Technical information/ troubleshooting – Controlled Products Systems Group 1601-080 User Manual

Page 34

1601-065-M-05-07

installation guide 35

technical information/troubleshooting

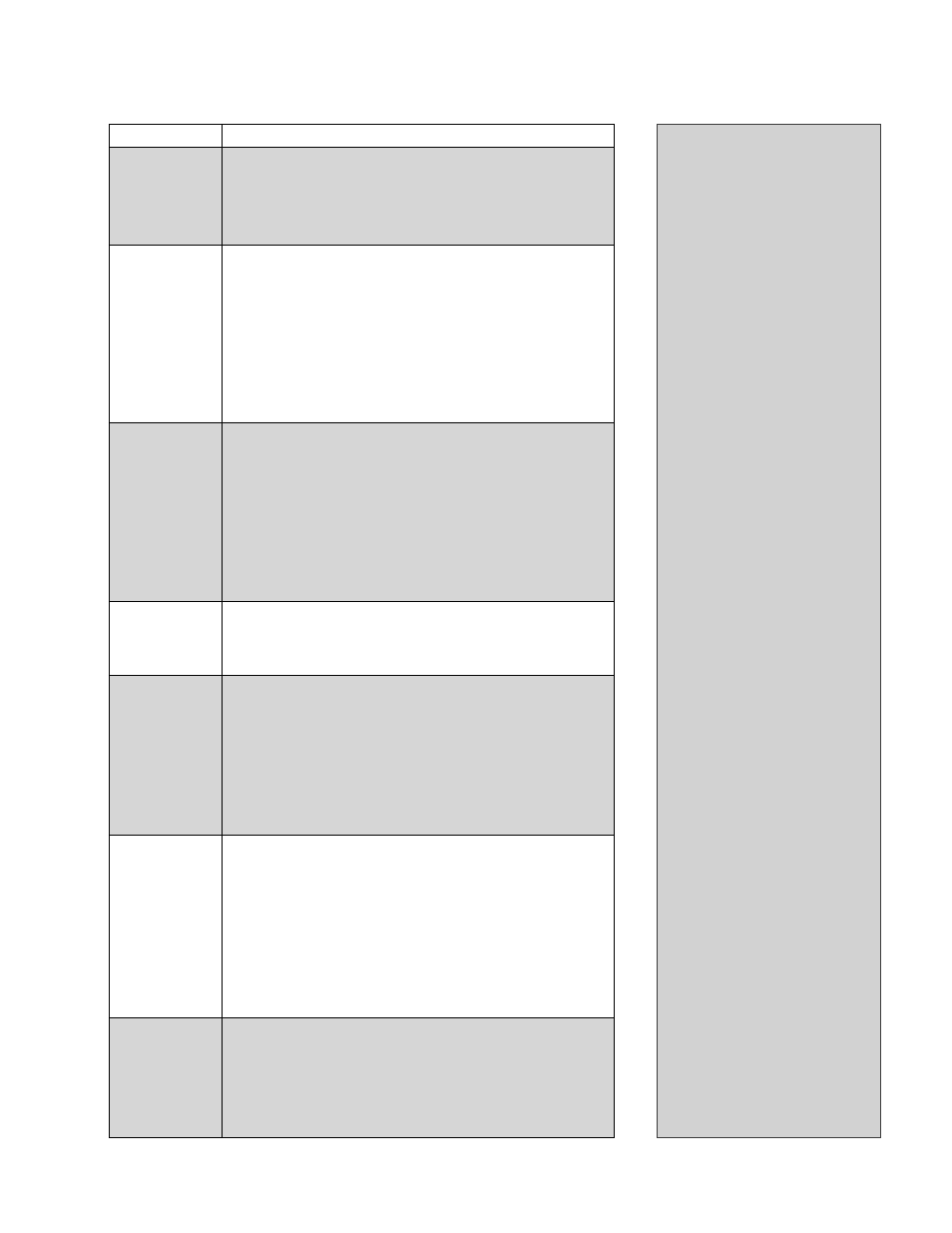

Condition

Possible Solution

Operator will not

run – power LED

on control board

is OFF.

·

Be sure AC power switch is on.

·

Check for 117 VAC with a voltmeter at control board terminals 1 and

2. If voltage measures 0, check power supply to operator or check

terminal strip. If voltage measures OK, replace control board.

Operator will not

run – power LED

on control board

is ON.

·

Momentarily jumper terminal 6 to terminal 14. If input LED does not

come ON, check terminal strip or replace control board. If LED does

come on, go to the next step.

·

Momentarily jumper terminal 2 to terminal 3 (Caution – High Voltage).

The motor should run.

·

Momentarily jumper terminal 2 to terminal 4 (Caution – High Voltage).

The motor should run in opposite direction of above.

·

If motor does not run in either or both steps above, bad motor, motor

capacitor or wiring to motor.

Arm rotates

up, but will not

rotate down.

·

Check LEDs on terminals 6, 7 and 9. Any of these ON will hold the

arm in the UP position. This indicates a shorted input.

·

Check the LEDs on the loop detectors. Any ON will hold the arm in

the UP position. Possible loop or loop detector problem.

·

If auto timer is not used (SW1, switch 7 off ), check to be sure SW1,

switch 6 is in the ON position. This will cause terminal 6 to rotate

the arm down when it is activated.

·

Check to be sure SW1, switch 4 is ON. This will cause terminal 8

activation, then deactivation to rotate arm down.

Down input /

down loop will

not rotate arm to

down position.

·

Check to be sure SW1, switch 4 is in the ON position.

·

Down input must be activated, and then deactivated to cause arm

to rotate down.

Loop detector LED

is on continuously.

·

Activate the reset switch on the loop detector.

·

Decrease loop detector sensitivity.

·

Check loop wire for resistance to ground with meg-ohm meter.

Should be 100 meg-ohms or higher. If less than 50 meg-ohms,

replace loop wire.

·

Be sure loop lead-in wire is twisted at least 6 turns per foot.

·

Be sure all loop connections are soldered.

·

Replace loop detector.

Loop detector LED

never activates.

·

Increase loop detector sensitivity.

·

Check continuity of loop wire. Should be 0 ohms. If continuity

check indicates anything other than 0 ohms, check all connections.

Replace loop wire.

·

Move loop detector board to the other loop detector port on the

control board, and then check loop operation. If loop detector still

fails, replace loop board.

·

If loop detector operates OK in the other loop port, replace control

board.

Battery back-up

system will not

raise arm upon

power outage.

·

Check to be sure that the 2340-010 battery back-up control board

switch settings are set as described in section 2.x.

·

Check that the back-up system toggle switch is in the ON position.

·

Check the batteries for proper voltage, replace if necessary.

·

Replace the 2340-010 control board.

Have the following diagnostic tools

available: VOM meter with minimum

voltage memory or min-max range to

check voltage and continuity. Meg-

ohm meter capable of checking up to 500

meg-ohms of resistance to properly check

ground loop integrity. A malfunction can

be isolated to one of the following:

•

Gate Operator

•

Loop System

•

Keying Devices

Use caution when checking high volt-

age areas: terminals 1 through 6, the

motor capacitor and the motor.

Check the input indicator LEDs. They

should only come ON when a keying

device (card reader, push button, etc.) is

activated. If any of the input LEDs are

ON continuously, this will cause the op-

erator to hold the arm up. Disconnect

the keying devices one at a time until

the LED goes OFF.

A malfunction in a loop or loop detec-

tor can cause the gate operator to hold

open, or not detect a vehicle when it is

present over the loop. Pull the loop de-

tector circuit boards from the loop ports

on the operator circuit board. If the

malfunction persists, the problem is not

with the loop system. For more informa-

tion refer to the loop detector instruc-

tion sheet and the DoorKing Loop and

Loop Detector Information Manual.

Check to be sure that there are no

shorted or open control wires from the

keying devices to the gate operator. If a

keying device fails to raise the arm, mo-

mentarily jumper across terminals 6 and

14 on the operator circuit board. If the

arm rises, this indicates that a problem

exist with the keying device and is not

with the operator.

Check the high voltage supply. A volt-

age drop on the supply line (usually

caused by using too small supply volt-

age wires) will cause the operator to

malfunction. Refer to the wire size chart

on page 10.