Controlled Products Systems Group 9100-080 User Manual

Page 42

9100-065-Z-3-13

40

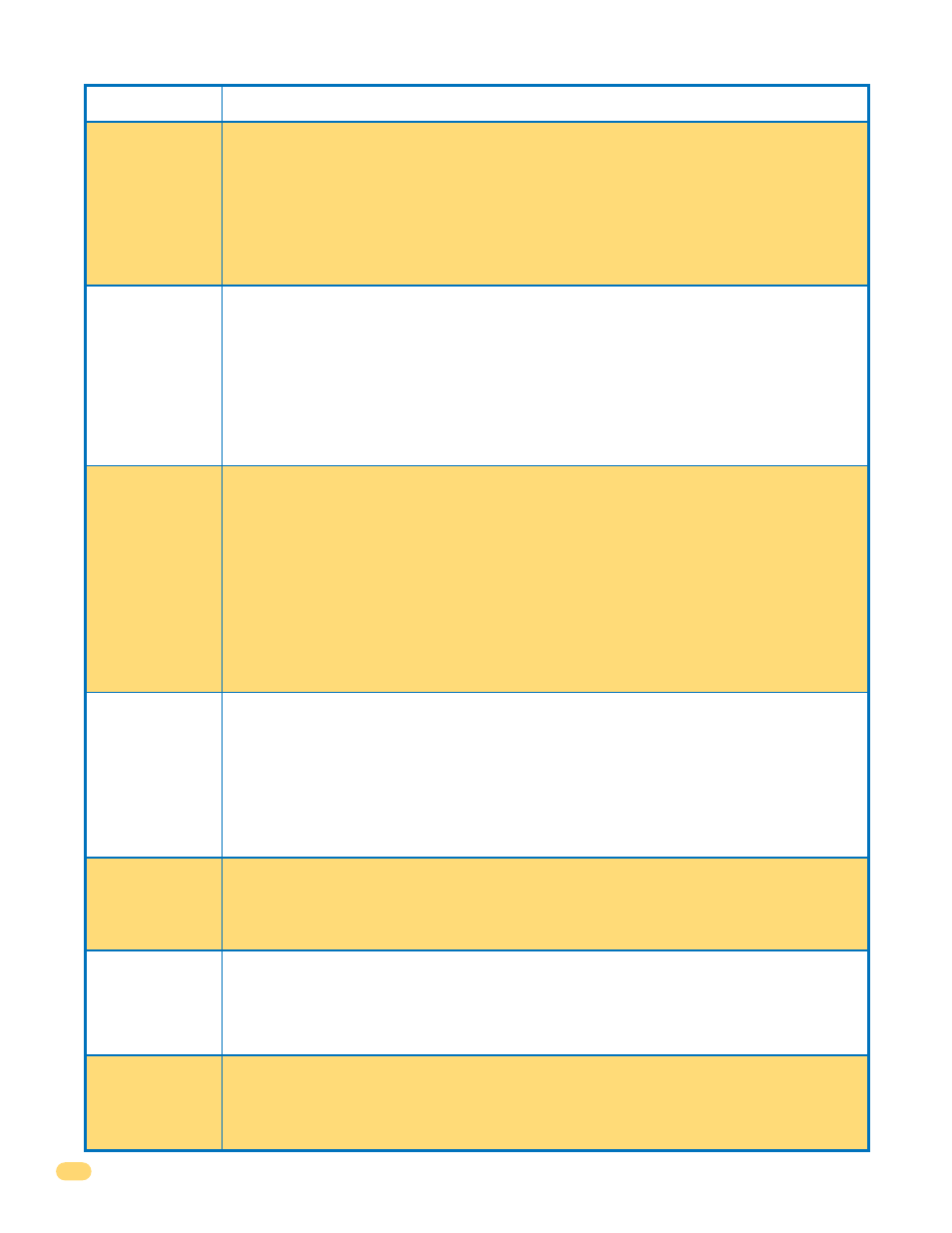

Symptom Possible

Solution

(

s

)

•

Check the input LEDs. Any ON will hold the gate open and indicates a problem with a keying device.

•

Check the secondary safety devices. Any activated will hold the gate open and indicates a problem

with the safety device.

•

Check the loop detectors. Any activated can hold the gate open and indicates a problem with the

loop detector or ground loop.

•

Operator may be in a “soft shutdown.” Activate any keying device to determine if operator returns

to normal operation.

•

If automatic close is desired, be sure SW 1, switch 2 is ON and set timer open from 1-23 seconds.

•

Bypass circuit board and check motor as described on previous page.

Gate opens but

will not close.

Gate closes but

will not open.

•

Operator may be in a “soft shutdown.” Check input LEDs. If any are ON, momentarily disconnect,

then re-connect the wire going to the respective terminal. Operator should open.

•

Check to be sure that the operator is running in the proper direction. Turn power OFF, and then back

ON. Activate a keying device. Operator should run in the open direction. If operator runs in the

close direction, turn power OFF and change direction switch SW 1, switch 1. Go to above section if

operator now opens but will not close.

•

Be sure that the each LED on the control board lights when the keying device connected to the

that terminal is activated. If LED does not light, momentarily place a jumper wire from terminal 1 to

the input terminal being checked. If LED lights and gate opens, problem is with the keying device. If

LED does not light, replace control board.

•

Bypass circuit board and check motor as described on previous page.

•

Check that the clutch is adjusted properly and is not slipping.

•

Disconnect the gate from the gate operator and check that the gate slides freely without any binding.

•

Re-adjust the reverse sensitivity.

•

Check that the magnetic pickup transistors on control board are not obstructed by excess wires.

Electrical interference from excess wires can diminish magnetic field.

•

Check that the magnetic pickup transistors on control board are within 1/8 inch of the clear plastic

protective cover above the black plastic magnetic spring assembly on the main shaft.

•

Continue troubleshooting or replace the circuit board.

Gate opens a short

distance, then stops

and reverses.

Gate closes then

re-opens.

Gate starts to close,

then reverses to

open.

Alarm chirps once

every 5 seconds.

Operator will not

run.

Alarm is sounding.

Operator will not

run.

•

Check that the clutch is adjusted properly and is not slipping.

•

Re-adjust the reverse sensitivity.

•

Disconnect the gate from the gate operator and check that the gate slides freely without any binding.

•

Check the loop detector LEDs and input LEDs. Any that flash ON will cause the gate to reverse.

•

Check the Magnetic Sensor LEDs on the circuit board. If either LED is not blinking as the operator is

running, check that the magnetic pickup transistors are within 1/8 inch of the protective plastic

cover above the magnet assembly on the main shaft.

•

Continue troubleshooting or replace the circuit board.

•

Operator has been in a “hard shutdown” condition in excess of 5 minutes. Reset button must be

pushed to return operator to normal operation, see Section 6.2 Shutdown Conditions, pages 35-36.

•

Operator is in a “hard shutdown” condition. Reset button must be pushed to return operator to

normal operation, see Section 6.2 Shutdown Conditions, pages 35-36.

•

Check for any input or loop detector LED’s that are ON.

•

Check that the operator is running in the proper direction (see “gate closes but will not open”).

•

Check the SELF-TEST DIP switch setting, SW 1, switch 6 should be OFF.