Maintenance and inspection, 1 inspection items and schedule, 2 visual inspection of exterior – IAI America RCP3-RA2BR User Manual

Page 46: 3 cleaning

40

13. Maintenance and Inspection

13. Maintenance and Inspection

13.1

Inspection Items and Schedule

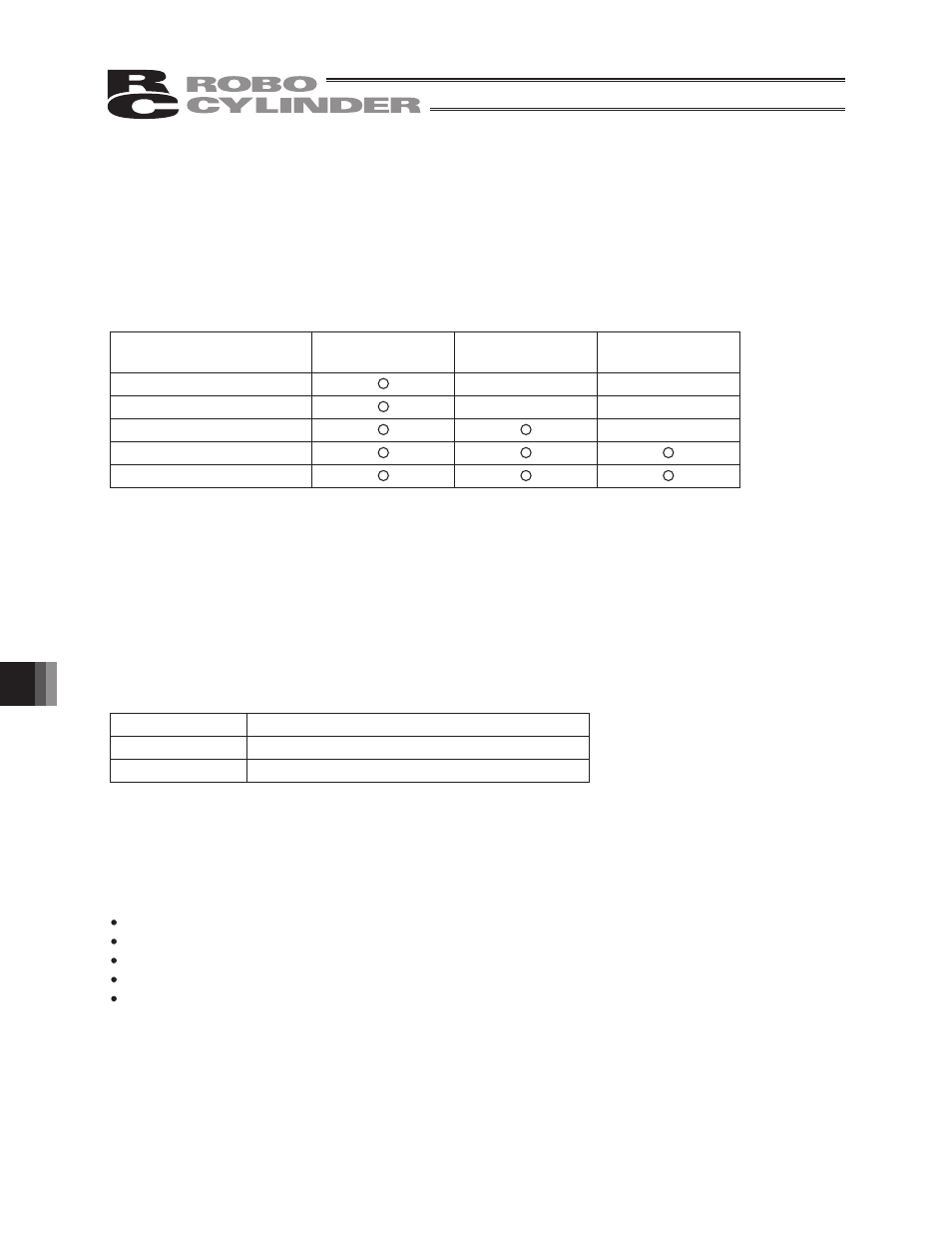

Perform maintenance and inspection at the schedule specified below.

This schedule assumes 8 hours of operation a day.

If the actuator is operated continuously day and night or at a higher utilization rate, shorten the inspection

intervals according to the situation.

n

o

i

t

c

e

p

s

n

i

l

a

u

s

i

V

of exterior

Inspection

of interior

Greasing

Startup inspection

1 month after startup

3 months after startup

6 months after startup

Every 6 months thereafter

13.2

Visual Inspection of Exterior

In the visual inspection of exterior, check the following items.

Actuator

Loose actuator mounting bolts, etc.

Cables

Scratches, connection at connectors

Overall

Abnormal noise, vibration

If the actuator is fixed vertically, grease on the guide may drip depending on the environment. In this case,

clean the dirtied areas and add grease.

13.3 Cleaning

Clean exterior surfaces as necessary.

Use a soft cloth to wipe away dirt and buildup.

Do not blow too hard with compressed air as it may cause dust to get in through the gaps.

Do not use oil-based solvents as they can harm lacquered and painted surfaces.

To remove severe buildup, wipe gently with a soft cloth soaked in a neutral detergent or alcohol.

Continuous back and forth operation within a distance less than 30mm may cause wear of grease.

It is recommended to have 5 rounds of back and forth operation in a distance more than 50mm after every

5,000 to 10,000 rounds of the short distance operation. (Conduct back and forth operation in full stroke

distance for ROBO Cylinder with its stroke less than 50mm.) A layer of the grease will recover.

*1