Setup & operation, Model bb8000 operational dimensions, Easy setup and operation maximize your uptime – Climax BB8000 PORTABLE LINE BORING MACHINE User Manual

Page 14

There are many ways to set up the Model

BB8000 Boring Machine, depending on the

application and clearances around the work

area. To bore the surface you are mounting on,

standoffs welded on the workpiece give you

clearance for making tool head adjustments.

Insert the boring bar, supported on wooden V-

blocks, in the bore and slip the mounting spider/

bearing plates on each end. Lift the bar to bore

center and attach the mounting spiders to the

workpiece, either internally or externally. Final

centering adjustments are made with the jacking

screws on the bearing plates.

Once the bar is accurately positioned, move

the rotational drive unit into place and lock it to

the bar with two locking collars. Tie-down arms

keep the rotational drive from turning during

boring operations.

Next, place the axial feed unit on either end

of the bar, install the split tool carrier, spacer

blocks and tool head on the bar and you are

ready to make your first boring pass. Actual

boring operations are simply a matter of

adjusting the boring depth at the cutter, setting

the feed rate and direction and starting the

machine rotation.

11/06 3

Setup & Operation

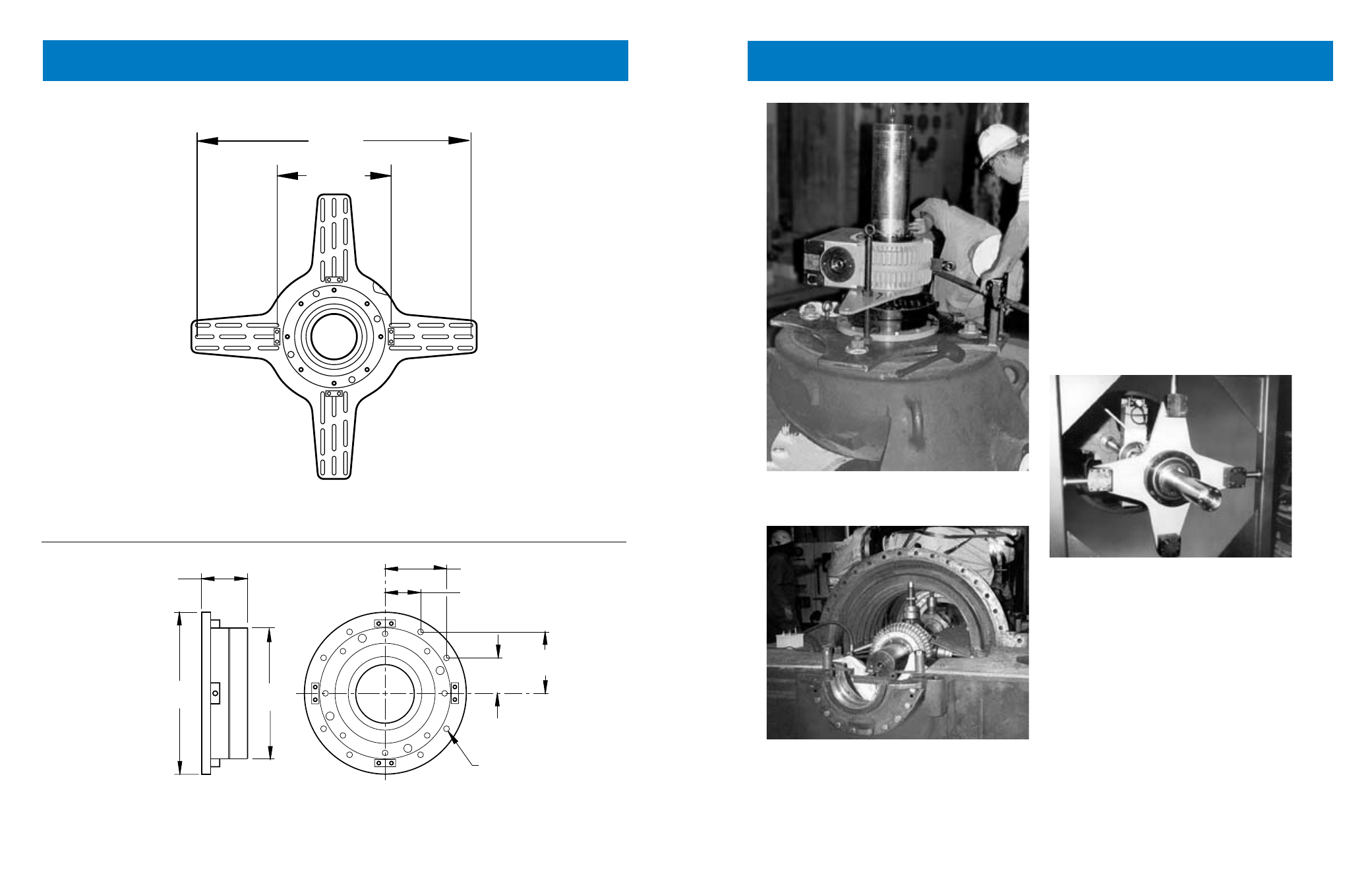

Horizontal setup of the boring bar with ID mounting spiders in a

large turbine. Surface mounts or ID mounts are available.

Vertical mounting of the Model BB8000 Portable Boring

Machine is used to bore a large metropolitan water system

pump.

Easy setup and operation

maximize your uptime.

14 11/06

8" DIAMETER END-MOUNT SELF-ALIGNING

BEARING SUPPORT ASSEMBLY (WITH SPIDER)

.81 (20.6) dia

8 holes

8" SELF-ALIGNING BEARING ASSEMBLY (WITHOUT SPIDER)

4.88 typ

(123.95)

20 min

(508.0)

48 max

(1219.2)

8.44 (214.38) typ

4.88 (123.95) typ

8.44 typ

(214.38)

18.0

(457.2)

22.25

(565.2)

6.67 (169.4)

Model BB8000 Operational Dimensions

Inches (mm)*

* Specifications subject to change without notice.

Individually adjustable clamping feet allow precise

alignment of the ID spider mounting system.