Recommended water conditions – Fulton FB-S Horizontal Firetube Boiler User Manual

Page 21

The Fulton Companies*FB-S Series Manual*Version 2010-0820 rev. 3/5/13

Page 21

d) If more than one appliance is connected to a common flue or chimney the cross-

section of the chimney should be adequate for the total volume of combustion

products from the appliances.

e) The total horizontal run of the boiler flue should not exceed 25% of the total

vertical rise. There should be an angle more than 15 degrees for the horizontal

run reducing the resistance of the combustion products and avoid rusting by

accumulating condensation in the flue.

f) The installer should check the draft with a meter at 0 to 0.15” W.C pressure with

the burner off. If the pressure is too low, a balancing damper may be used close

to the flue outlet to regulating the pressure of the draft.

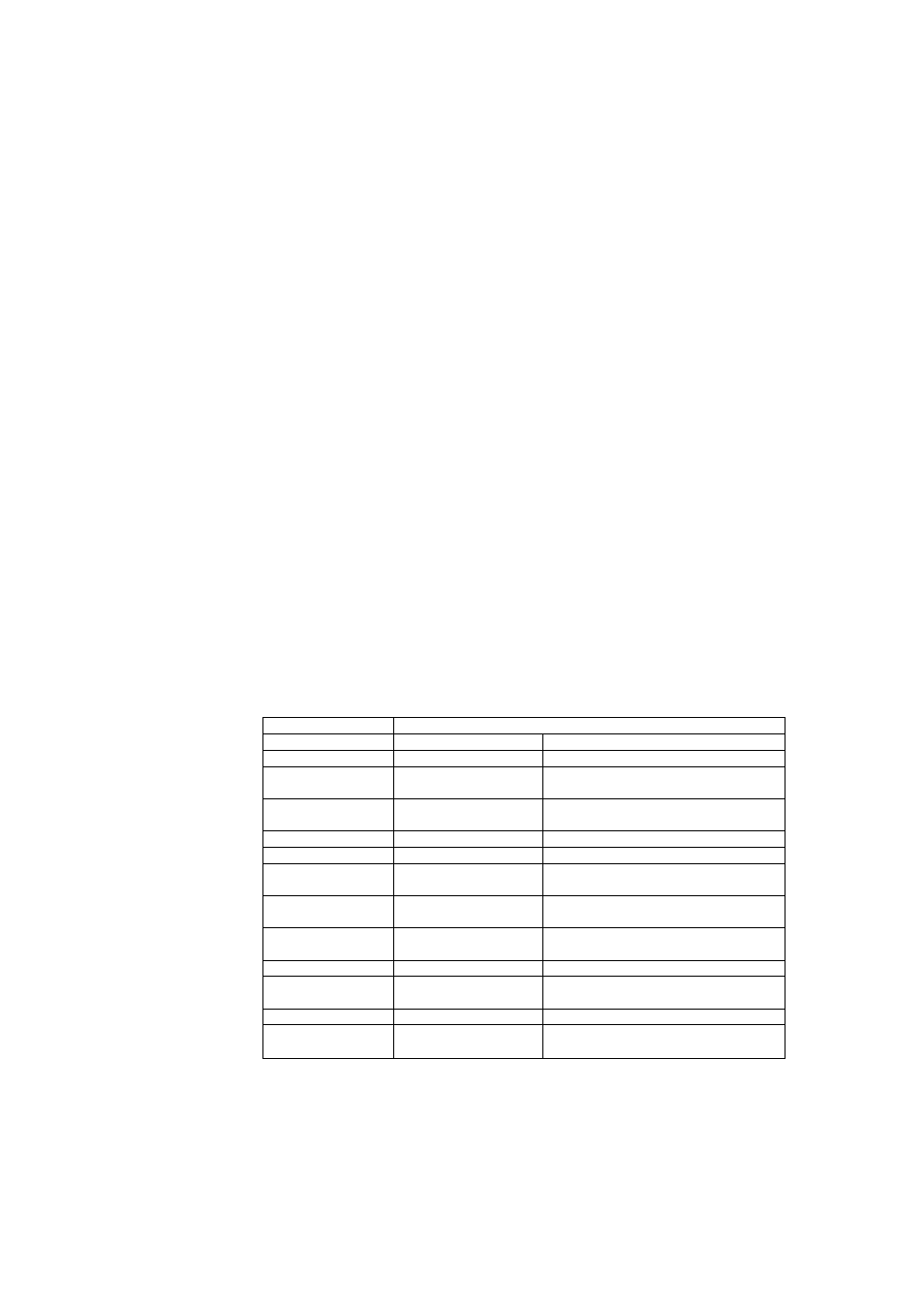

4. Recommended Water Conditions

a) Following are recommendations for feed water and boiler water. Contact your

local water treatment professional for testing and treatment recommendations. It

is very important that a strict water treatment program be followed.

b) It is critical that the boiler pH water chemistry follow the attached schedule

whenever water is in the boiler. Solids that enter in with the feed water will

concentrate in the boiler. A regular schedule of boiler blowdown must be

maintained to prevent high solid concentrations from corroding the vessel or

forming deposits

Carbon Steel

Parameter

Feedwater

Horizontal Boiler/SteamPac Water

pH

7.5-9.5

8.5-10.5

Feedwater

Temperature

140F*

---

Hardness as

CaCO3

< 2ppm

< 15 ppm

Chlorides

---

---

Total Alkalinity

---

< 500 ppm

Total Dissolved

Solids

---

< 3000 ppm

Suspended

Solids

No visual turbidity**

No visual turbidity**

Total Organic

Carbon

No sheen No foam +

No sheen No foam +

Iron

Colorless liquid++

Colorless liquid++

Dissolved

Oxygen

<1 ppm*

ND

Visual Oil

ND

ND

Conductivity

(

µµµµ

S/cm)

---

< 4477

NOTES:

*Feedwater temperatures below 200

o

F will require an oxygen scavenger

** Suspended solids: Take a water sample. After the sample sits for 10 minutes, no solids should be visible.