Xyb + base fixed type: double slider type – IAI America IK Series User Manual

Page 13

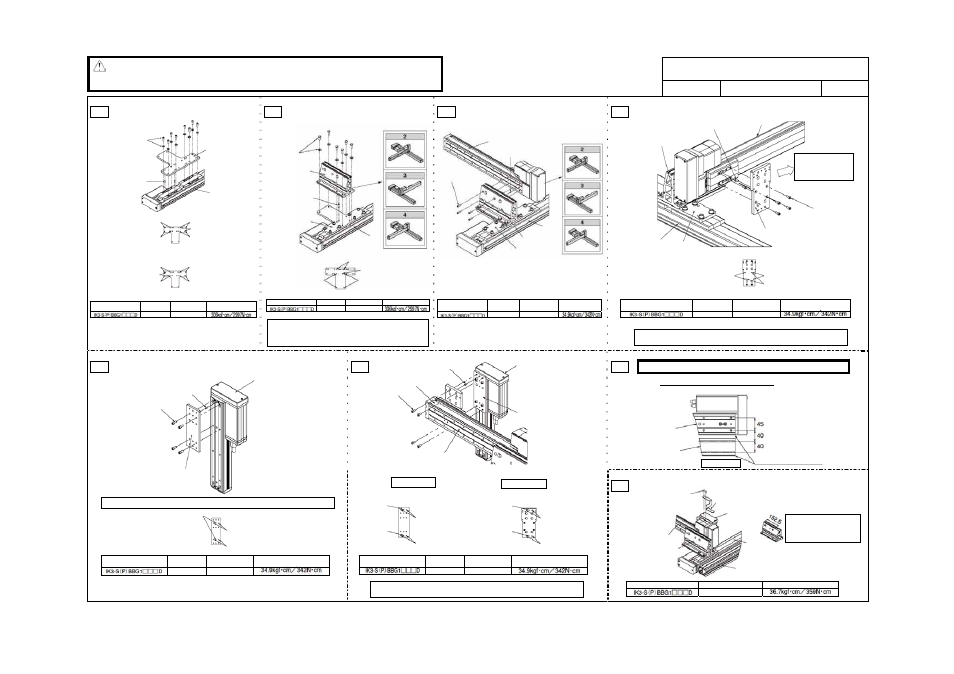

XYB + base fixed type: Double slider type

IK3-S(P)BB

D

DWG. No.

GMM07-059E

1/2

1

2

3

4

7

5

6

8

* This assembly procedure applies to combination direction 1. With other combination directions such as 2 through 4, the actuator and bracket directions are different. If you are using combination direction 2 through 4, assemble

the parts by referring to this drawing.

Model

Parallel pin

Hex

socket-head bolt

Tightening torque

∅8h7 x 18

M8 x 20 mm

Model

Parallel pin

Hex

socket-head bolt

Tightening

torque

∅4h7 x 10

M5 x 15 mm

Model

Parallel pin

Hex head bolt Tightening torque

∅8h7 x 18

M8 x 20 mm

Note:

z Although the corners of each part have been chamfered, exercise due caution during

assembly to prevent injury. If necessary, wear gloves and other protective gears.

z Exercise due caution during assembly to prevent pinching of your hands and fingers.

[Tools] Allen wrench, spanner wrench, ruler

[2] Plate X

Parallel pin (2 pcs)

X-axis

Screw lock holes

Parallel pin holes

Hex socket head

bolt + plain washer

(8 pcs)

Screw lock holes

Screw lock holes

Screw lock holes

Screw lock holes

Screw lock holes

Parallel pin holes

Screw lock holes

Screw lock holes

Combination directions 1, 3

Combination directions 2, 4

Note: To ensure squareness of the X-axis and Y-axis, place one

parallel pin.

After adjusting the squareness of the X-axis and Y-axis,

affix the hex head bolt.

With combination directions

2 through 4, the bracket

direction is different.

Hex head bolt +

high-tension

washer (6 pcs)

[1] XY bracket

[2] Plate X

Parallel pin

(1 pc or 2 pcs)

X-axis

Screw lock holes:

∅9

Parallel pin holes:

∅8

Screw lock holes:

∅9

Screw lock holes:

∅9

With combination directions 2 through

4, the actuator direction is different.

Y-axis

Parallel pin (1 pc or 2 pcs)

X-axis

[2] Plate X

[1] XY bracket

Hex socket-head

bolt (4 pcs)

Model Parallel

pin

Hex socket-head

bolt

Tightening torque

∅5h7 x 14

M5 x 12 mm

Note: To ensure squareness of the X-axis and Y-axis, place one parallel pin.

After adjusting the squareness of the X-axis and Y-axis, affix the hex head bolt.

Parallel pin (1 pc or 2 pcs)

[1] XY bracket

[2] Plate X

X-axis

Screw lock holes:

∅5.5

Parallel pin holes:

∅5

Screw lock holes:

∅5.5

Y-axis

[3] Plate YZ1

Hex socket-head bolt

(4 pcs)

After installing plate

YZ1, move the Y-axis

slider toward the

counter-motor end.

Model Parallel

pin

Hex

socket-head bolt

Tightening torque

∅4h7 x 10

M5 x 12 mm

Parallel pin (1 pc or 2 pcs)

Z-axis

Hex socket-head bolt (4 pcs)

[4] Plate YZ2

Note: On some models, only one parallel pin may be accommodated depending on the axis.

Screw lock holes:

∅5.5

Parallel pin holes:

∅4

Screw lock holes:

∅5.5

Model Parallel

pin

Hex

socket-head bolt

Tightening torque

∅4h7 x 10

M5 x 10 mm

Screw lock holes:

∅5.5

Screw lock holes:

∅5.5

Parallel pin

holes:

∅4

Parallel pin

holes:

∅4

Parallel pin

holes:

∅4

Parallel pin

holes:

∅4

Screw lock holes:

∅5.5

Screw lock holes:

∅5.5

Parallel pin (1 pc or 2 pcs)

Z-axis

[4] Plate YZ2

Y-axis

[3] Plate YZ1

Hex socket-head

bolt (4 pcs)

[4] Plate YZ2

[3] Plate YZ1

Note: To ensure squareness of the Y-axis and Z-axis, place one parallel pin.

After adjusting the squareness of the Y-axis and Z-axis, affix the hex head bolt.

Model

Hex socket-head bolt

Tightening torque

M4 x 8 mm

The following procedures apply to configurations with a cable bearer.

Install the X-axis and guide rail X.

X-axis

[5] Guide rail X

Align the end face of

the base with the end

face of guide rail X.

Bottom view

Y-axis

Hex socket-head bolt (2 pcs)

Hex nut (2 pcs)

[8] Bearer mounting bracket 1

X-axis

[5] Guide rail X

[1] XY bracket

Z-axis

Set the dimension from the

side face of the XY bracket to

the tip of bearer mounting

bracket 1 [8] to 152.5 mm.