Pneumatic connection – Burkert Type 2300 User Manual

Page 27

27

Installation

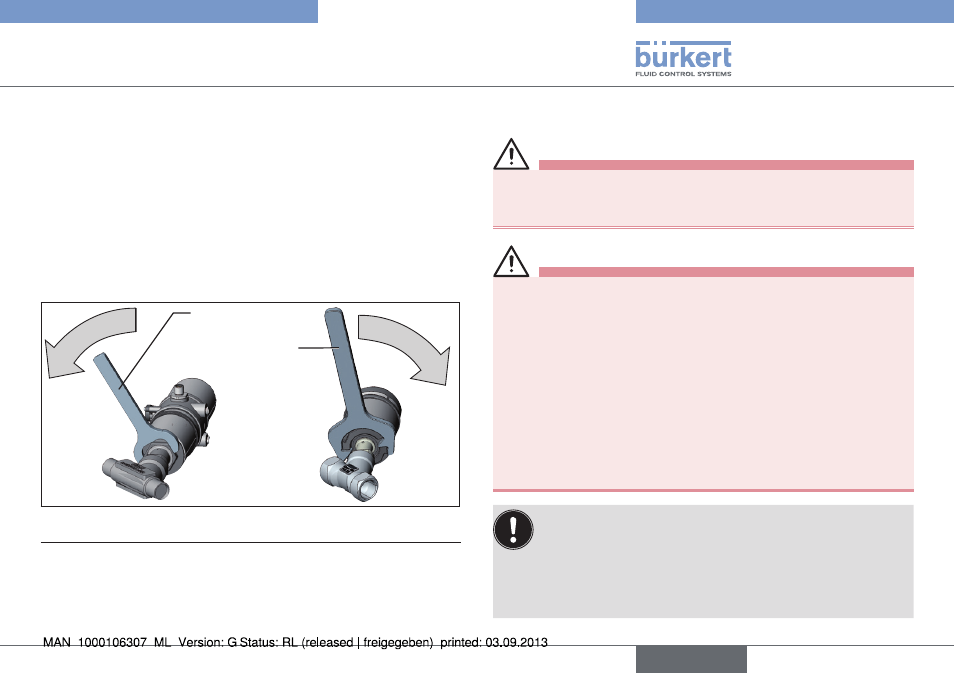

Actuator with hexagon:

→

Place suitable open-end wrench on the hexagon of the actuator.

→

Rotate counter-clockwise (as seen from below) to bring the

actuator into the required position.

Actuator without hexagon:

→

Fit special wrench

9)

exactly into the wrench contour on the

underside of the actuator.

→

Rotate clockwise (as seen from below) to bring the actuator into

the required position.

Open-end wrench

with

hexagon

10)

Special wrench

without

hexagon

11)

Fig. 22: Rotating with special key / open-end wrench

9)

The special key (identification number 00 665 702) is available

from your Bürkert sales office.

10)

Series production status since middle of 2011

11)

Series production status up to middle of 2011.

8.4.

Pneumatic connection

DANGER!

Danger – high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

WARNING!

Risk of injury from unsuitable connection hoses!

Hoses which cannot withstand the pressure and temperature range

may result in hazardous situations.

• Use only hoses which are authorized for the indicated pressure

and temperature range.

• Observe the data sheet specifications from the hose manufacturers.

For control function I – Danger if pilot pressure fails!

For control function I control and resetting occur pneumatically.

If the pressure fails, no defined position is reached.

• To ensure a controlled restart, first pressurize the device with

pilot pressure, then switch on the medium.

The pneumatic connection of the angle-seat control valve

can be carried out only in connection with the appropriate

control unit.

Possible control units are:

Positioner Type 8692, 8694 and 8696

Process controller Type 8693

english

Type 2300