GE P&W FuelSolv - Slag Control Treatment Program at EKPC Spurlock Station User Manual

Page 7

Technical Paper

Page 7

vious clinker in the same location, the clinker was

more brittle and easier to remove. The previous

clinker had to be high-pressure water blasted.

Likewise in the May outage, most existing clinkers

shed as the unit came down and cooled. The largest

wall clinker at the Left Front Wall trouble spot was

removed with a shotgun in about 10 minutes. Com-

pared to the previous clinker in the same location,

the clinker was more brittle and easier to remove.

The previous clinker took about an hour to remove.

No off-line, high-pressure water blasting was re-

quired.

In the Unit 2 October outage, some slag was ob-

served at the bottom of the RH at the bullnose near

the right corner. Mostly clear gas paths were ob-

served between RH assemblies. The large clinker at

the Left Front Wall trouble spot would not break up

with a shotgun but shed as the boiler temperature

dropped overnight. Small clinkers present at the

bottom of SH Platens were easily removed with a

shotgun. Aside from some small clinkers, furnace

walls appeared very clean.

Impact of Load Drop

Unit 2 experienced 18 days at the highest slag rat-

ing due to bridging on right RH & inability to remove

with sootblowing. Under these circumstances Unit 2

was dispatched to a reduced load causing slag to

shed. No noise or damage was caused by the ther-

mal de-slag.

Through some periods during the FuelSolv FMG2960

treatment program, the ability to soot-blow was lim-

ited. This was primarily due to limitations of the

plants compressed air system. It was not always

possible to soot blow the areas where slag buildup

occurred at the frequency that was required.

Burning the same coal blend in 2009,

Slag developed over 80% of RH

ID Fan Inlet pressure equaled –33 inches

Furnace pressure at +9.6 inches (Unit trips at

+10 inches)

Furnace pressure went positive and everything

behind the RH went very negative.

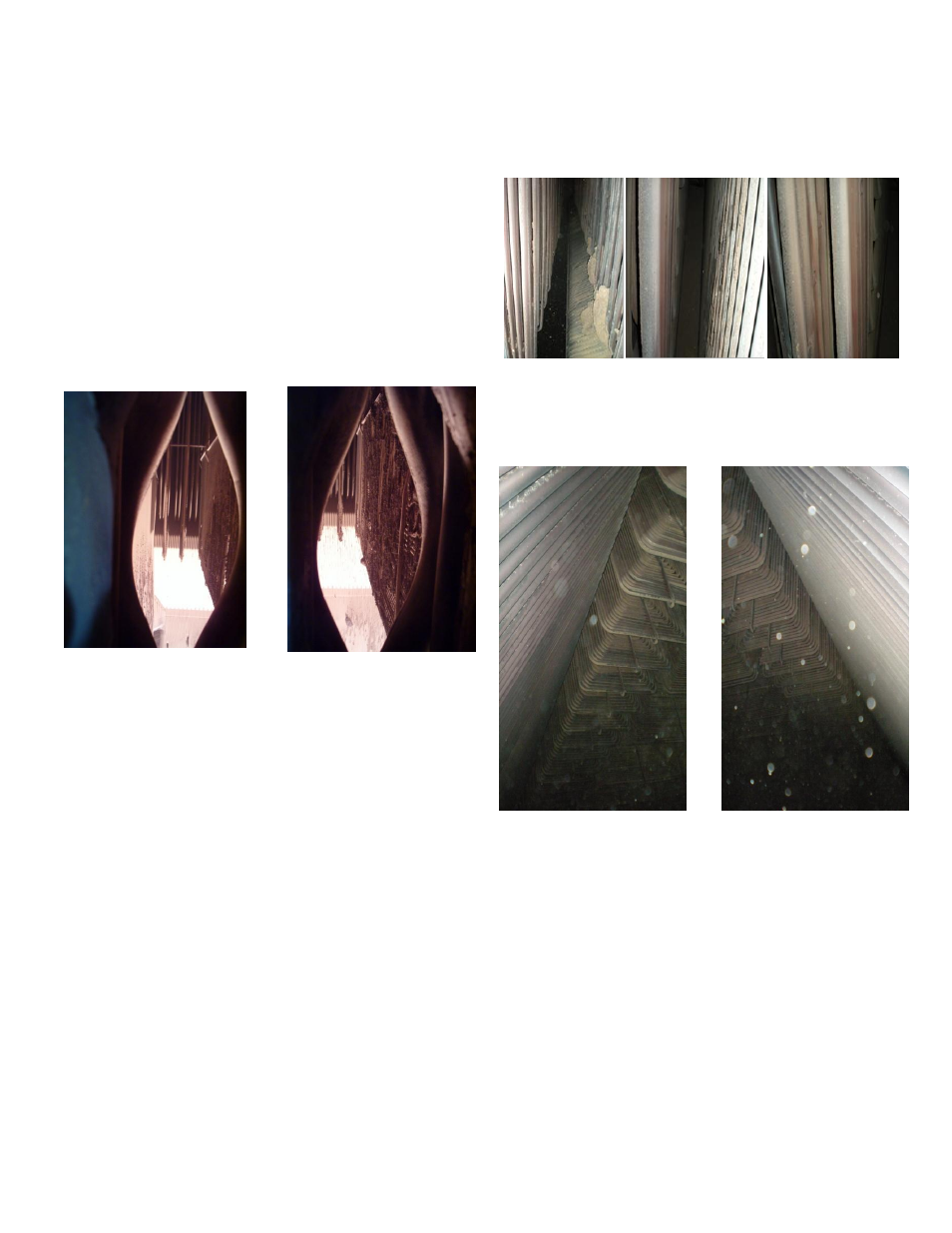

Unit 2-March 5

th

Outage

Unit 2-October 12th Outage

Lower Bullnose and SH

Assemblies from IK#1

Lower Bullnose and SH

Assemblies from IK#2

SH Pendant,

Bullnose and RH

from IK #10

RH Gas Lane Right Wall

from IK #10