Installation, 1 installation of actuator – IAI America RCP3-RA2BR User Manual

Page 37

31

9. Installation

9. Installation

The actuator mounting surface should be machined or otherwise processed to a smooth surface of

equivalent precision.

9.1

Installation of Actuator

This actuator contains installation tap holes which allow it to be secured from the rear.

(Note that tap hole size depends on model. Please see 2, "External Dimensions."

The actuator also contains reamed holes for use with positioning pins.

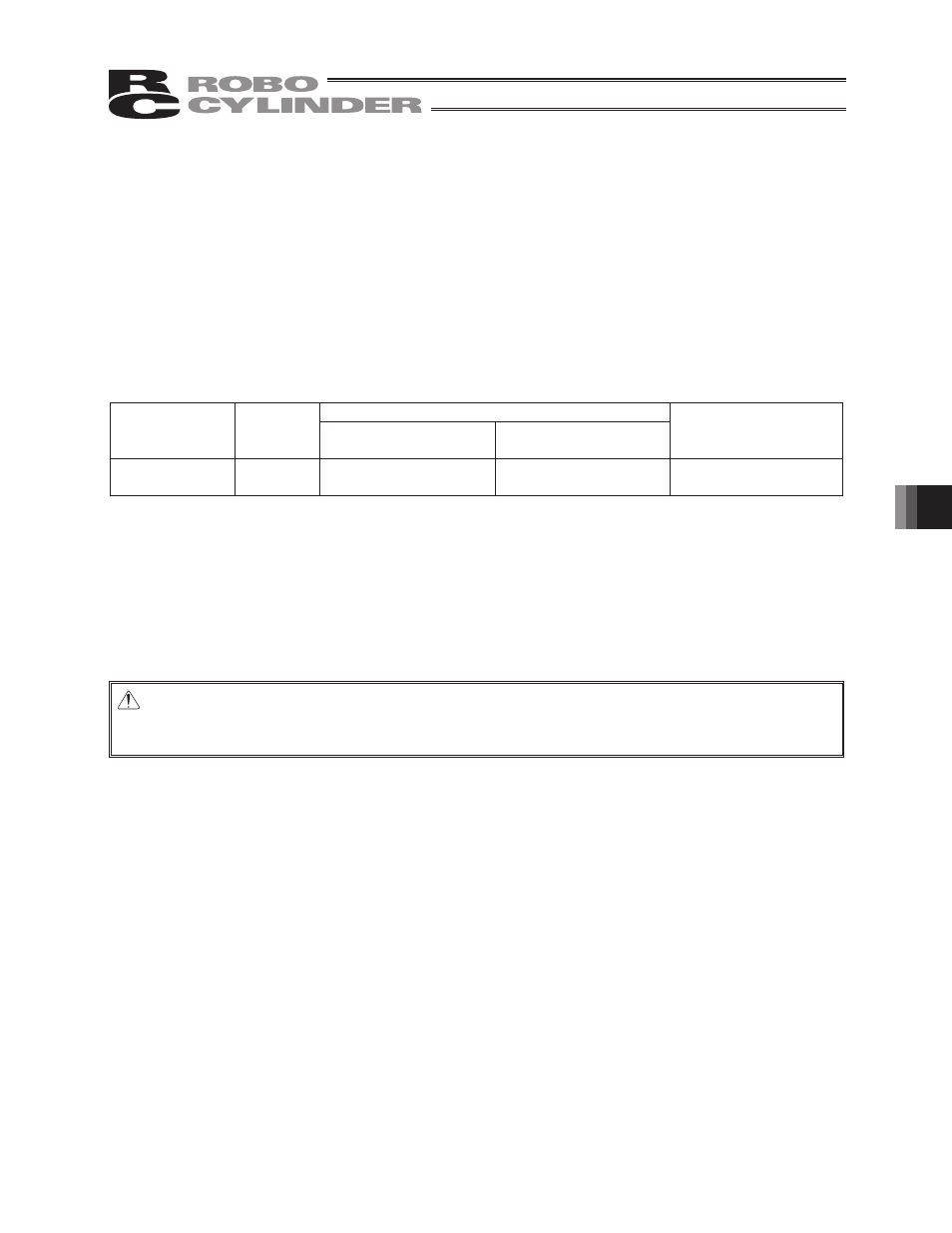

Tightening torque

Tap size and

maximum

screw-in depth

Applicable

bolt

Bolt bearing surface is

steel

Bolt bearing surface is

aluminum

Reamed hole (mm)

M3, depth 5

M3

1.54 N-m (0.16 kgf-m)

0.83 N-m (0.085 kgf-m)

2H7, depth 3 from

base surface

Tightening screws

x Use hexagonal socket bolts for the male threads used to install the base.

x Use of high-tension bolts meeting at least ISO-10.9 is recommended.

x Ensure at least the applicable value specified below for the effective engagement length between the

bolt and female thread:

Female thread is made of steel material

o Same length as the nominal diameter

If female screws are made of aluminum

o Maximum screw-in depth

Caution: Select bolt length carefully. Using a bolt with inappropriate length can damage tap holes,

result in insecure installation of actuator, interfere with the operation of the drive section,

reduce the precision of the device, and cause unexpected accidents.