KB Electronics KBDA-42 User Manual

Page 10

9

Description

Accessory Part No.

Model

KBDA-24D

Model

KBDA-27D

Model

KBDA-29

Model

KBDA-45

Model

KBDA-48

On/Off AC Line Switch – Disconnects the AC line. Mounts on the enclosure

cover and is supplied with a switch seal to maintain liquidtight integrity.

9482

9523

9532

9532

9532

AC Line Filter1 – Provides Class A Industrial Standard RFI (EMI)

suppression. Installs onto the drive’s PC board with quick-connect

terminals.

Suffix “S” – Filter must be used with built-in On/Off AC Line Switch.

Suffix “NS” – Filter must be used without On/Off AC Line Switch.

Suffix

“S”

9507

9512

9479

9479

9479

Suffix

“NS”

9507

9512

9515

9515

9515

IODA Input/Output Multi-Function Board – Provides a variety of functions,

which include preset frequency, up/down frequency control, signal isolation,

isolated output voltage for controlling auxiliary devices, open collector outputs,

and output relay contacts. Mounts on the drive’s PC board with two snap-ins

(located on the bottom of the mounting base) and two screws (provided). All of

the IODA inputs and outputs are isolated from the AC line.

See Appendix A, on page 42.

9668

9668

9668

9668

9668

Programming Kit – Includes DownLoad Module™ (DLM) handheld program-

ming device, which uploads and downloads drive programs, PC to DLM

serial and USB communication cables, DLM to inverter communication cable,

and PC Windows® based Drive-Link™ communication software.

9582

9582

9582

9582

9582

DIAC Modbus Communication Module – Allows direct communication

between drive and Modbus2 protocol.

9517

9517

9517

9517

9517

Liquidtight Fittings – Provide a liquidtight seal for wiring the drive. Kit

includes three 1/2” and one 3/4” liquidtight fittings.

9526

9526

9526

9526

9526

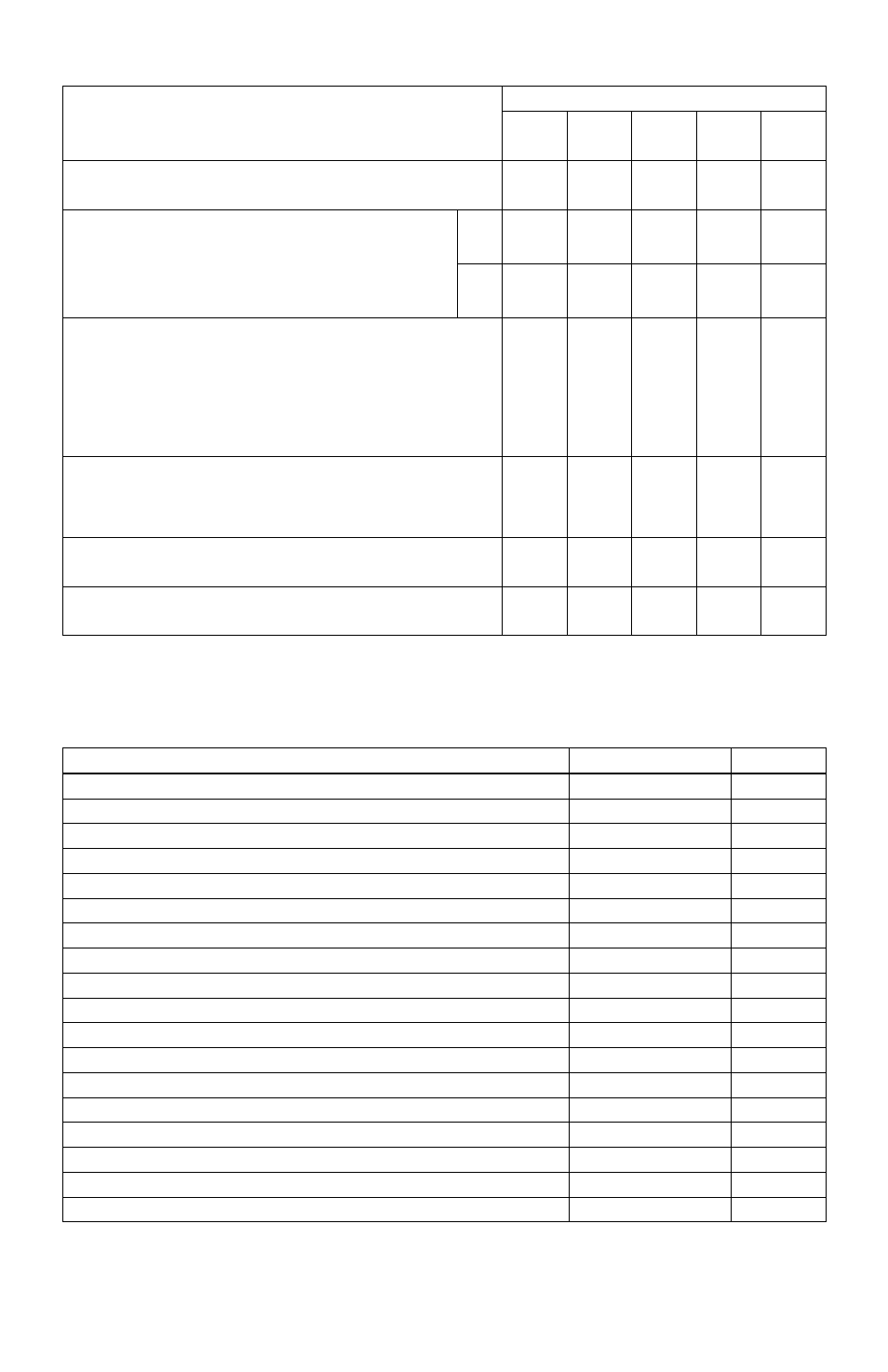

TABLE 1 – OPTIONAL ACCESSORIES

TABLE 2 – GENERAL PERFORMANCE SPECIFICATIONS

Notes: 1. Complies with CE Council Directive 89/336/EEC Industrial Standard. 2. Other protocols available – contact our Sales Department.

Notes: 1. IODA option board required. 2. Dependent on motor performance. 3. Do not operate the drive outside the specified AC line input voltage

operating range.

Description

Specification

Factory Setting

115 Volt AC Line Input Voltage Operating Range (Volts AC)

115 (± 15%)

—

208/230 Volt AC Line Input Voltage Operating Range (Volts AC)

208 (-15%) / 230 (+15%)

—

400/460 Volt AC Line Input Voltage Operating Range (Volts AC)

380 (-15%) – 460 (+15%)

—

Maximum Load (% of Current Overload for 2 Minutes)

150

—

Switching Frequency (kHz)

8, 10, 12

8

Signal Following Input Voltage Range1 (Volts DC)

0 – 5

—

Output Frequency Resolution (Bits, Hz)

10, .06

—

Minimum Operating Frequency at Motor (Hz)

0.3

—

Acceleration Time (Seconds)

0.1 – 180.0

1.5

Deceleration Time (Seconds)

0.3 – 180.0

1.5

Speed Range (Ratio)

60:1

—

Speed Regulation (30:1 Speed Range, 0 – Full Load) (% Base Speed) 2

2.5

—

Overload Protector Trip Time for Stalled Motor (Seconds)

6

—

Undervoltage/Overvoltage Trip Points for 115 Volt AC Line Input (± 5%) (Volts AC)3

76 / 141

—

Undervoltage/Overvoltage Trip Points for 208/230 Volt AC Line Input (± 5%) (Volts AC)3

151 / 282

—

Undervoltage/Overvoltage Trip Points for 400/460 Volt AC Line Input (± 5%) (Volts AC)3

302 / 567

—

Run/Fault Output Relay Contact Rating (Amps at 30 Volts DC, 125 Volts AC, 250 Volts AC)

1, 0.5, 0.25

—

Operating Temperature Range (°C / °F)

0 – 45 / 32 – 113

—