GE P&W FuelSolv - Slag Control Treatment Program at EKPC Spurlock Station User Manual

Page 4

Page 4

Technical Paper

Digital Infrared Photography

Digital Videography

Off-line inspections with standard digital pho-

tography

Daily Coal Belt Samples

The FMG2960 Application Rate was monitored dai-

ly. Actual product usage was compared to coal ton-

nage since last reading to calculate milliliters of

FMG2960 per ton of coal and compared to the tar-

get rate of 75 ml/ton. Application rate monitoring

provides alerts to potential feed system problems

and helps ensure a consistent product application

rate over time. Figure 4 shows typical application

rate over time. The addition of a 4-20 mA signal

from each coal belt improved overall application

rate control.

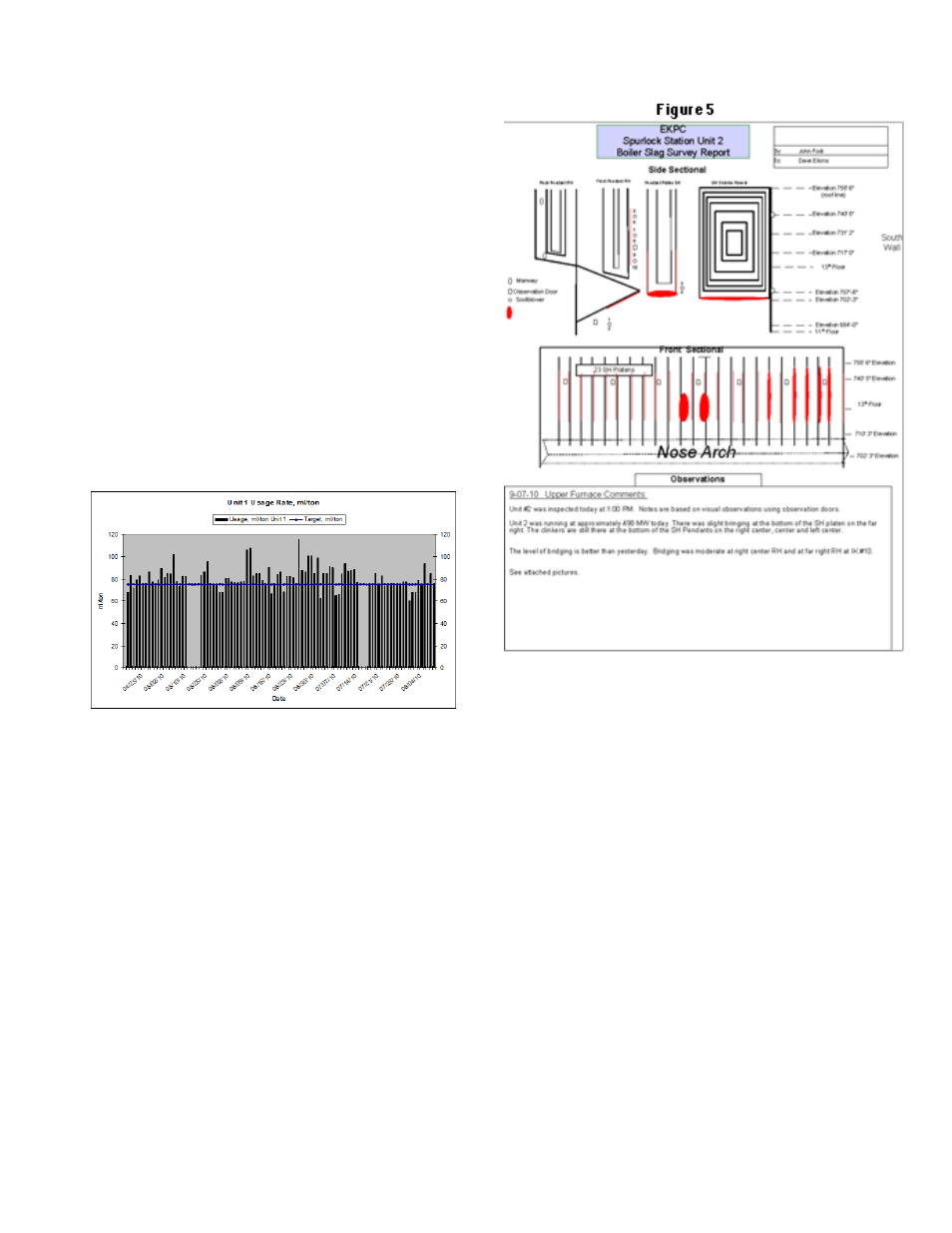

Visual Inspections were conducted on a daily basis

and recorded in a Visio template with Digital IR

Photography. The inspections establish a point in

time record and form the basis for daily slag ratings.

Figures 5 and 6 represent examples of the inspec-

tion document format.

Slag Ratings were developed in order to convert

information from visual observations into empirical

data. The data can then be used to trend perfor-

mance of the slag control program when compared

to coal quality or other boiler operating conditions.

The slag rating used is on a scale from 0 to 5 with

boiler specific criteria for each level. A slag rating of

0 represents very little slag formation while a rating

of 5 represents severe slag conditions.

Digital Videography was used routinely to record

conditions and observe the impact of periodic

events such as soot blowing. A standard digital

video camera in an air-cooled enclosure was typi-

cally used to record slag buildup between RH as-

semblies from either sidewall observation port on

the Unit 2 CE boiler, in 15-30 second video clips.

Off-line inspections documented with digital pho-

tography were conducted following every planned

and unplanned outage. Inspections were con-

ducted at the earliest possible time following boil-

er cool down. This is the best time to examine the

fireside of the boiler for clinkers. It is also a good

time to assess the ability for existing slag to shed

as the boiler cools down and the friability of any

remaining slag

Figure 4

Figure 5

Figure 5

Figure 5

Figure 5

Figure 5

Figure 5

Figure 5

Figure 5