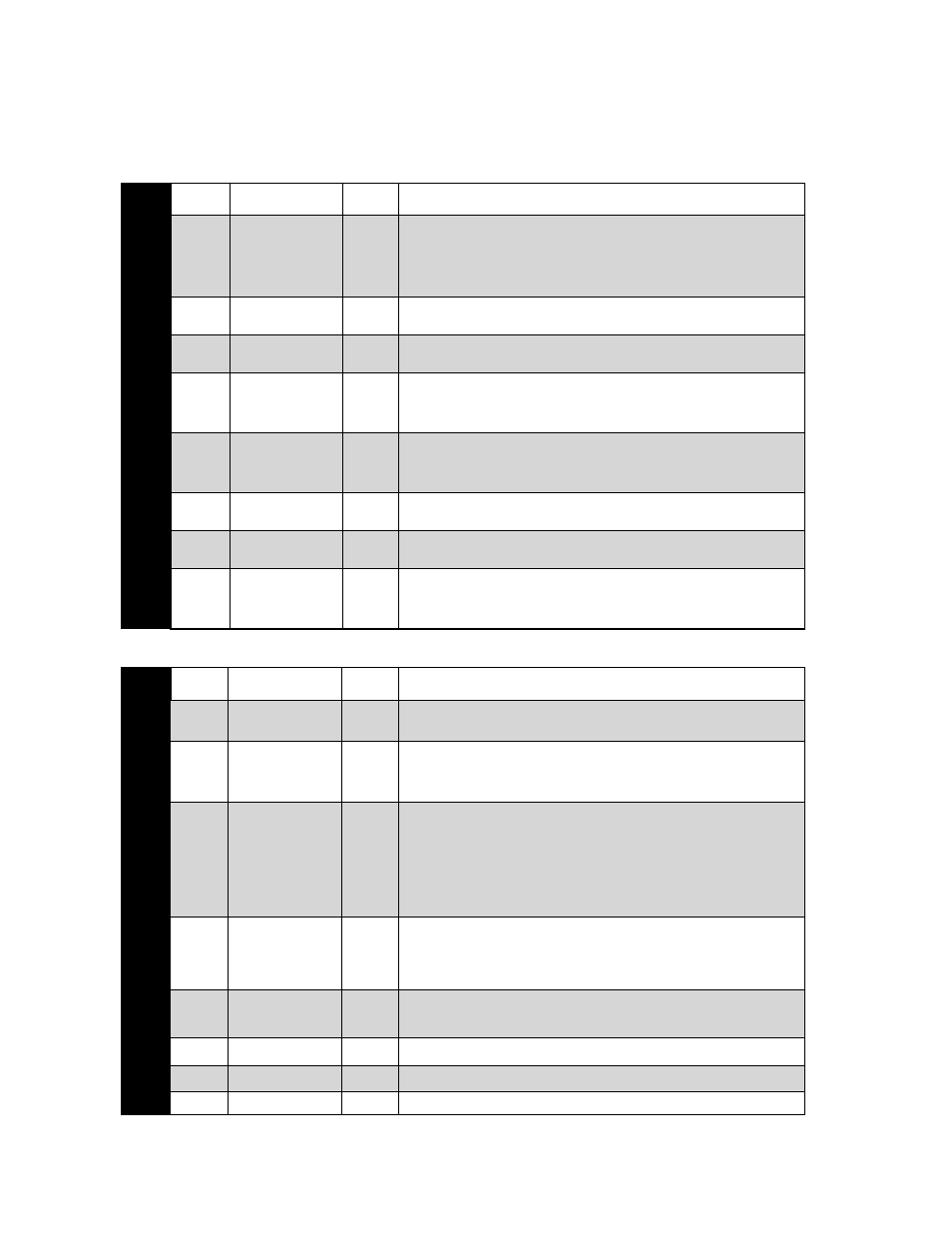

Settings/ switch descriptions & functions, Sw1 (top switch) sw2 (bottom swit ch) – Controlled Products Systems Group 1601-080 User Manual

Page 27

1601-065-M-05-07

28 installation

guide

settings/switch descriptions & functions

Switch

Function

Setting

Description

1

Down Active when

arm is full up

Down Active

when arm is mov-

ing up or is up

OFF

ON

Activation and then deactivation of the down loop or down / reverse input will

cause the arm to rotate down ONLY if the deactivation occurred after the arm

reached the FULL UP position.

Activation and then deactivation of the down loop or down / reverse input will

cause the arm to rotate down AFTER reaching the FULL UP position regardless

of when the deactivation occurred.

2

Self Test

OFF

ON

Normal setting. Self-test is turned off.

Runs self test.

3

Gear Box Travel

OFF

ON

Normal setting. Operator uses 360° of gearbox.

Alternate setting. Operator uses 180° of gearbox.

4

Down / Reverse

Loop and Input

OFF

ON

Down / Reverse loop and input will function as a REVERSE loop and REVERSE input.

Normal setting. Down / Reverse loop and input will function as a down input

and cause the arm to rotate down upon deactivation of the input. See SW 1,

switch 1 for additional information.

5

Relay 1 Activation

OFF

ON

Normal setting. Relay activates when the DOWN loop detector (DoorKing

plug-in detector only) senses a vehicle presence.

Relay activates when the UP loop detector (DoorKing plug-in detector only)

senses a vehicle presence.

6

Up Input Function

OFF

ON

Up Input will raise arm and/or reset the down timer. Input will not lower the arm.

Up Input will raise arm if it is down, or will lower arm if it is up.

7

Time Delay

OFF

ON

Time delay to lower arm is OFF.

Time delay to lower arm is ON.

8

UP Loop Port

Output

OFF

ON

Output of the loop detector plugged into the UP loop port is switched to ter-

minal 7 for connection to other input terminals.

Normal setting. Output of the loop detector plugged into the UP loop port

will raise arm when activated.

The DIP-switches located on the circuit board are used to set operating modes and to turn ON or OFF various operat-

ing features. SW1 is the top switch, SW2 is the BOTTOM. When a switch setting is changed, power to the operator

must be turned OFF, and turned back on for the setting to take affect. Check and review ALL switch settings prior to

applying power to the operator.

SW1 (top switch)

SW2 (bottom swit

ch)

Switch

Function

Setting

Description

1

Operator Mode

l

OFF

Switch must be set OFF for model 1603 operators.

2

Multiple Input

Memory

OFF

ON

Normal Operation. Operator will respond to most recent command. If mul-

tiple UP inputs are received, the NEXT down command will lower arm.

Remember multiple inputs. SW 1, switch 4 must also be on.

3

Multiple Input

Memory Options

OFF

ON

Second Car Down – If a vehicle is on the down loop when the 1601 receives

another UP command, the operator will ignore the close command when

the first vehicle clears the down loop and will require the second vehicle to

clear the down loop to lower the arm.

Multiple Up Commands – The 1601 will count the number of UP commands

it receives and will require a matching number of down commands to low-

er the arm whether or not down loop is active.

4

Stop Loop

Function

OFF

ON

Normal Operation. The down loop is inactive DURING the down cycle.

Stop Loop – If a vehicle activates the down loop during the down cycle, the

arm will STOP. An UP command will raise the arm, or the arm will continue

down AFTER the loop is cleared.

5

Reverse Delay

ON

Instant Reverse – Arm reversal is delayed approximately .1 second when a

reverse input (terminal 9) is received during the down cycle.

6

Direction

OFF

Changes direction of arm rotation.

7

Spare

OFF

No Function. Leave in OFF position.

8

Spare

OFF

No Function. Leave in OFF position.