Results summary – GE P&W FuelSolv - Slag Control Treatment Program at EKPC Spurlock Station User Manual

Page 5

Technical Paper

Page 5

Daily Coal Samples were conducted to provide a

reference to coal and ash quality through the early

stages of the FMG2960 evaluation. The intention

was to compare coal quality to observed slagging

conditions in the treated boilers.

Results Summary

Unit 1 and 2 began evaluations of the FMG 2960 at

different points in 2010. Unit 2 began its slag con-

trol evaluation on January 29

th

, while Unit 1 began

its slag control evaluation on April 19

th

. The plan

with Unit 2 was to run 3 of 5 silos with 100% Coal-A

throughout the evaluation period. The plan with Unit

1 was to run 100% Coal-A during its evaluation pe-

riod. In the past, Spurlock Station was unable to run

either boiler with this fuel diet. In both cases, base-

line information from visual observations was estab-

lished.

Slag Ratings-Unit 1 operated at high slag ratings for

the period of approximately 3 months leading to the

start of the FMG2960 evaluation. Slag buildup in

trouble spots on Unit 1 decreased significantly as

indicated by the visual observations and the result-

ant slag ratings.

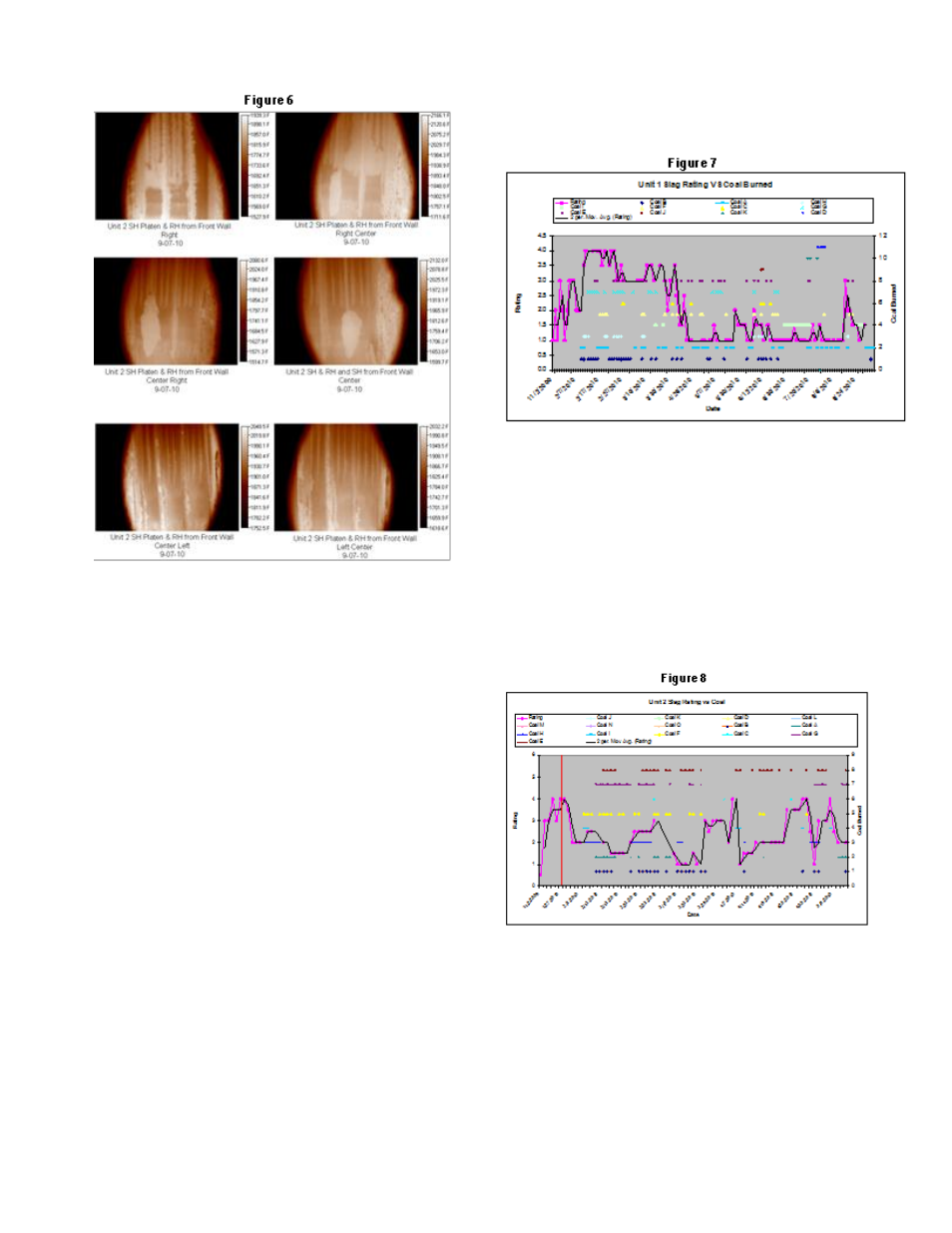

Figure 7 shows Unit 1 slag rating over time versus

coal burned. Coal-A and Coal-F are the highest

slagging index coals. Overall slag control improved

significantly with the addition of the FMG2960 slag

control program.

Unit 2 operated at very good levels of slag control

throughout the evaluation period. The feed of the

highest slagging index coal began following the

start of the FMG2960 slag control treatment pro-

gram.

The evaluation period on Unit 2 began on

1/29/2010 and ended on 5/9/2010. Throughout

this period plant operations experienced no ob-

served clinker formation on Planten SH and were

able to consistently control slag buildup at the hot

spot on the right side of the Front Pendant RH.

Unit 2 slag control was most effective when soot-

blowers IK#5 through IK#10 were deployed every

3 to 4 hours. However compressed air capacity

was a limiting factor at times, restricting soot-

blower availability.

Infrared Digital Photo- The ability to control slag

was evident when comparing observed conditions

prior to and during treatment with the FuelSolv

FMG2960 additive.