Before installation – Burkert Type 2300 User Manual

Page 23

23

Installation

8.2.

Before installation

• The angle-seat control valve can be installed in any installation

position, preferably with the actuator in upright position.

• Before connecting the valve, ensure the pipelines are flush.

• Make certain the flow direction is correct (Flow direction always

below seat).

8.2.1. Preparatory work

→

Clean pipelines (Sealing material, swarf, etc.).

Devices with welded body

Remove the control unit from the actuator (if present):

→

Clamp the valve body in a holding device.

→

Loosen the fastening screws (2x).

→

Remove the control unit upwards.

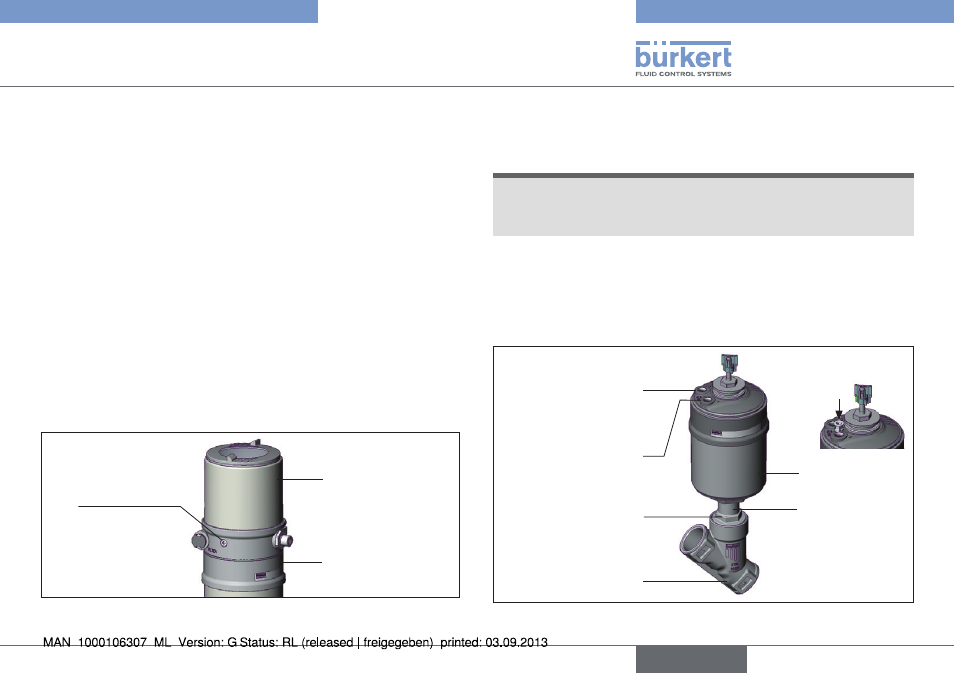

Fastening screw

(2x)

Control unit

Actuator

Fig. 16: Disassembly the control unit

Remove the actuator from the valve body.

→

Install collet (white grommet) in pilot air port 1.

NOTE!

Damage to the seat seal or the seat contour!

• When removing the actuator, ensure that the valve is in open

position.

→

Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→

Using a suitable open-end wrench, place the wrench flat on the

pipe.

→

Unscrew the actuator from the valve body.

Actuator

Nipple

Valve body

Flats for open-end

wrench

Pilot air port

CFA, CFB, CFI

Exhaust air port

CFA, CFB

Pilot air port CFI

2

1

Install collet:

Fig. 17: Installation

english

Type 2300