Setup and operation, A fast four-step process – Climax FF5000 FLANGE FACER User Manual

Page 6

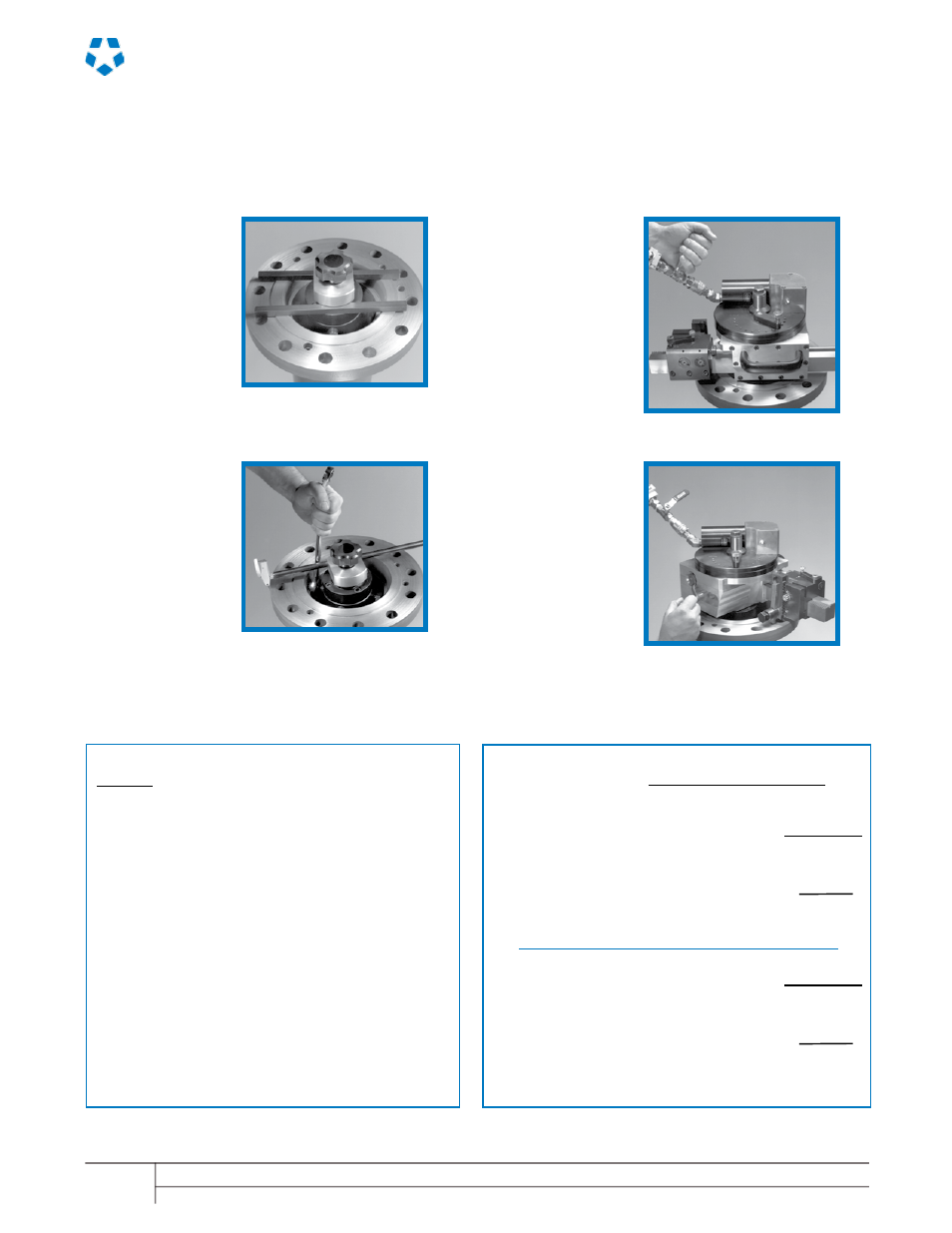

SeTuP anD oPeraTion

a Fast Four-Step Process

Typically, less than 15 minutes for the experienced operator.

1

With the proper

set of jaws

inserted, place

the mounting

chuck into the

flange bore

resting on the

setup bars. Snug

the jaws to hold

the chuck in

place.

2

Use the special

indicator

accessory to

center the chuck

in the bore, then

tighten the jaws

securely. Align

the chuck for

flatness across

the flange by

adjusting the

leveling screws.

3

Attach the

machine body

with one draw

bolt. The machine

may be removed

and replaced

if necessary,

without disturbing

the alignment.

4

Position the tool

head with the

hand crank so the

cutter is at the

desired starting

point. The model

FF5000 Flange

Facer is ready to

run.

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone: 1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 6

Calculating RPM

Calculating Machining Time

12 x SFPM (Surface Feet per Minute)

π x Diameter

1000 x SMPM (Surface Meters per Minute)

π x Diameter

Example 1 (Inch):

12 x 75 SFPM = 3.141 (π) x 13.38 inch dia. x ? (RPM)

900 = 42.03 x ? (RPM)

900 π 42.03 = 21RPM

Example 2 (Metric):

1000 x 23 SMPM = 3.141 (π) x 340 mm dia x ? (RPM)

23000 = 1067.94 x ? (RPM)

23000 π 1067.94 = 21.5 RPM

Length of cut ((OD - ID) / 2)

RPM x Feed

Example (Inch):

Length of Cut:

2.75 inches

Inches / Minute: 0.01 inches

Revolutions / Minute: 21 RPM

Machining Time = 13 minutes / pass

Example (Metric):

Length of Cut:

70 mm

mm / minute:

0.25 mm

Revolutions / minute: 21.5 RPM

Machining Time = 13 minutes / pass

Machining Time =

Machining

Time =

2.75

21 x 0.01

2.75

0.21

Machining

Time =

70

21.5 x 0.25

70

5.375