Conclusions – GE P&W FuelSolv - Slag Control Treatment Program at EKPC Spurlock Station User Manual

Page 8

Page 8

Technical Paper

Impact of Slagging and Fouling Index

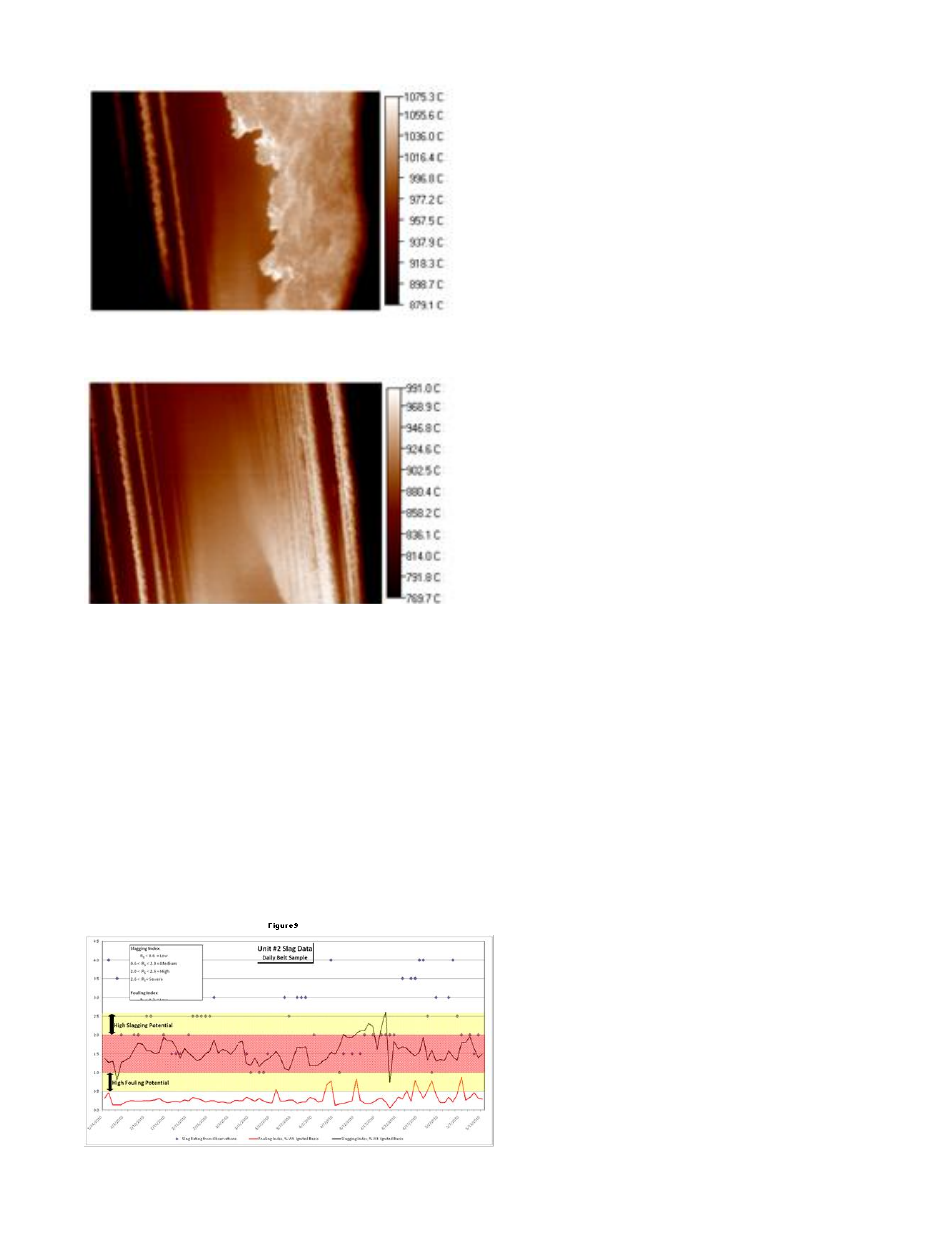

The fouling index of coal burned in Unit 2 increased

significantly. EKPC Spurlock found a different type of

buildup during the May 2010 Air Heater repair out-

age. A lighter weight fouling deposit was seen as

opposed to the heavy slag typically seen. Slagging

or fouling that did form came off tubes easier with

sootblowing. Figure 9 shows coal slagging and foul-

ing index plotted against slag rating.

We saw Unit 2 slag rating increase due to deteriora-

tion of burner tips over time.

Fuel Cost Savings

As many as eight different Illinois Basin coal

sources were used to fuel Units 1 and 2 in 2010.

Coal-A was the lowest cost, but the coal with the

highest slagging tendencies. In the past Spurlock

Station was unable to continuously burn Coal-A.

Burning alternate fuels came at an incremental

cost per ton. Coal-A comprised 22% of all coal

burned in 2010. Relative costs of all fuels are

shown in Table 10. Minimum savings associated

with the ability to burn Coal-A are shown in Table

11 while maximum savings are shown in Table 12.

Replacing Coal-A with 100% Coal-B is not practi-

cal and so the total Fuel Cost savings are realisti-

cally between $2,413,000 and $7,600,000.

Total operating cost for the FuelSolv FMG2960

program is estimated at $2,172,000.

Conclusions

The FuelSolv FMG2960 program was successful

when applied directly to a coal belt and combined

with targeted sootblowing practices. Application

of FMG2960 slag control chemistry with consistent

boiler operating practices produced the following

results:

Eliminated clinkers on Unit 1 SH Platens and

eliminated damaging slag falls

Reduced pluggage on Unit 2 RH. Slag that

formed was brittle and easily removed with air

sootblowers

The majority of slag that developed shed at

shutdown, eliminating much of the cost of off-

line high pressure water blasting

Slag that did form broke up very easily, signifi-

cantly reducing problems with grinding hard

bottom ash

FMG2960 enabled EKPC Spurlock to regularly

burn high slagging coals without pluggage or

large slag falls

Enabled EKPC Spurlock to burn high slagging

coals that they were not able to burn in the

past

Reduced overall fuel costs by as much as

$7,000,000 per year

Unit 2 RH from Right Wall at IK #10 after De-rate 7-4-10

Unit 2 RH from Right Wall at IK #10 7-2-10