0 - 20 ma dc, Table 15 – analog input 2 electrical ratings – KB Electronics KBDA-42 User Manual

Page 51

50

TABLE 14 – ANALOG INPUT 1 ELECTRICAL RATINGS

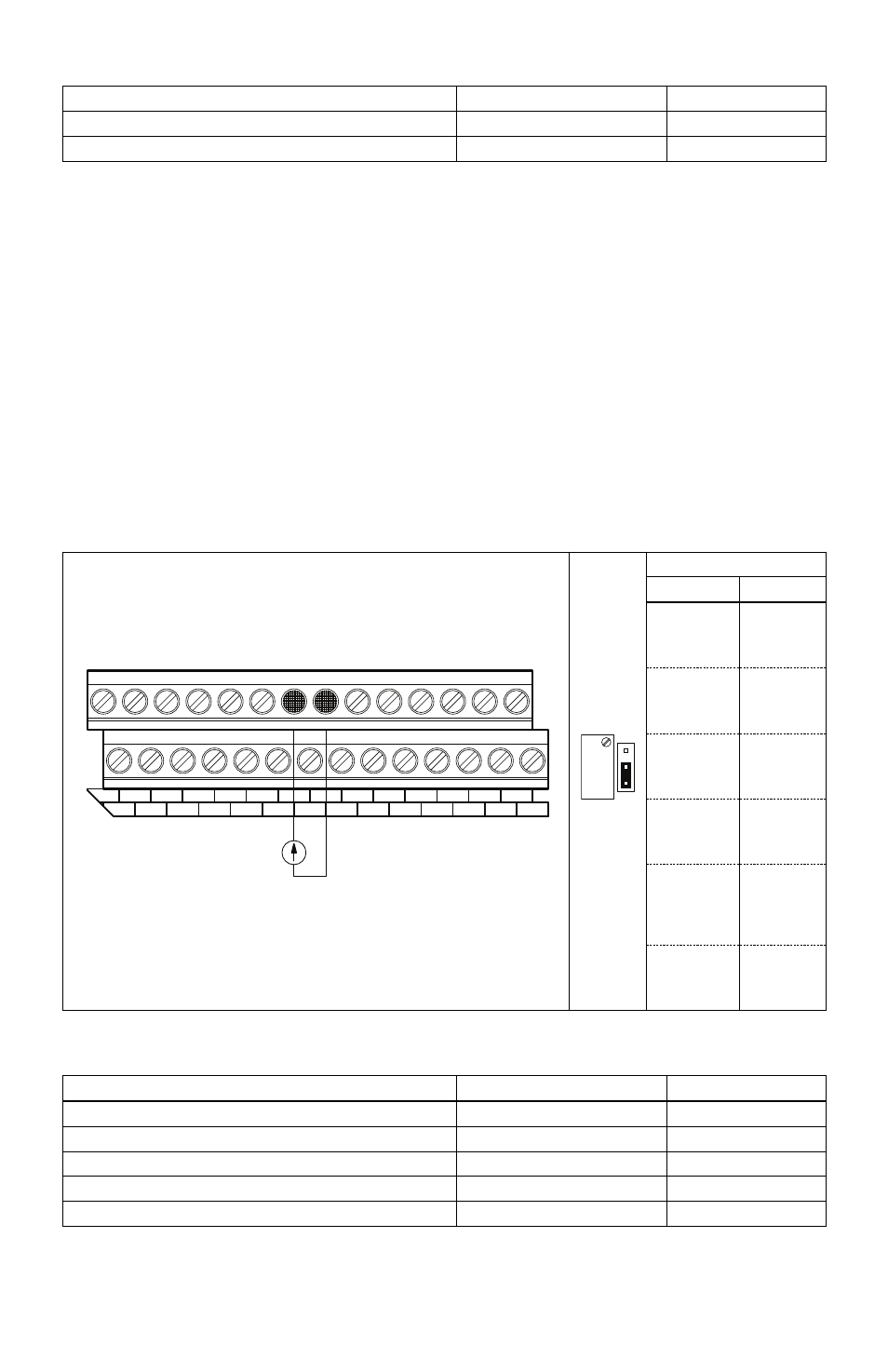

FIGURE 35 – ANALOG INPUT 2 SIGNAL CURRENT FOLLOWING CONNECTION AND FUNCTION SETTINGS

14

4

3

2

1

16

TB1

15

17

18

13

12

11

10

8

7

6

5

9

21

19

20

22

23

26

24

25

27

28

0 - 20 mA DC

-

+

VOLT

CUR

MAX2

J1

Function Settings

Function No.

Range/Code

2.00

Frequency

Control

0003

Analog

Signal 2

9.05

Analog

Input 2 Gain

0 – 500

Set to the

Desired Gain

9.06

Analog

Input 2 Slope

0000 or 0001

Positive or

Negative

9.07

Analog

Input 2 Offset

0 – 100

Set to the

Desired Offset

9.08

Analog

Input 2 Type

0000

Analog

Voltage or

Current

9.09

Analog Input 2

Response Time

2 – 100

Set to the

Desired Time

Parameter

Specification

Factory setting

Voltage Range (Volts DC)

0 – ±5

0 – 5

MAX1 Scaling Trimpot Range (Volts DC)

0 – 24

5

TABLE 15 – ANALOG INPUT 2 ELECTRICAL RATINGS

Parameter

Specification

Factory setting

Voltage Range (Volts DC)

0 – 5

0 – 5

MAX2 Scaling Trimpot Range (Volts DC)

0 – 24

5

Current Range (mA DC)

0 – 20*

—

Input Impedance for Current Mode (

Ω)

270

—

PWM (kHz, Duty Cycle)

0.15 – 1, 0 – 100

—

* If using 4 – 20 mA DC signal input, the offset setting in Function No. 9.07 must be increased from “0%” (factory setting) to “20%”. Set

Jumper J1 to the “CUR” position.

Analog Input 2 – Connect the signal input to Terminal “21” and the common to Terminal “22”, as

shown in Figure 35. See settings for Analog Input 2 (Function Nos. 9.05 – 9.09). Set Frequency

Control (Function No. 2.00) to Analog Input 2 (“0003”). For voltage input, set Jumper J1 to the “VOLT”

position and set Analog Input 2 Type (Function No. 9.08) to Analog Voltage or Current ((“0000”) (facto-

ry setting)). For current input, set Jumper J1 to the “CUR” position and set Analog Input 2 Type

(Function No. 9.08) to Analog Volgage or Current ((“0000”) (factory setting)). For PWM input set

Jumper J1 to the “VOLT” position and set Analog Input 2 Type (Function No. 9.08) to PWM (“0001”).

See Table 15 for Analog Input 2 electrical ratings.

If the Analog Input 2 signal is higher than the input signals specified in Table 15, use Trimpot MAX2 to

attenuate it. Apply the maximum signal input and set the drive for full speed output and observe the

display. Rotate Trimpot MAX2 counterclockwise until the drive output frequency begins to drop. Then

rotate Trimpot MAX2 clockwise until the display returns to the maximum output frequency.