5 electronics and signal processing – Teledyne 3000ZA2G - Zirconium oxide analyzer User Manual

Page 23

Trace Oxygen Analyzer

Operational Theory

Teledyne

Analytical

Instruments

11

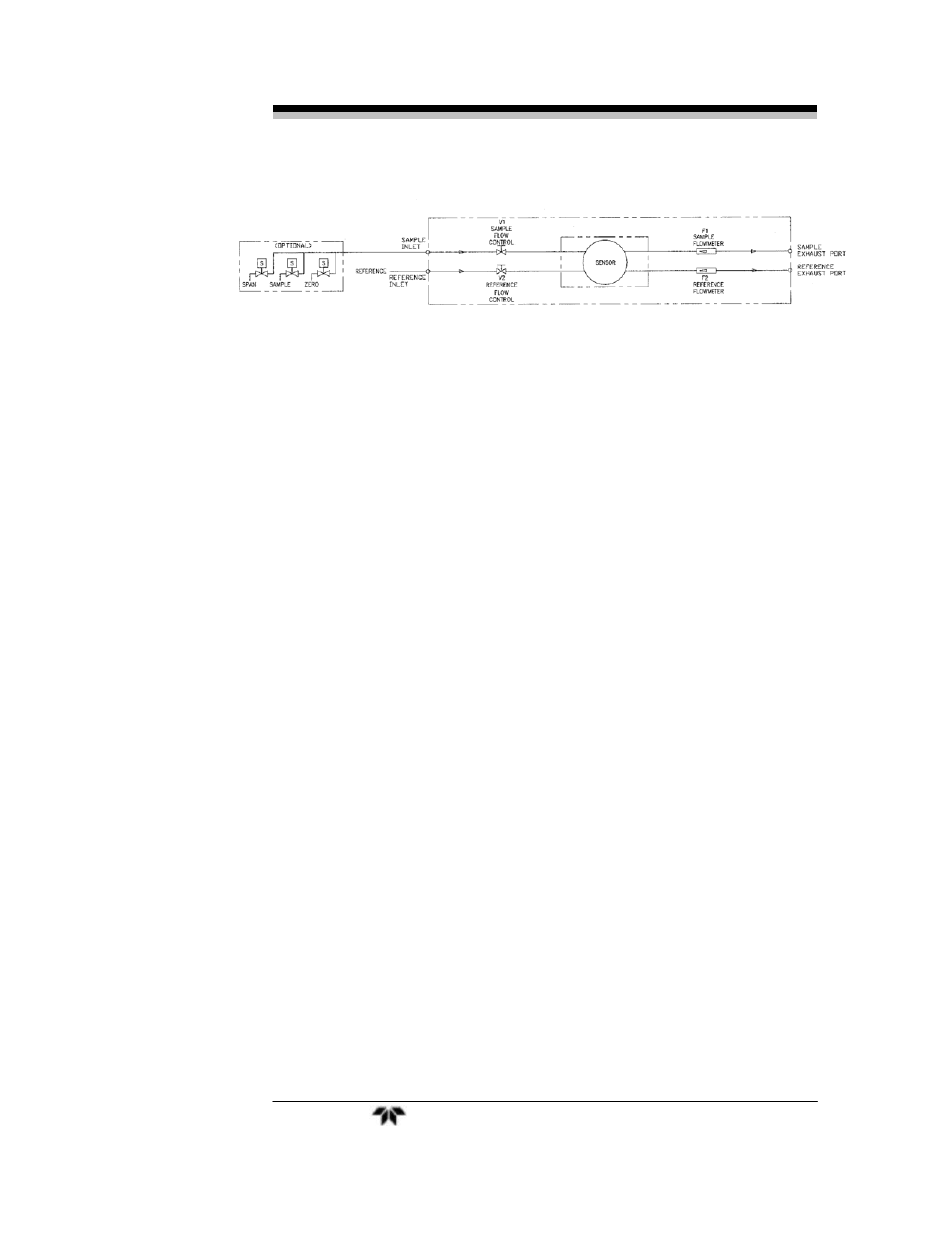

Figure 2-3: Flow Diagram

2.4 Zirconium Oxide Sensor Application Notes

The following sample gases require conditioning prior to entering

the sensors:

Flammable gases such as methane, alcohol and carbon

monoxide may cause a measurement error. They must be

filtered from the sample gas before entering the cell.

Gases containing halogen atoms (F, Cl, Br, etc.) such as

Freon, must be filtered before entering the cell. The sensor

will be damaged by the decomposition of Freon.

Gases containing SOx, H

2

S, silicone vapor and adhesives

must not enter the sensor. These components adversely affect

the performance of the sensor.

Dust and oil should be filtered from the sample gas.

Water vapor in contact with the sensor will damage the

sensor. Use a moisture trap or filter to remove any water

vapor in the sample.

2.5 Electronics and Signal Processing

The Model 3000ZA2G Trace Oxygen Analyzer uses an 8031

microcontroller with 32 kB of RAM and 128 kB of ROM to control all

signal processing, input/output, and display functions for the analyzer.

System power (110/230 VAC) is user selectable from an internal switch.

It is set at the factory for your specific requirement. Figure 2-4 shows the

location of the power supply and the main electronic PC boards.

The signal processing electronics including the microprocessor,

analog to digital (ADC), and digital to analog (DAC) converters are

located on the motherboard at the bottom of the case. The preamplifier

board is mounted on top of the motherboard as shown in the figure.