Specifications, Test data – Climax LM5200 LINEAR/GANTRY MILL User Manual

Page 2

Climax Portable Machining & Welding Systems Web site: climaxportable.com

Worldwide Phone:

1.503.538.2185 N. America Toll-Free: 1.800.333.8311 Fax: 1.503.538.7600 E-mail: [email protected]

page 2

SpecificationS

All dimensions should be considered reference. Contact your Climax Representative for precision dimensions. Specifications are subject to change without notice. There are no systems or components

on this machine that are capable of producing hazardous EMC, UV or other radiation hazards. The machine does not use lasers nor does it create hazardous materials such as gasses or dust.

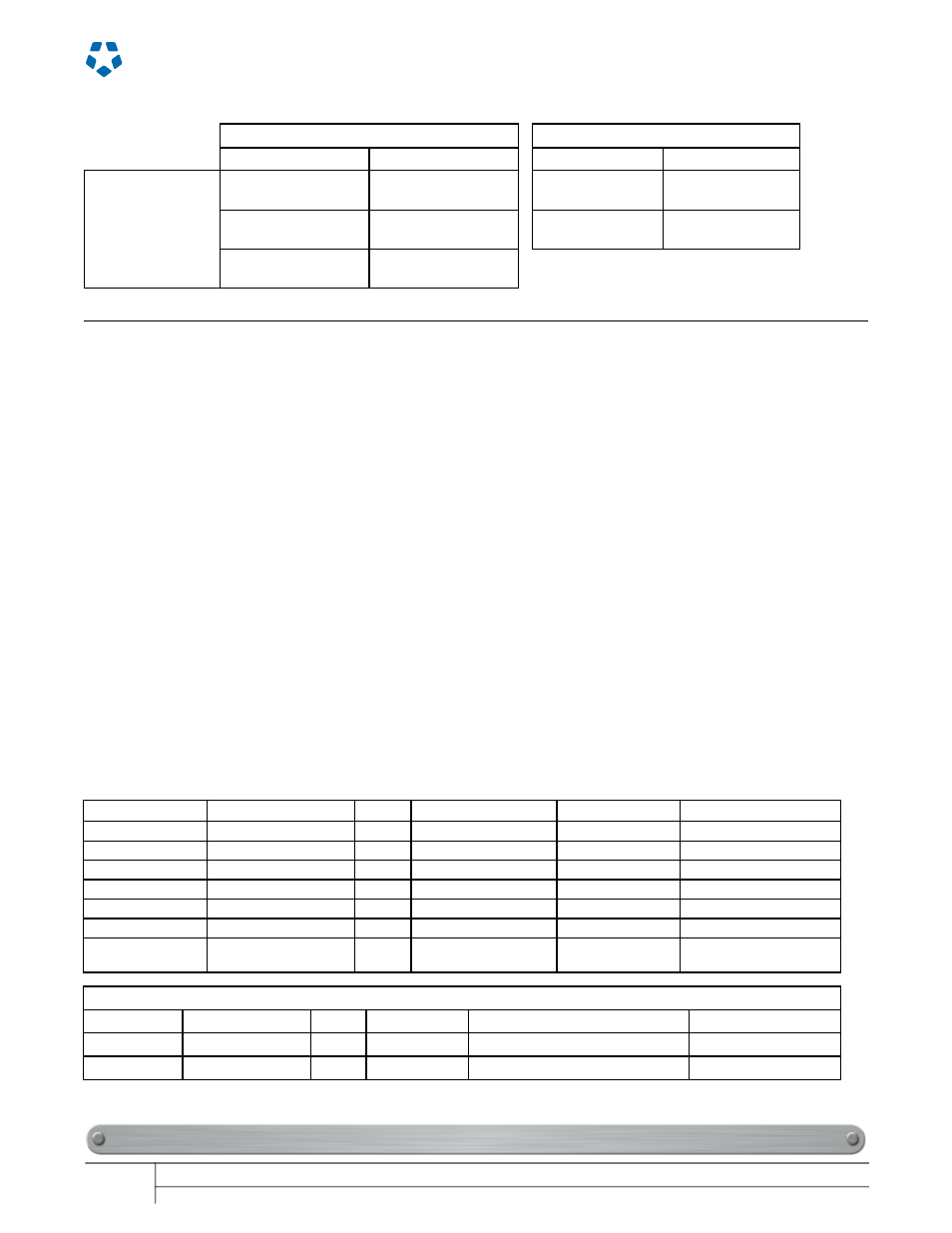

Operating Ranges:

Bed

Ram

Travel

Length

Travel

Length

LM5200 Model

36 inches

(914.4 mm)

48 inches

(1219.2 mm)

16 inches

(406.4 mm)

26 inches

(660.4 mm)

60 inches

(1524.0 mm)

72 inches

(1828.8 mm)

34 inches

(863.6 mm)

44 inches

(1117.6 mm)

84 inches

(2133.6 mm)

96 inches

(2438.4 mm)

US

Metric

Spindle Assembly (Z-Axis):

Milling Head Spindle with #40 Taper

NMTB or CATV or optional HSK

Spindle Drive

Hydraulic, Optional Electric with HSK

Axial Tool Head Travel

4 inches

101.6 mm

Milling Head Gearbox Ratio

1 : 1

1 : 1

Tool Head Position

in 90° increments

(infinite 360° position w/ optional swivel plate)

Gearbox Position Adjustment

180° in 90° increments (3 positions)

Electric Feed

Drive Power

Modified Baldor GP3303 1/2 HP DC gear motor

Gearbox Reduction

20 : 1

Feed Rate

0.5 - 24 in/min

12.7 - 609.6 mm/min

Power Input Requirements

0.37 kW @ 120V or 230V

Overall Dimensions

Bed (overall length)

Bed Length + 2.5 in.

Bed Length + 63.5 mm

Ram (overall width)

Ram Length + 2.5 in.

Ram Length + 63.5 mm

Height without hand wheel

18.75 inches

476.3 mm

with hand wheel

22.0 inches

558.8 mm

TEST DATA

All test cuts performed with a 10Hp (7.5 KW) HPU and a 7.3 cu. in. (119.6 cu. cm) hydraulic motor in A-36 steel

Orientation

Cutter Diameter

Inserts Depth of Cut

Width of Cut

Feed Rate

Horizontal Overhang

6 inches (152.4 mm)

7

0.020 inches (0.508 mm)

6 inches (152.4 mm)

14 in/min (355.6 mm/min)

Horizontal Overhang

6 inches (152.4 mm)

7

0.020 inches (0.508 mm)

3 inches (76.2 mm)

14 in/min (355.6 mm/min)

Horizontal Gantry

6 inches (152.4 mm)

7

0.020 inches (0.508 mm)

3 inches (76.2 mm)

12 in/min (304.8 mm/min)

Horizontal Gantry

6 inches (152.4 mm)

7

0.055 inches (1.397 mm)

3 inches (76.2 mm)

1 in/min (25.4 mm/min)

Vertical

4 inches (101.6 mm)

6

0.020 inches (0.508 mm)

3 inches (76.2 mm)

15 in/min (381 mm/min)

Drilling

1.5 inch (38.1 mm) superdrill

n/a

2 inches (50.8 mm)

n/a

Spindle RPM: 250

Boring

2.5 inch (63.5 mm)

Criterion Boring Head

n/a

2 inches (50.8 mm)

n/a

Spindle RPM: 425

Flatness (Machine setup & flatness measurements performed with a Hamar laser)

Configuration

Cutter Diameter

Inserts

Material

Area

Total Flatness

Linear Milling

6 inches (152.4 mm)

7

A-36 Steel Plate

6.0 x 36.0 inches (152.4 x 914.4 mm)

0.0018 inches (0.046 mm)

Gantry Milling

6 inches (152.4 mm)

7

A-36 Steel Plate

6.0 x 36.0 inches (152.4 x 914.4 mm)

0.0015 inches (0.038 mm)