Liquid Controls SP2800 User Manual

Page 35

31

4-2 Analog Inputs (continued)

4-2.1 5A: 4-20 mA; 250

Ω

input impedance.

5B: 0-20 mA; 250

Ω

input impedance.

5C: 1-5 VDC; 15 K

Ω

input impedance.

5D: 0-5 VDC; 15 K

Ω

input impedance.

5E: 0-10 VDC; 15 K

Ω

input imped-

ance.

The above inputs take the analog signal and

scale it from 0 to 10000 pulses per second by

using a highly linear voltage to frequency con-

verter. These pulses go to the processor to

be scaled by the K Factors. To determine the

K Factor, see Section 7, Calculating the K

Factor.

4-2.2 6A: Square Law: 4-20 mA; 250

Ω

in-

put impedance.

The Square Law input is a special input that

compensates for non- linear input types. Spe-

cifically, inputs that require square root extrac-

tion to provide accurate count and rate deter-

minations. The input signal is converted to a

0 to 10000 pulse per second input to the pro-

cessor (See Table 4-2 below).

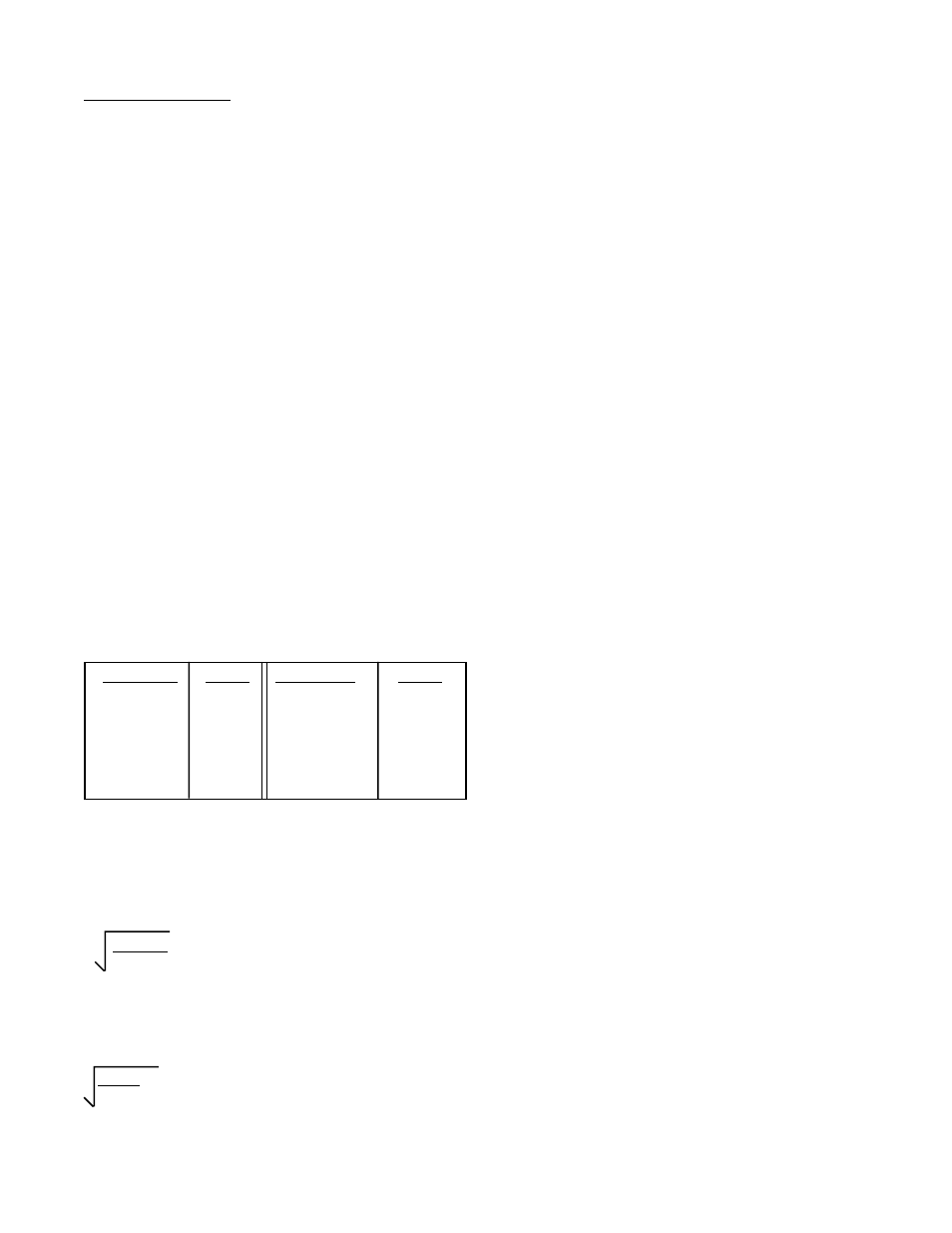

mA Input

Freq.

mA Input

Freq.

4

0000

10

6123

5

2500

12

7071

6

3535

16

8660

7

4330

18

9354

8

5000

20

10000

Table 4-2

To calculate the freq. for a particular input use

the following formula.

mA - 4

x 10000 = Freq. to processor

16

For example: to calculate the frequency for 9

mA Input.

9 - 4

x 10000 = 5590 Freq. to processor.

16

4-2.3 Analog Inputs Exchange

If an analog sensor cannot be obtained that

matches the Batcher input, it is recommended

that the Batcher be returned to have the analog

input module exchanged and recalibrated.

Recalibration should only be attempted by

someone who has the training to open the unit

and work with grounded equipment necessary

to protect the static sensitive CMOS circuitry.

For instructions on how to return the unit for

exchange see Section 2-2.

4-2.4 Analog Inputs Calibration

(All units have been calibrated at the factory)

Warning: This unit contains static sensitive

components. Observe proper precautions!

a) Set the ratemeter at 6 SIG FIG; the

window at 01; and the K Factor at 1.00.

b) Remove the case and locate the analog

input card mounted behind the display

(see Section 6-3).

c) Locate the two 0.3 inch square pots R3

and R15. These numbers should be

silkscreened underneath them on the

board.

d) Input a very accurate low signal and

adjust R3 (left side from the front) so that

the display reads .0001 to 0000.

e) Input a very accurate high signal and

adjust R15 (right side from the front) so

that the display reads 9999 to 10000.

f) Repeat steps d and e until the unit is

reading as close as possible to 0000 on

the low side and 10000 on the high side.

This should only take a few tries.

g) Re-case the unit and setup the Menu as

desired.

If problems occur during calibration please con-

tact the factory for exchange or to arrange for

factory calibration.