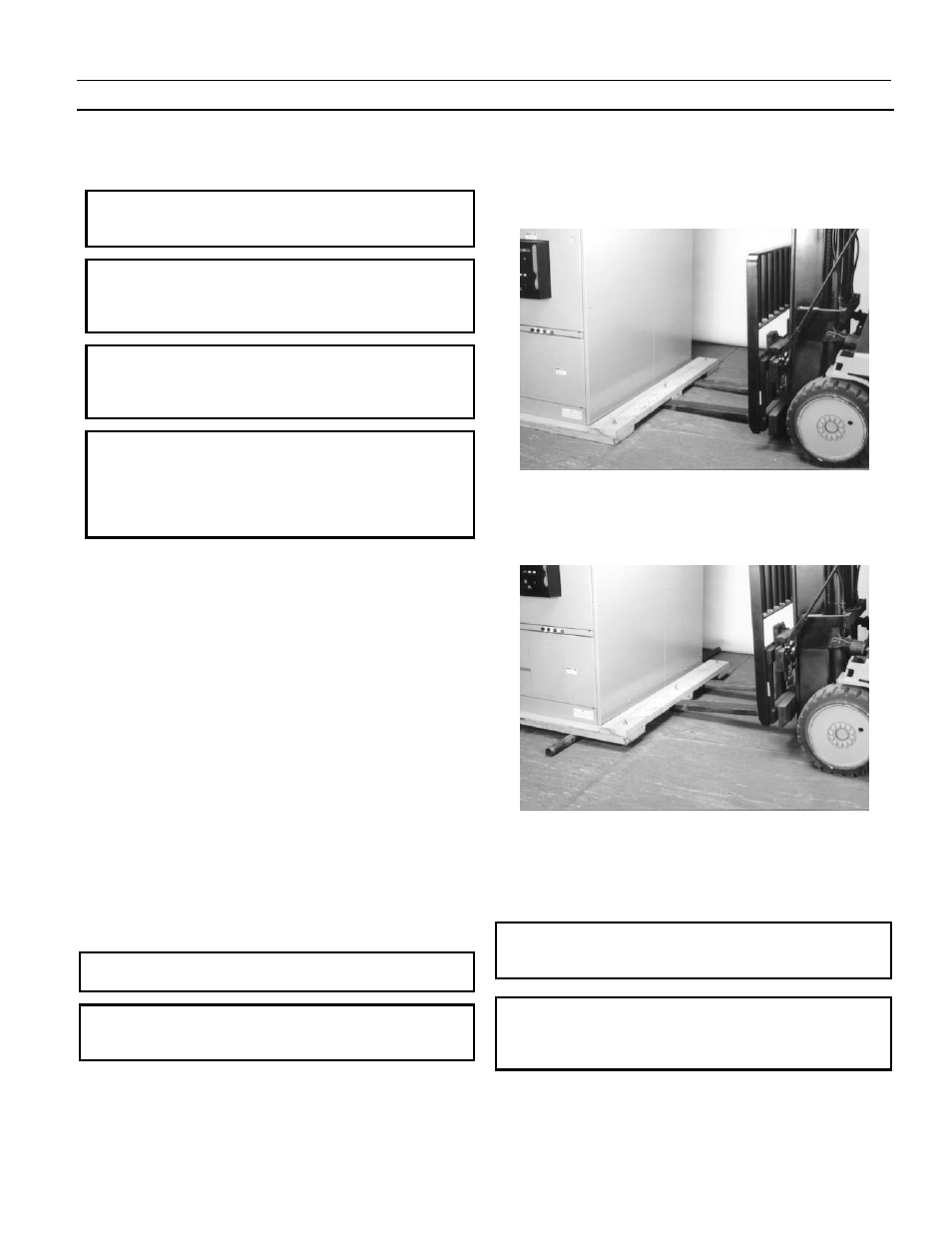

Rollers, Forklifts, Fig. 2-5. placement of rollers under shipping skid – GE Industrial Solutions Entellisys Installation User Manual

Page 11

5

Entellisys Low Voltage Switchgear

Chapter 2. Receiving, Handling, and Storage

Take up the slack in the lifting device very carefully and

manually stabilize the switchgear to prevent it from rotating.

WARNING: Do not stand under switchgear while it is

being moved. Serious injury may occur if the cables or

lifting device fail.

AVERTISSEMENT: Ne vous tenez pas sous le dispositif

de commutation lorsqu’il est bougé. Des blessures graves

peuvent survenir si les câbles ou l’appareil de levage

tombent en panne.

CAUTION: Gently lower the switchgear section onto the

level site location. If the switchgear is roughly handled or

jarred, it is possible to damage or misalign internal

components.

ATTENTION: Abaisser doucement la section du

dispositif de commutation sur l’endroit d’installation

nivelé. Une détérioration ou un désenlignement des

composantes internes sont possibles si le dispositif de

commutation est manipulé grossièrement ou soumis à des

vibrations.

Rollers

If crane facilities are not available, the equipment may be

moved into position by means of construction rollers placed

under the shipping skids. The switchgear may be raised

enough for the placement of rollers by means of a forklift or

jack.

There should never be less than four rollers under the

equipment unless the line-up is less than five feet long. Use

one roller for each 18 inches of equipment length.

Forklifts

When using a forklift to raise the line-up to position rollers

underneath, proceed as follows:

1.

Expand forklift tines to their maximum (widest)

extension.

2.

Carefully insert tines of forklift below one side of the

switchgear line-up at the approximate center of the

panel as shown in Fig. 2-4.

NOTE: Do not attempt to lift or move the equipment with

a forklift positioned in the front or rear of the equipment.

NOTE: Ne pas essayer de lever ou bouger cette pièce

d’équipement à l’aide d’un chariot élévateur placé à l’avant

ou à l’amère de celle-ci.

3.

Raise equipment and position one roller under the skids

close to the raised end of the line-up.

4.

Carefully lower the gear until it rests on the roller as

shown in Fig. 2-5.

5.

Repeat the lifting process at the other end and place the

appropriate number of rollers under the skids spacing

them evenly across the width of the line-up.

Fig. 2-4. Placing forklift tines under Entellisys

equipment shipping skid

Fig. 2-5. Placement of rollers under shipping skid

6.

Carefully lower the gear until it rests on the rollers

(Fig. 2-6).

NOTE: If shipping skids are removed prior to final

placement of equipment, rollers may only be used to move

the equipment in a direction parallel to the front.

NOTE: Si l’emballage d’expédition a été enlevé avant que

l’équipement ne soit rendu à son emplacement final,

l’utilisation de rouleaux pour bouger l’équipement n’est

permise qu’en direction parallèle à l’avant.