Fluid Components International CMF Series Manual Electronics Setup and Menus User Manual

Page 15

Commissioning

Fluid Components Intl

Document 06EN003327 Rev. -

65

FlexCOR

™

Model CMF Series

Service mode

The service mode menu can be used to check the flowmeters operation or as diagnostic tools

for trouble shooting.

Flow rate indicates the actual flow rate in %, while tests are being conducted in SERVICE MODE.

Low flow cut-off can be used to supress fluctuating flow transients while experimenting.

Current output can be used to simulate a given flow, temperature, density signal etc. The feature

can be used to check/calibrate connected equipment. Under current output forced a value

between 0 and 24 mA can be set.

If 3 current outputs are used the function can also be used for identification of the individual outputs

by activating these in turn.

Digital output can also be simulated. If the output is selected as limit functions or batch a high or

low state can be simulated. If the digital output is used as flow, density or temperature output, a

signal of 1 to 12,500 Hz can be simulated.

Relay output is used to simulate the relay as on or off.

Special information is used for making diagnosis of the sensor function under the present

operating conditions. This makes it possible to reveal errors caused by errors in the sensor itself

or errors due to application conditions disturbing the sensor function.

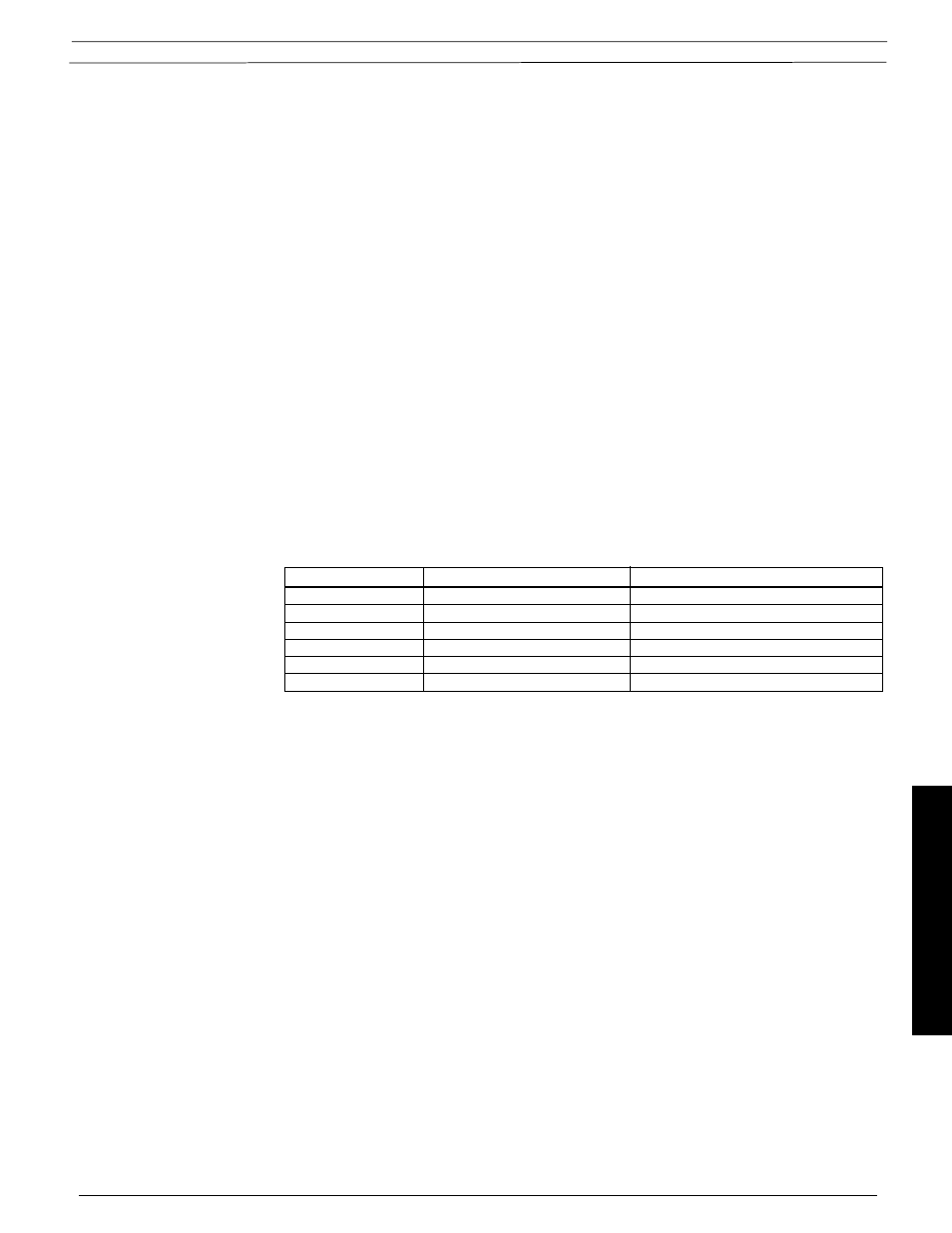

Driver signal indicates the current which is necessary to drive the sensor. The driver current is

dependant of sensor size. In the table below the typical values for normal operation conditions are

displayed. The driver current will increase if there is damping in the application, such as air/gas

bubbles, hydraulic generated noise such as flow pulsations or dampning created by mechanical

noise such as vibrations. The driver output circuit can deliver 36 mA maximum.

Size

Driver frq. [Hz]

Driver current [mA]

CMF - A

120

12

CMF - B

110

7

CMF - C

135

15

CMF - D

165

15

CMF - E

125

10

CMF - F

125

12

Pick-up 1/2 amplitude indicates the signal level at the two pick-up’s. In normal operation

conditions the level should be greater than 50 mV. A lower value indicates damping in the system

and can be due to air/gas bubbles in the sensor.

The signal on pick-up 1 and 2 should be within the same value ±20 mV. A bigger difference

indicates noise in the system due to hydraulic or mechanical errous conditions.

Sensor frequency gives the resonant frequency of the sensor in Hz. The frequency is dependent

on dimension as well as the density of the liquid measured, see table below. Values more than

±20 Hz away of the values in the table indicate problems, check cabling, connection and operation

conditions.

Sensor temperature gives the actual temperature of the sensor. The function can be used to see

whether possible errors occur because the sensor is exposed to an excessively high temperature.

Futhermore, errors due to missing/wrong connection of the temperature transmitter between

sensor and converter can be detected.

Sensor zero can be used to check whether the zero point of the meter is satisfactory.

Operating time indicates how many days the signal converter has been in operation.

Service mode

Menu description