GE P&W Pleated Filters - XPleat PES Pleated Filters User Manual

Xpleat* filters, Typical applications, General properties

Fact Sheet

XPleat* Filters

Pleated Filters with Polyethersulfone (PES) Membrane

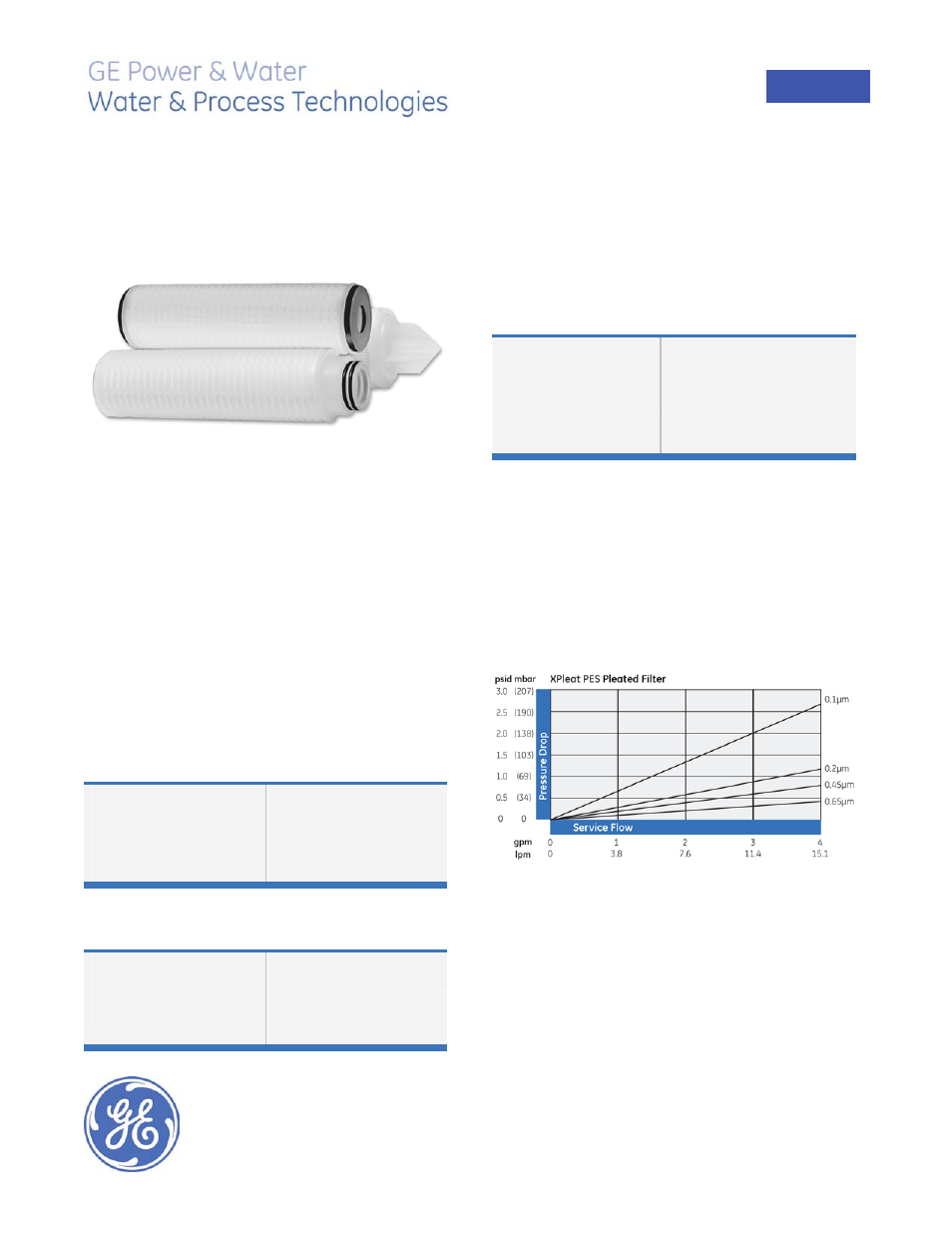

Figure 1: Xpleat PES Filters

Typical Applications

• For general water services

• For fine process fluid filtration

• For processes that require excellent flow rates

General Properties

Xpleat* filters are available the following absolute

pore size micron ratings: 0.1, 0.2, 0.45 and 0.65 µm.

Tables 1, 2, 3 and 4 show further details on materi-

als of construction, dimensions, operational limits

and flow performance.

Table 1: Materials of Construction

Filter Media

Polyethersulfone Membrane

Media Support

Polypropylene Microfiber

Components

Polypropylene

Sealing

Thermal Bonding

O-Rings/Gaskets

Silicone, Buna, Viton

1

, EPDM

1

Viton is a trademark of DuPont

Table 2: Dimensions

Outside Diameter

2.75” (70 mm)

Inside Diameter

1.25” (31 mm)

Effective Filtration Area

8.1ft

2

(0.75m

2

)

Lengths

10, 20, 30, 40 inches

(25.4, 50.8, 76.2, 101 cm)

Table 3: Operational Limits

Maximum Forward

Differential Pressure

60 psi (4.14 bar)

Maximum Reverse

Differential Pressure

30 psi (2.07 bar)

Maximum Operating

Temperature

180ºF (82ºC) at 10 psid (0.69 bar)

in water

Chemical Compatibility

GE filter cartridges are designed and manufactured

for resistance to a wide range of chemical solutions.

Conditions will vary with each application and users

should carefully verify chemical compatibility.

Please contact your GE distributor for more infor-

mation.

Table 4: Flow Performance in Clean Water

1

1

Data based on 10” length filter

Additional Information

GE certifies that the materials contained within the

XPleat PES filters meet U.S. FDA requirements for

food contact under the applicable regulations in

21CFR. XPleat PES filters meet the test criteria for

USP Class VI-121C Plastics.