2 dip-switch sw 1 and sw 2 settings, Sw 1 (left 8 switches), Switch function setting description – Controlled Products Systems Group 9100-080 User Manual

Page 24

9100-065-Z-3-13

22

7-OFF

7-OFF

7-ON

7-ON

8-OFF

8-ON

8-OFF

8-ON

Gate Open

Back-Off

Position

Normal Setting. Gate fully opens.

Gate stops short 1” from full open position. Used for a reversing edge device.

Gate stops short 2” from full open position. Used for a reversing edge device.

Gate stops short 3” from full open position. Used for a reversing edge device.

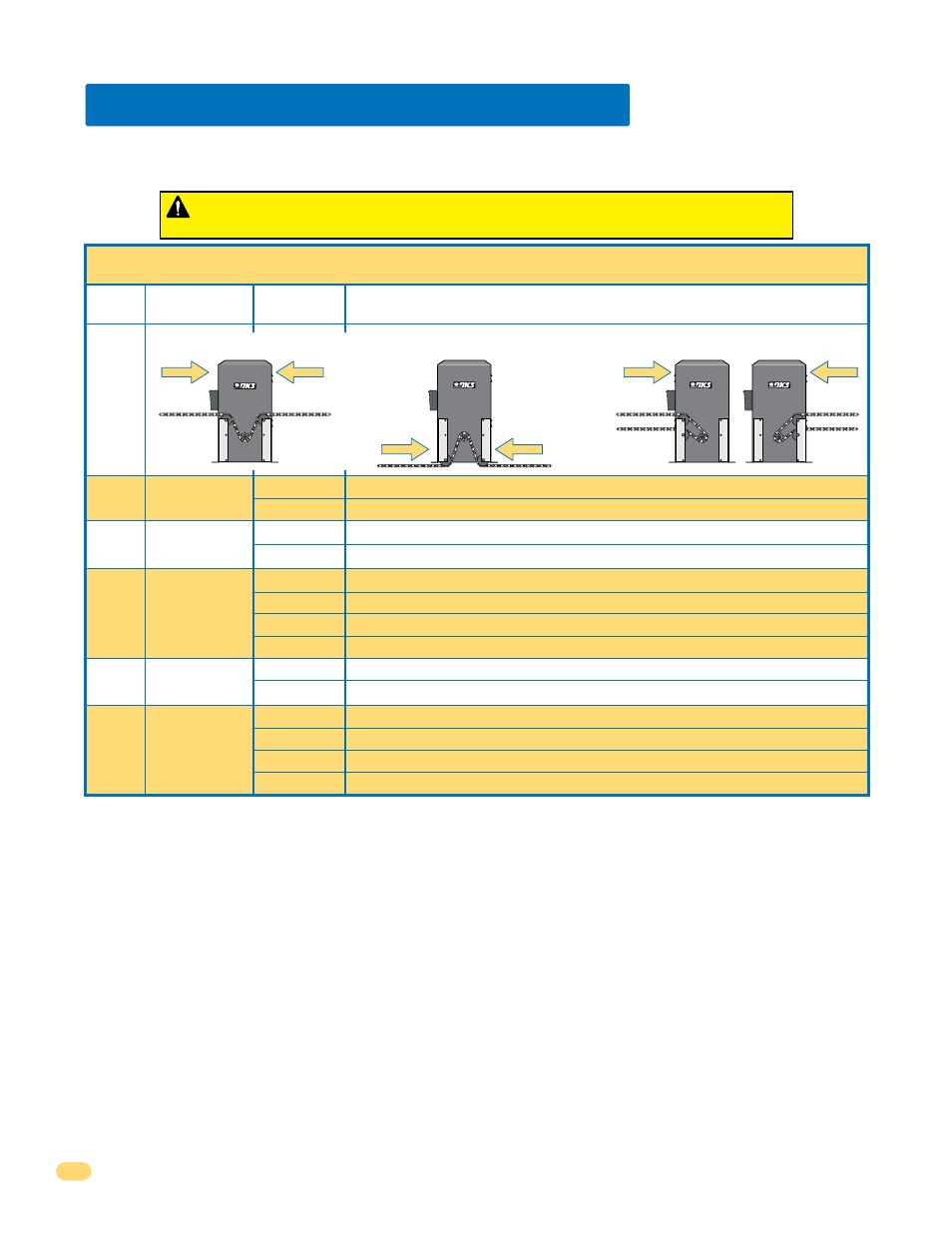

3.2 DIP-Switch SW 1 and SW 2 Settings

The two DIP-switches located on the circuit board are used to program the operator to operate in various modes and to turn on

or off various operating features. Whenever a switch setting is changed, power to the operator must be turned OFF and then

turned back on for the new setting to take affect. Check and review ALL switch settings prior to applying power to the operator.

SW 1 Switch 1

Must OPEN the gate upon initial AC power up and open command. If the first open command begins to close the

gate, turn AC power off and reverse this switch. Opening direction will vary depending on the type of installation (See above).

SW 1 Switch 2

Turns the auto-close timer on or off. Can be adjusted from 1 to 23 seconds to close gate.

SW 1 Switch 3

This switch should be left in the OFF position when the slide gate is running on a level track and the gate does not

coast after it has stopped. If the gate is on an incline, turning this switch on will apply a small DC voltage to the motor windings

after the gate has stopped. This applies braking power to the motor to prevent the gate from “coasting” after it has stopped.

SW 1 Switches 4-5

These work in conjunction with each other and determine when the relay on the board will be activated. This

relay can be used as a switch for various functions such as illuminating a warning light when the gate is moving, or turning on a

green light when the gate is full open. If a magnetic lock is used with the gate operator, these switches must be set for magnetic

lock operation which limits the relay to activate only when the gate is opening and full open.

SW 1 Switch 6

This switch is a self-test feature that checks various functions of the circuit board and is used for bench test only.

Do not run this test with the operator connected to the gate.

SW 1 Switches 7-8

These work in conjunction with each other and determine if the operator will stop the gate at the full open

position, or if the gate should stop 1, 2 or 3 inches short of the full open position. Needed only when using a reversing edge

entrapment protection device on the opening edge of the gate with an end post as the physical stop.

Switch

Function

Setting

Description

SW 1 (Left 8 Switches)

OFF

ON

4-OFF

4-OFF

4-ON

4-ON

5-OFF

5-ON

5-OFF

5-ON

Auto-Close

Timer

Relay Activation

and

LED Indicator

Light Activation

2

1

Motor

Hold

OFF

ON

3

4 and 5

7 and 8

Normal Setting. No voltage to motor when gate is stopped (Level gate).

Voltage applied to motor always. Keeps inclined gate from coasting when stopped.

Auto-close timer is OFF. Manual input required to close gate.

Auto-close timer is ON. Adjustable from 1-23 seconds to close gate.

OFF

ON

Self-Test

6

Normal Setting.

Runs self-test. Caution: Bench testing ONLY!

Relay activates and LED is ON when the gate is fully open.

Relay activates and LED is ON when the gate is not closed.

Relay activates and LED is ON when the gate is opening and open.

Relay activates and LED is ON when the gate is opening and closing.

Changes the direction the operator will open/close the gate depending on the different chain configurations.

Opening

direction

using ON

setting.

Opening

direction

using OFF

setting.

Mount

Front

Opening

direction

using OFF

setting.

Opening

direction

using ON

setting.

Post

Mounts

Center or

Opens

with

ON

setting.

Mounts

Right

All Rear

Opens

with

OFF

setting.

Mounts

Left

All Rear

Every time the operator is powered up, the First open command will automatically run “Multiple

gate cycles” that will locate and remember the gate’s open and close positions (See page 24).