Burkert Type 2300 User Manual

Page 38

38

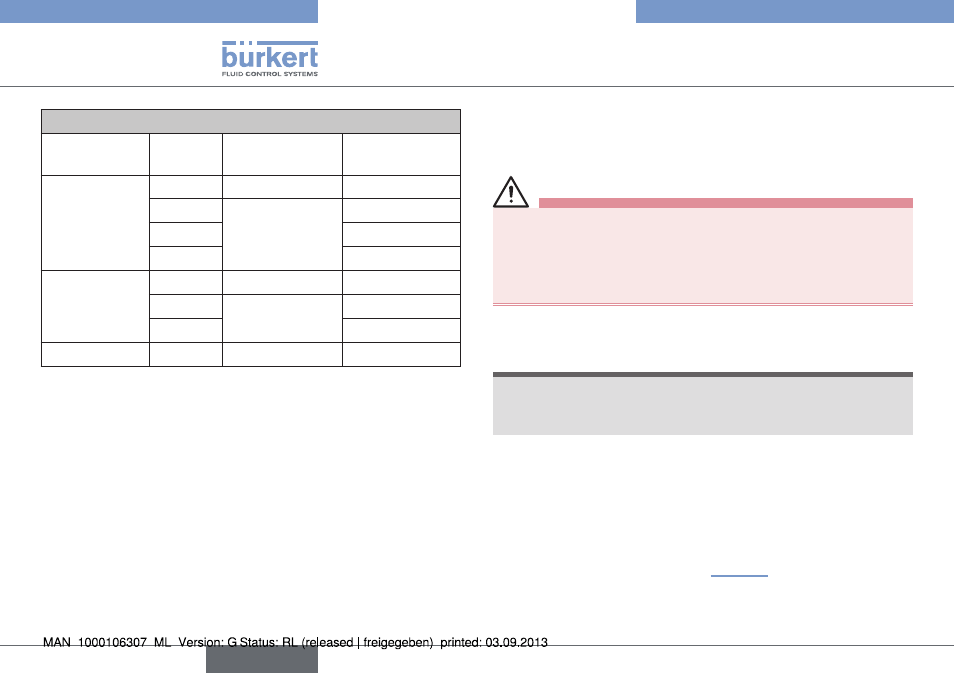

Maintenance, cleaning

Tightening torques of spindle

Spindle

diameter

Orifice

body

Material of

spindle guide

Tightening

torque [Nm]

10 mm

PEEK

6

15

1.4401 / 1.4404

/ 316L

15

20 – 25

25

32

50

14 mm

PEEK

15

25

1.4401 / 1.4404

/ 316L

25

32 – 50

60

22 mm

65

1.4401 / 1.4404

60

Tab. 19: Tightening torques of spindle

Installing the control cone

→

Attach new control cone to the spindle.

→

Align bores of the control cone and spindle.

→

Support control cone on the cylindrical part with the aid of a

prism or something similar.

→

Put on dowel pin and carefully knock in with a hammer.

→

Position the dowel pin in the centre of the spindle axis.

Install the actuator (with control unit) on the valve body

→

Check the graphite seal and if required, replace it.

WARNING!

Danger if incorrect lubricants used!

Unsuitable lubricant may contaminate the medium. In oxygen

applications there is a risk of an explosion!

• In specific applications, e.g. oxygen or analysis applications, use

appropriately authorised lubricants only.

→

Grease nipple thread before re-installing the actuator (e.g. with

Klüber paste UH1 96-402 from Klüber).

NOTE!

Damage to the seat seal or the seat contour!

• When installing the actuator, ensure that the valve is in open

position.

→

Control function A:

Without unit control: pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

With unit control: open the valve according to the operating

instructions for the control unit.

→

Screw actuator into the valve body.

Observe tightening torque (see “Tab. 20”).

english

Type 2300