GE P&W Spiral Wound Membranes - Certified Elements User Manual

Certified elements, Nsf 61 certified drinking water ro and nf elements, Fact sheet

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1266EN.doc Sep-13

Certified Elements

NSF 61 Certified Drinking Water RO and NF Elements

The National Sanitation Foundation (NSF) provides

conformity assessment services in the area of public

health for the food preparation and plumbing water

industries. NSF is an organization accredited by the

American National Standard Institute (ANSI) to certify

products against several NSF/ANSI Standards, includ-

ing NSF Standard 61. NSF/ANSI Standard 61 is a test-

ing protocol that assures customers and regulators

that

products

do

not

contribute

to

unsafe levels of contaminants in drinking water.

AG and AK certified elements are selected when in-

comparable confidence is requested from drinking

water system components.

AG and AK certified elements feature a fiberglass out-

er wrap and standard feed spacers.

Table 1: Element Specification

Membrane

Thin-Film Membrane (TFM*)

AG Series - RO High Rejection Elements

Model

Average

permeate flow

gpd (m3/day)

1,2

Average NaCl

rejection

1,2

Minimum NaCl

rejection

1,2

AG4040FM CERT

2,200 (8.3)

99.5 %

99.0 %

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 2,000ppm NaCl solution at 225psi (1,551kPa) operating pres-

sure, 77 °F, pH 7.5 and 15% recovery.

AK Series - RO Low Energy Elements

Model

Average

permeate flow

gpd (m3/day)

1,2

Average NaCl

rejection

1,2

Minimum NaCl

rejection

1,2

AK4040FM CERT

2,200 (8.3)

99.0 %

98.0 %

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 500ppm NaCl solution at 115 psi (790kPa) operating pressure,

77 °F, pH 7.5 and 15% recovery.

Model

Active area

ft

2

(m

2

)

Outer wrap

Part

number

AG4040FM CERT

85 (7.9)

Fiberglass

1231652

AK4040FM CERT

85 (7.9)

Fiberglass

1231655

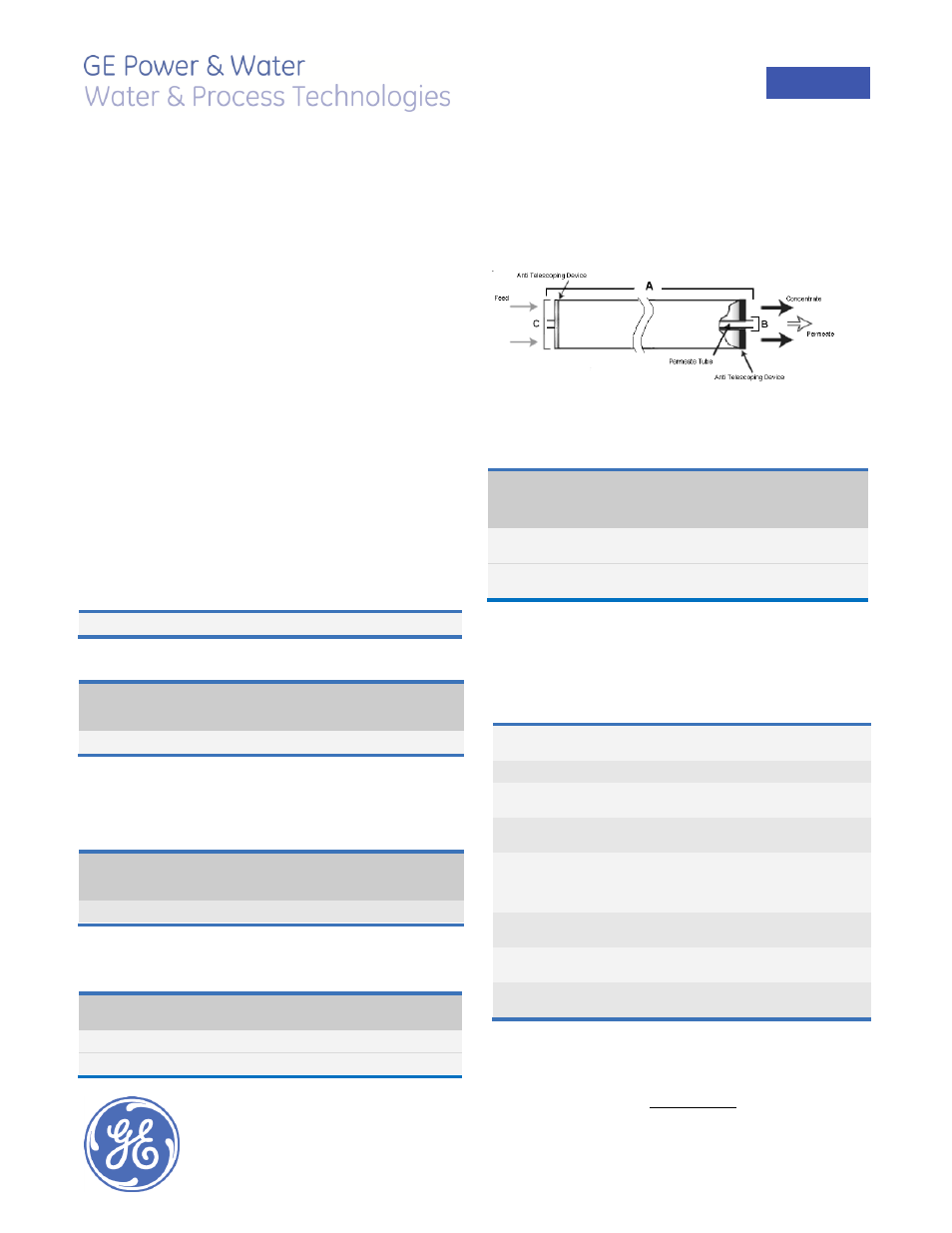

Figure 1: Element Dimensions Diagram – Male

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

AG4040FM CERT

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9)

8

(3.5)

AK4040FM CERT

40.0

(101.6)

0.75

(1.90) OD

3.9

(9.9)

8

(3.5)

1

These elements are bagged dried before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in GE

Water & Process Technologies pressure vessels. Other pressure vessel dimension

and tolerance may result in excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

Typical Operating Pressure

AG Series: 200 psi (1,379 kPa)

AK Series: 100 psi (689 kPa)

Typical Operating Flux

10-20GFD (15-35LMH)

Maximum Operating Pressure

AG Serie: 600 psi (4,137 kPa),

AK Serie: 400 psi (3,758 kPa)

Maximum Temperature

All: Continuous operation: 122°F (50°C)

AG-AK Series Clean-In-Place (CIP): 122°F (50°C)

pH Range

AG-AK Series:

Optimum rejection pH: 7.0-7.5

Continuous operation: 4.0-11.0

Clean-In-Place (CIP): 2.0-11.5

Maximum Pressure Drop

Over an element: 12psi (83kPa)

Per housing: 50psi (345kPa)

Chlorine Tolerance

1,000+ ppm-hours,

dechlorination recommended

Feedwater

NTU < 1

SDI < 5