GE P&W Mobile Water Treatment Systems - MobileFlow User Manual

Mobileflow, Description and use, Typical applications

Fact Sheet

Find a contact near you by visiting www.ge.com/water and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2009, General Electric Company. All rights reserved.

FS1057EN.doc Apr-09

MobileFlow*

Description and Use

GE offers the world’s largest fleet of mobile water

treatment systems, providing demineralization,

filtration, softening, and deoxygenation treatment,

quickly and efficiently – available for either emer-

gency, supplemental, or extended term service.

All aspects of treatment, from system analysis and

design through installation, maintenance, up-

grades and emergency response are available.

Included are immediate system backup, complete

analytical laboratory, application and engineering

consultants, qualified Field Service Representa-

tives (FSR’s), regional service centers, and a 24-

hour dispatch and control center.

Each MobileFlow* system contains six rubber-

lined ASME code steel tanks of uniform size, with a

patented piping system to allow operation in se-

ries or parallel. The system can be operated by

FSR’s, your plant personnel or remotely monitored.

Automatic shutdown features protect from power

failure, excess pressure and off-specification wa-

ter. Regional service centers perform regenera-

tion quality control checks on every unit.

Demineralization treatment is available in as little

as two hours plus transit time. Other special ap-

plications may require additional time.

Typical Applications

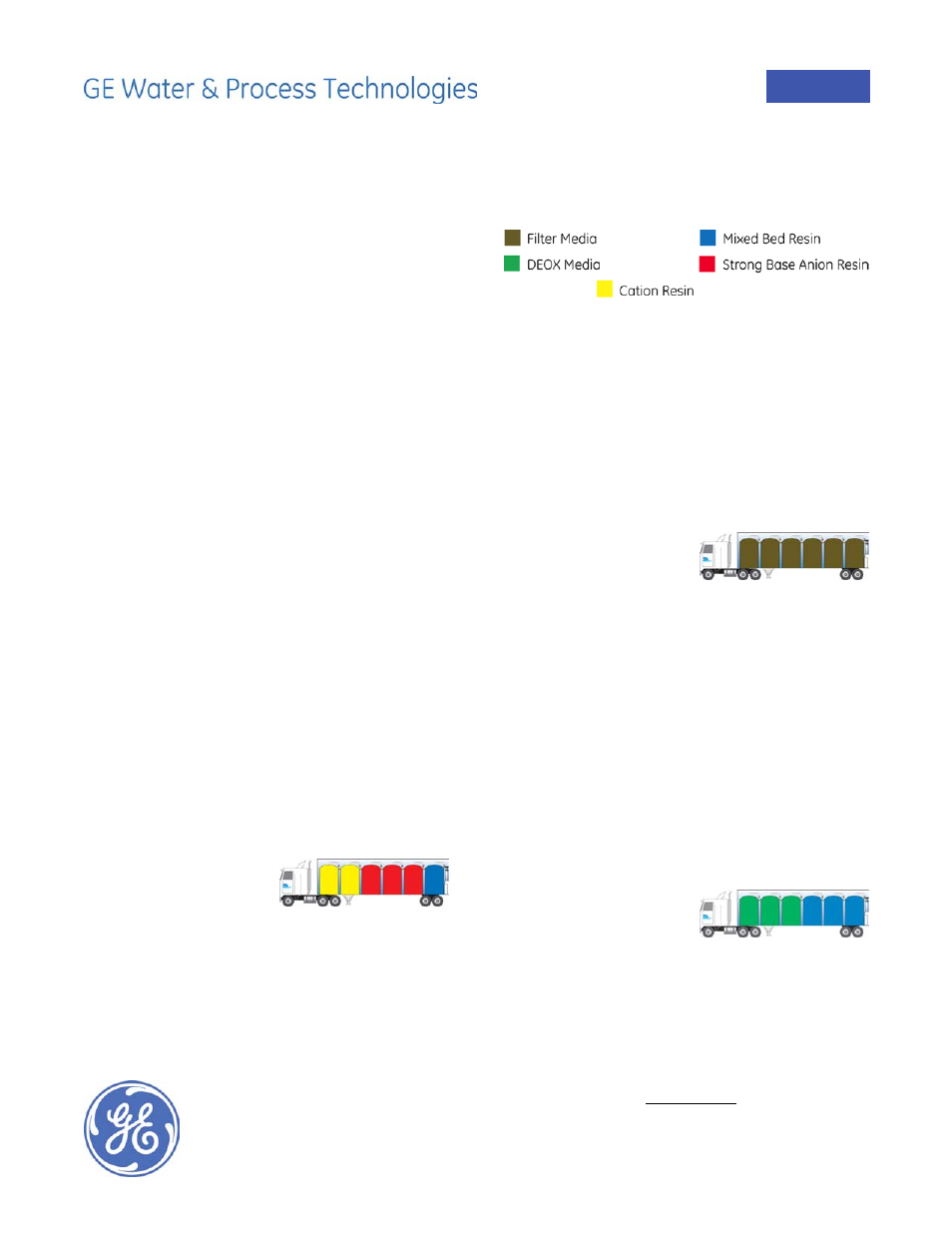

Demineralization

Premium 10% cross-linked cation resins and po-

rous Type I strong base anion resins are standard

in custom loading of the MobileFlow system.

Regeneration of ion exchange resins at service

centers provides the highest conversions for eco-

nomical production of ultra pure water. A proprie-

tary rinse is used on the selected resins to prevent

any residual QC test water from remaining in the

trailer when it is delivered to the user. Off-site

resin regeneration gives the customer the use of a

true zero discharge system.

Formalized resin purchase specifications include

specific test procedures and quality limits to en-

sure that the products are free of manufacturing

impurities, and can meet the most stringent speci-

fications.

Filtration

GE stands alone in filtration capability, having pio-

neered in-line coagulation for the mobile water

treatment industry. The MobileFlow system takes

advantage of a proprietary dual media filter that is

treated with a biocide, acid, and hot water after

each use to protect against cross-contamination

from various surface water sources.

We guarantee the effluent quality for influents up

to 50 NTU and the system can also treat water up

to 100 NTU. Treatment flow rates are dependent

upon the influent turbidity values. Typically, flow

rates up to 600 GPM per trailer are possible with

influent values of less than 10 NTU.

Deoxygenation

Our patented DEOX* process provides a water

quality of less than 1 ppb dissolved oxygen, with

0.5 ppb typically measured. Clients in the pulp and

paper, petrochemical, refinery, and utility

industries have benefited by our capability to

Document Outline

- MobileFlow*

- Description and Use

- Typical Applications

- Our patented DEOX* process provides a water quality of less than 1 ppb dissolved oxygen, with 0.5 ppb typically measured. Clients in the pulp and paper, petrochemical, refinery, and utility industries have benefited by our capability to deoxygenate water

- Utilizing a cation/mixed bed configuration, condensate can be polished to remove crud loading and trace ionic contaminants during unit start-ups or for longer-term requirements. The 10% cross-linked cation resin is strong enough to withstand aggressive

- General Properties

- Further Information