-825

SF-825 Brg.

SF-1000

Voltage–DC

6

24

90

6

24

90

6

24

90

Resistance @ 20°C–Ohms

1.23

20.9 267.0

1.098

14.6

221

1.07

14.4 214.4

Current–Amperes

4.9

1.15

.34

5.464

1.65

.407

5.61

1.67

.42

Watts

29

28

30

33

40

37

34

40

38

Coil Build-Up–Milliseconds

222

200

245

180

200

225

256

275

283

Coil decay–Milliseconds

105

120

100

115

120

130

123

105

90

Unit Size

SF-1225

SF-1525 SF-1525 HT

Voltage – DC

6

24

90

6

24

90

6

24

90

Resistance @ 20°C–Ohms

1.21

19.5 268.3

1.11

15.5

239.1

.55

7.63 113.4

Current – Amperes

4.97

1.23

.34

5.41

1.55

.38

10.83

3.14

.794

Watts

30

30

30

32

37

34

65

75

72

Coil Build-Up – Milliseconds

475

440

510

505

535

575

480

535

560

Coil decay–Milliseconds

240

230

220

230

237

215

210

183

160

Notes: Build-up time equals current to approx.* 90% of steady state value and flux to 90%

Decay time equals current to approx.* 10% of steady state value and flux to 10%.

*Approx. because current leads or lags flux by a small amount.

Burnishing and Maintenance

Burnishing

Intimate metal to metal contact is essential between the

armature and the metal rings (poles) of the magnet or

rotor. Warner Electric clutches and brakes leave the

fac to ry with the friction material slightly undercut to

assure good initial contact.

Normally, the desired wearing-in process occurs nat u ral ly

as the surfaces slip upon engagement. The time for

wear-in, which is necessary to obtain the ultimate torque

of the unit, will vary depending on speed, load, or cycle

duty.

If maximum torque is required immediately after

in stal la tion, the unit should be burnished by slipping

the friction surfaces together at reduced voltage. It is

rec om mend ed that the burnishing be done right on

the application, if at all possible.

Burnishing at high speed will result in a smoother wear-in

pattern and reduce the time for burnishing. The volt age

should be set at approximately 30% or 40% of the rated

value.

The unit should be cycled on and off to allow sufficient

time between slip cycles to prevent overheating.

When a Warner Electric brake or clutch is properly

as sem bled and installed, no further servicing, lubrication,

or maintenance should be required throughout the life of

the unit.