Tool configurations – Climax FF5000 FLANGE FACER User Manual

Page 4

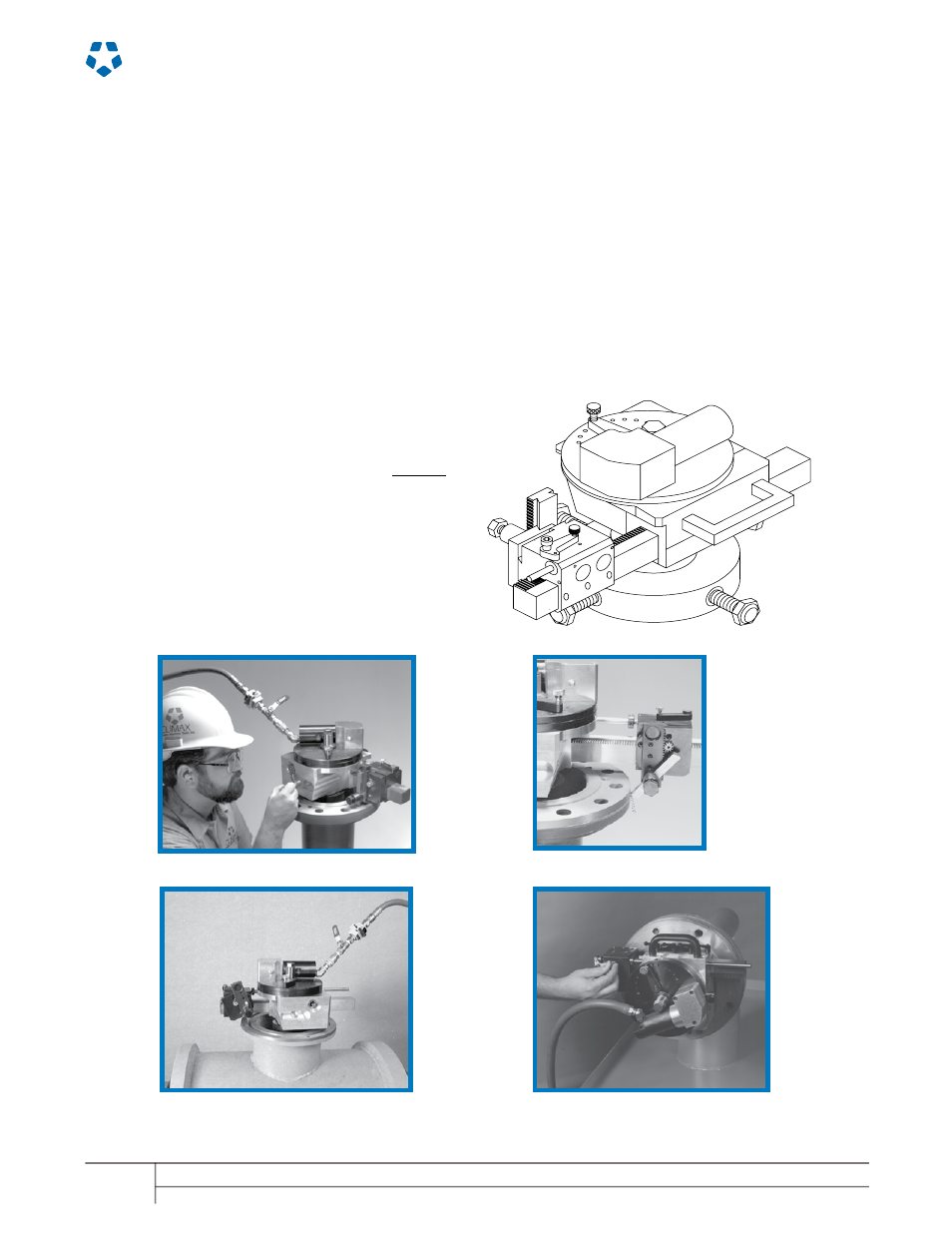

Tool conFiguraTionS

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone:

1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 4

Configure your FF5000 in 3 easy steps.

To configure your FF5000 Flange Facer:

1 Select a Base Unit

2 Select a Drive Option

3 Select a Mounting Option

To configure the Flange Facer you require, simply select the option

you need in each step, then contact your Climax representative.

The base unit includes the base assembly, alignment assembly,

interface assembly, standard compound tool head, a tool kit and

instruction manual.

1 Base Unit

49594

Includes primary machine, alignment assembly,

standard compound tool head, and tool kit

2 Drive Option

34450

Pneumatic motor assembly with air conditioner

3 Mounting Option

5 - 9 inch (127.0 - 228.6 mm) ID mounting chuck

29168

9 - 14 inch (228.6 - 355.6 mm) ID mounting chuck

29167

14 - 18 inch (355.6 - 457.2 mm) ID mounting chuck

29459

More than one mounting chuck may be selected.

By purchasing extra chuck/spindle interface and chuck assmeblies,

you can set up one flange while another is being machined,

significantly reducing downtime in an outage).

Accessories

3.5 - 5 inch (88.9 - 127.0 mm) ID mounting chuck

31627

Chuck spindle interface assembly

29559

Tooling Package

37809

Tool Kit

Tool Bits for Single Point Machining

1/2 x 4.0 inch (12.7 - 102 mm) LH Roughing

31868

1/2 x 4.0 inch (12.7 - 102 mm) LH & RH Finishing

25710

(ground on both ends)

Tools (inch size)

Hex wrench set, 0.050 - 3/8 inch

33999

End wrench, long, 7/8 inch

29173

End wrench, thin, 1-1/8 inch

14668

Crank Handle

29082

Standard configuration

Downfeed on a flange edge

Cutting O-ring and seal groove

Vertical flange facing