Treatment application, Boiler performance, Tools – GE P&W FuelSolv - Slag Control Treatment Program at EKPC Spurlock Station User Manual

Page 3

Technical Paper

Page 3

Treatment Application

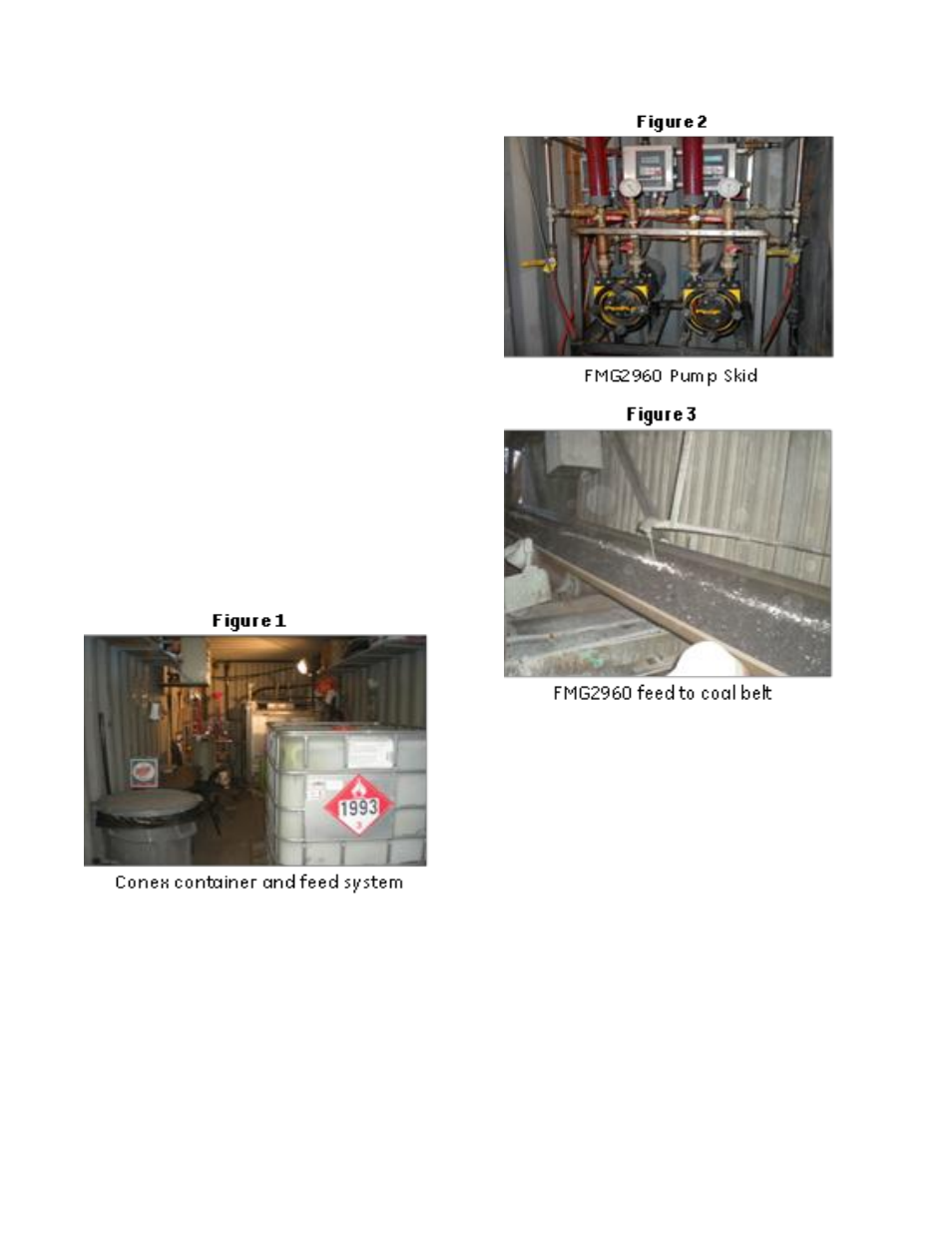

Fuelsolv FMG2960 was applied directly to the coal at

the Unit 1 and 2 Crusher House. The target dosage

was 75 ml of FMG2960 per ton of coal treated. See

Figure 3.

FMG2960 feed was automated to two belts, PC1A

and PC1B. Typically PC1A feeds Unit 1 while PC1B

feeds Unit 2, however either belt can feed either

unit. Chemical feed was automated using a 4-20 mA

signal from each belt scale, with coal-on-belt and

belt running permissive signals. An ACTech Variable

Frequency Drive (VFD) and Periflo peristaltic chemi-

cal metering pump were dedicated to each belt. The

Fuelsolv FMG2960 was delivered to the plant in 240-

gallon totes and transferred using a high volume

transfer pump.

A temporary feed system, for the purpose of con-

ducting an evaluation of the FuelSolv FMG2960 slag

control technology was relatively simple to install

once all of the feed system components were on

site. The feed system for Spurlock station was in-

stalled and operational in about 3 weeks’ time. (See

Figure 1 and Figure 2)

Boiler Performance

The objective of the FuelSolv FMG2960 slag control

program was to minimize the impact of slagging

while burning a high percentage of lowest cost, high

sulfur, high slagging index coal. The intent was to

burn 100% of Coal-A during an initial evaluation,

when possible. Success of the program would be

determined by the following criteria:

Hard slag formation across Pendant RH on

Unit 2

Clinker formation on bottom of Pendant SH on

Unit 2

Large clinker formation on Platen SH sections

on Unit 1

Damaging slag falls on both units

Unscheduled down time due to slag falls

Unscheduled down time for off-line cleaning

Derates due to uncontrolled slag formation

Tools

A number of different tools were used to docu-

ment the conditions in the boilers treated with the

FuelSolv FMG2960. These included:

FMG2960 Application Rate

Visual Inspections

Slag Ratings