Luminex 200 System User Manual User Manual

Page 52

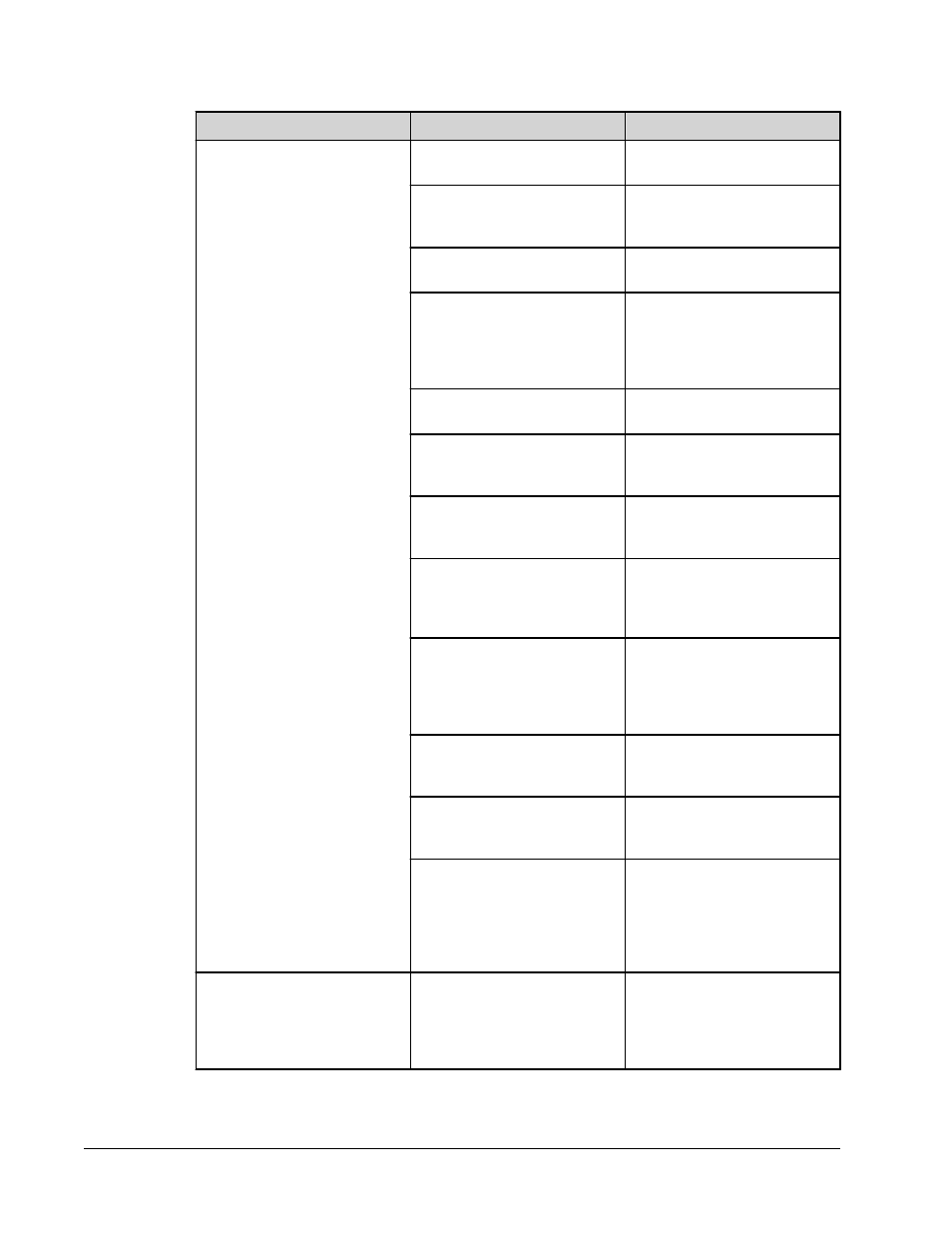

Symptom

Possible problem

Solution

Calibration is slow or fails.

The calibration microspheres

are not fully suspended.

Vortex the calibration vials to

resuspend the microspheres.

Wrong lot number or target

values are entered in Update

CAL Targets dialog box.

Verify that correct lot number

and target values are used.

The system calibrators are in the

wrong well on the plate.

Verify that calibrators are in the

correct well.

Not enough calibrator

microspheres added to the well.

Add at least five drops of

calibrator microspheres to the

well. Hold the vial upside down

at a 90 degree angle to the plate

while dispensing them.

Calibrator lot is expired.

Use a fresh bottle of calibrator

microspheres.

The sample probe height is

incorrect.

Adjust the sample probe height.

See the

section.

The sample probe is clogged.

Clean the sample probe. See

the section titled

There is a partial clog in the

system.

Clean the sample probe, then

flush the system. See the

section titled

There is air in the system.

Verify sample probe height. Run

three Prime commands, two

Alcohol Flush commands, then

three Wash commands with

water.

The waste container is not

vented.

Check that the seal in the waste

container cap is dry and that the

waste container cap is vented.

The waste line was moved

during system operation,

resulting in unstable flow rate.

Verify that the waste line is not

moved during system operation.

Possible problem with the laser.

View the calibration trend report.

Check for dramatic changes in

temperature, sheath pressure,

or voltages. If any of these are

evident on the report, contact

Technical Support.

Zero events collected during

calibration.

There is a problem with fluid

levels.

Check the sheath and waste

fluid levels. Verify that tubing for

both bottles is tightly connected

to the instrument. Check that the

waste bottle cap is vented.

Luminex

®

200

™

System User Manual

40

For In Vitro Diagnostic Use