GE P&W FuelSolv - Slag Control Treatment Program at EKPC Spurlock Station User Manual

Page 6

Page 6

Technical Paper

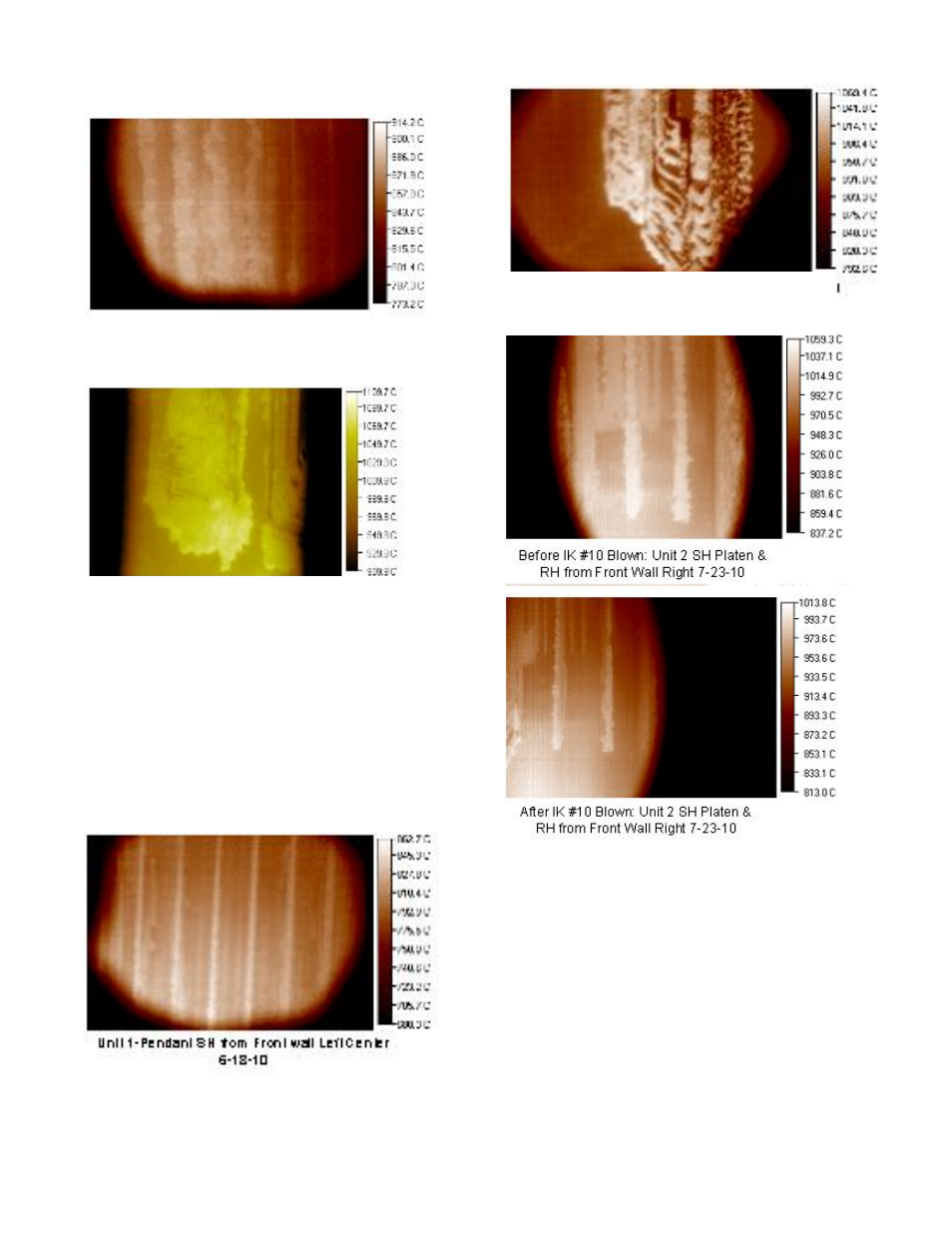

Heavy slag buildup on SH Pendants and bottom

edge of SH Platens. Slag falls from Platens caused

damage to lower furnace tubes.

No Slag buildup on SH Pendants. No Clinkers on bot-

tom edge of SH Platens. No slag falls from Platens.

Unit 2 experienced similar results. The FuelSolv

FMG2960 treatment program did not eliminate slag

buildup; however, slag that did develop was more

friable and easier to remove with sootblowing.

Outages

Unit 2 experienced three outages in March, May

and October 2010, following the start of the Fuel-

Solv FMG2960 treatment program.

In the March outage, clean gas paths between RH

assemblies were observed. Little slag was seen on

the bottom of the SH Pendants. The slag that was

present was a very brittle and friable deposit that

shed easily as the unit came down and cooled.

Some wall clinkers that did not shed as the unit

cooled were present. The largest wall clinker at

the Left Front Wall trouble spot was removed with

a shotgun in about an hour. Compared to the pre-

Unt 1- Pendant SH from Front wall Right

3-26-10

Unt 1- Pendant SH from Front wall Left

3-26-10

Unit 1-100% Illinois Basin Coal-No Treatment

Unt 1- Bottom of Rear SH Platen from Front wall at

Center Right 6-18-10