36v prolynx, 5a: non-isolated dc-dc power modules, Data sheet – GE Industrial Solutions 9-36V ProLynx 5A User Manual

Page 14: Module

GE

Data Sheet

9-36V ProLynx

TM

5A: Non-Isolated DC-DC Power Modules

9Vdc –36Vdc input; 3Vdc to 18Vdc output; 5A to 2.5A Scaled output current

9Vdc –24Vdc input; -3.3Vdc to -18Vdc output; 5A to 0.7A Scaled output current

July 23, 2013

©2012 General Electric Company. All rights reserved.

Page 14

Tunable Loop

TM

The 9-36V ProLynx

TM

modules have a new feature that

optimizes transient response of the module called Tunable

Loop

TM

.

External capacitors are usually added to the output of the

module for two reasons: to reduce output ripple and noise (see

Figs 30 and 31) and to reduce output voltage deviations from

the steady-state value in the presence of dynamic load current

changes. Adding external capacitance however affects the

voltage control loop of the module, typically causing the loop

to slow down with sluggish response. Larger values of external

capacitance could also cause the module to become unstable.

The Tunable Loop

TM

allows the user to externally adjust the

voltage control loop to match the filter network connected to

the output of the module. The Tunable Loop

TM

is implemented

by connecting a series R-C between the SENSE and TRIM pins

of the module, as shown in Fig. 38. This R-C allows the user to

externally adjust the voltage loop feedback compensation of

the module.

Recommended values of R

TUNE

and C

TUNE

for different output

capacitor combinations are given in Tables 2, 3 and 4. Tables 2

and 3 show recommended values of R

TUNE

and C

TUNE

for

different values of ceramic output capacitors up to 100

μ

F that

might be needed for an application to meet output ripple and

noise requirements. Selecting R

TUNE

and C

TUNE

according to

Tables 2 and 3 will ensure stable operation of the module

In applications with tight output voltage limits in the presence

of dynamic current loading, additional output capacitance will

be required. Table 4 lists recommended values of R

TUNE

and

C

TUNE

in order to meet 2% output voltage deviation limits for

some common output voltages in the presence of a 50% of full

load step change with an input voltage of 12 or 28V.

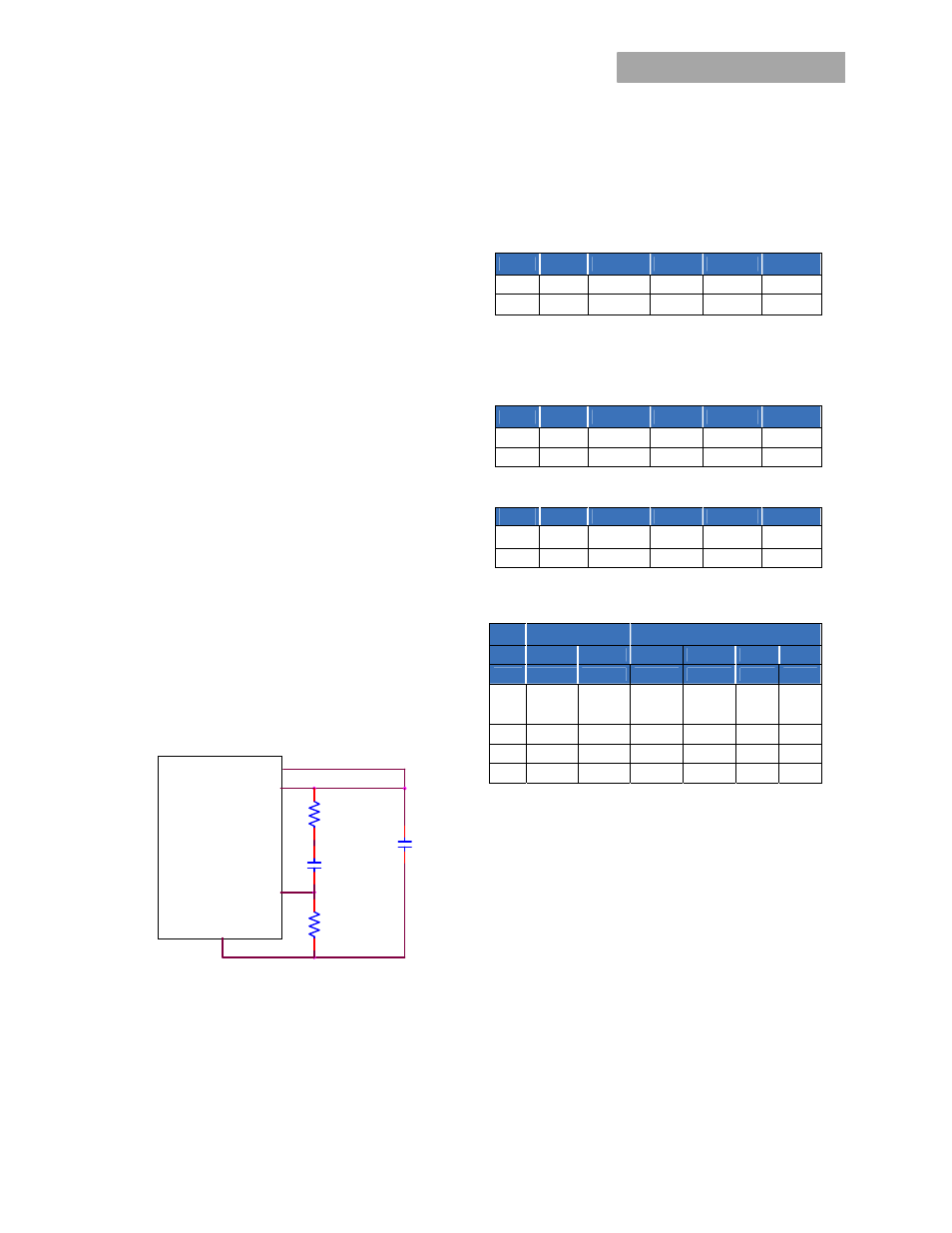

Figure. 38. Circuit diagram showing connection of R

TUME

and

C

TUNE

to tune the control loop of the module

.

Please contact your GE technical representative to obtain more

details of this feature as well as for guidelines on how to select

the right value of external R-C to tune the module for best

transient performance and stable operation for other output

capacitance values or input voltages other than 12 / 28V.

Table 2. General recommended values of of R

TUNE

and C

TUNE

for Vin=12V and various external ceramic capacitor

combinations.

Vo=5V

Co

1x10

μF

1x22

μF

2x22

μF

4x22

μF

6x22

μF

R

TUNE

330 270 270 220 180

C

TUNE

680pF 1200pF 2700pF 4700pF 5600pF

Table 3. General recommended values of of R

TUNE

and C

TUNE

for Vin=28V and various external ceramic capacitor

combinations.

Vo=5V

Co

1x10

μF

1x22

μF

2x22

μF

4x22

μF

6x22

μF

R

TUNE

330 220 220 150 150

C

TUNE

220pF 390pF 680pF 1000pF 1800pF

Vo=12V

Co

1x10

μF

1x22

μF

2x22

μF

4x22

μF

6x22

μF

R

TUNE

330 330 270 270 180

C

TUNE

120pF 470pF 1000pF 1800pF 2700pF

Table 4. Recommended values of R

TUNE

and C

TUNE

to obtain

transient deviation of 2% of Vout for a 50% of full load step.

Vin

12V

28V

Vo

3.3V

5V

3.3V

5V

12V

18V

∆I

2.5A

2.35A

2.5A

2.35A

1.75A

1.5A

Co 1x330μF

OsCon

1x330

μF

OsCon

1x330

μF

OsCon

1x330

μF

OsCon 2x22μF 1x22μF

R

TUNE

180 180 180 220 270

330

C

TUNE

22nF 22nF 6800pF

6.8nF

470pF

47pF

ΔV

39mV 37mV 36mV 34mV

220mV 310mV

MODULE

VOUT

SENSE

TRIM

GND

RTUNE

CTUNE

RTrim

C O