Liquid Controls SP2800 User Manual

Page 49

45

8-10.5 RS232/RS422 16 Point Serial Input

Example

Example : (S) = Space

Transmit from terminal

Receive from Batcher

D11(S) [Unit 7 activated]

Device #11

FC(S)500(S)KC(S)305

FC 500 KC 305

{Frequency for C (Point 03) is set to 500,}

{K Factor for C (Point 03) is set to 305.}

FC(S)KC(S)(ENTER)

FC KC

{Unit echoes back commands as sent.}

Frequency of C is sent

500

K Factor of C is sent

305

8-11 S

trobe Address Operation

Another method of reading the status of a unit

with either a RS232 or RS422 option is by

means of a separate strobe address and a 3

bit data request code. The strobe address

method does not allow changes of set points.

Theoretically hundreds of units could be

linked together to transmit data from the

Batchers over a serial transmit line. The

units could be assigned any code number

except "00".

The 3 bit data request code would be latched

in at the positive edge of a 3 to 30 VDC strobe

input that remained high a minimum of 25 mil-

liseconds. Requests are processed on a non-

priority basis. Normally data will begin to be

transmitted from the Batcher over the RS232

or RS422 serial transmit lines within 5 msec

unless interrupted by a keypad entry or other

signal input.

Note: No other unit should be brought on line

until data requested has been transmit-

ted.

Note: There are no allowances for Frequency

or K Factor access on units with the 16

Point Option.

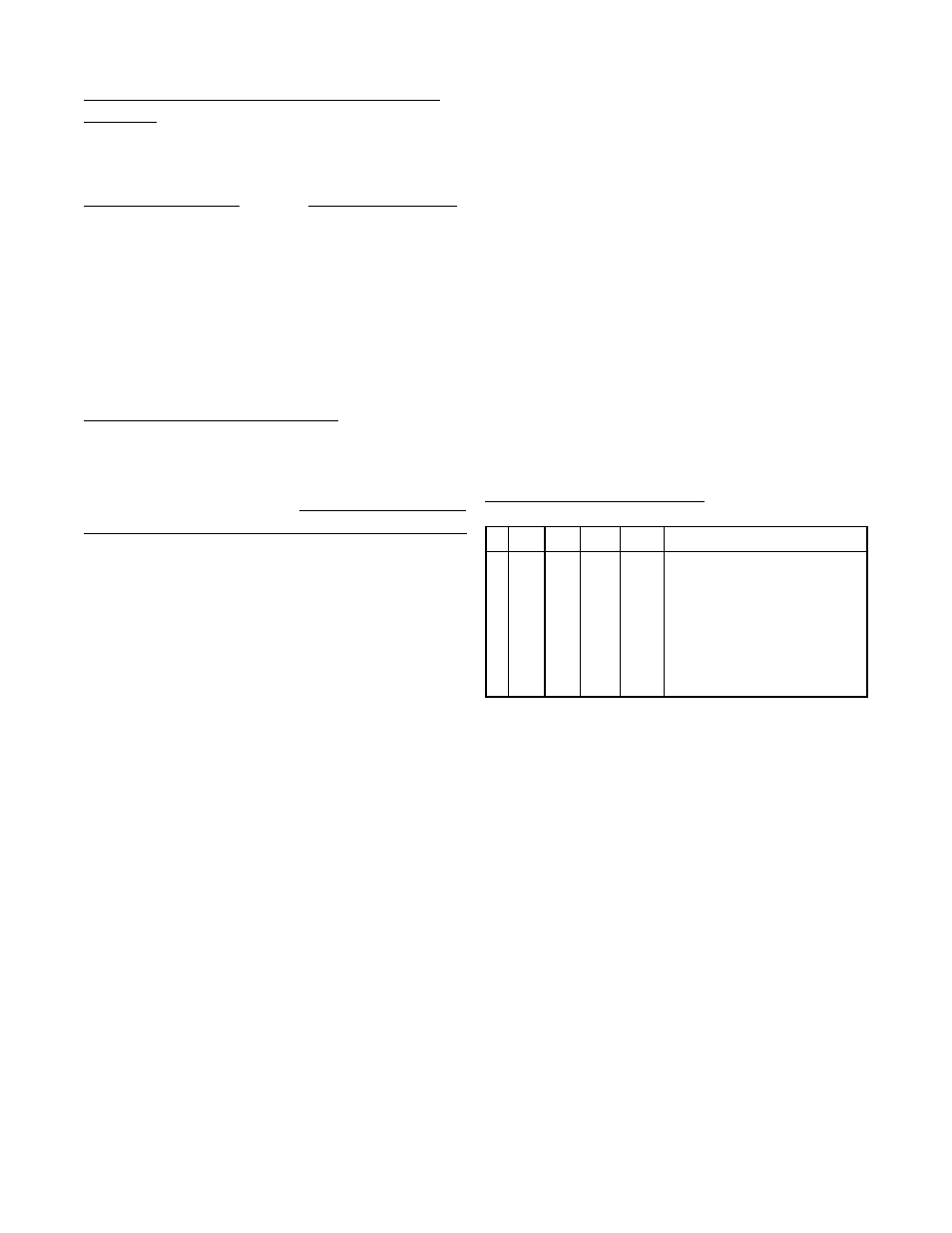

8-11.1 Strobe Input Codes

# DL4 DL2 DL1 Code Description

0

0

0

0

PA

Will transmit Preset value.

1

0

0

1

PW

Will transmit Prewarn value.

2

0

1

0

KC

Will transmit counter K Factor.

3

0

1

1

KR

Will transmit Rate K Factor.

4

1

0

0

DC

Will transmit Count.

5

1

0

1

DT

Will transmit Grand Total.

6

1

1

0

DR

Will transmit Rate

.