GE P&W Spiral Wound Membranes - OSMO BEV NF Series User Manual

Osmo* bev nf series, Beverage and bottled water production, Fact sheet

Fact Sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1277EN.doc Nov-13

OSMO* BEV NF Series

Beverage and Bottled Water Production

The OSMO* BEV NF membrane element is engi-

neered to provide beverage plants with consistent,

high quality water for production of carbonated soft

drinks, juices, and sport drinks. The OSMO BEV NF

element will process most municipal or plant well-

water to meet your alkalinity, hardness and low so-

dium requirements. The OSMO BEV NF membrane

element is chlorine tolerant, and offers a salt pas-

sage profile that permits maximum water recovery

by the NF.

The OSMO BEV NF membrane element is tested and

certified by NSF International against NSF/ANSI

Standard 61 for material requirements only.

Features include a Full-Fit* design that eliminates

the stagnant zone associated with industrial FRP

elements and their brine seals, which can act as a

site for bacterial growth. The OSMO BEV NF element

forms a flush-fit with the inner diameter of the

membrane element housing, creating a self-

cleaning effect. This design also offers less pressure

resistance than an industrial FRP element, resulting

in lower brake horsepower and substantial energy

savings.

The OSMO BEV NF membrane is following a 100%

Wet Test Quality Assurance.

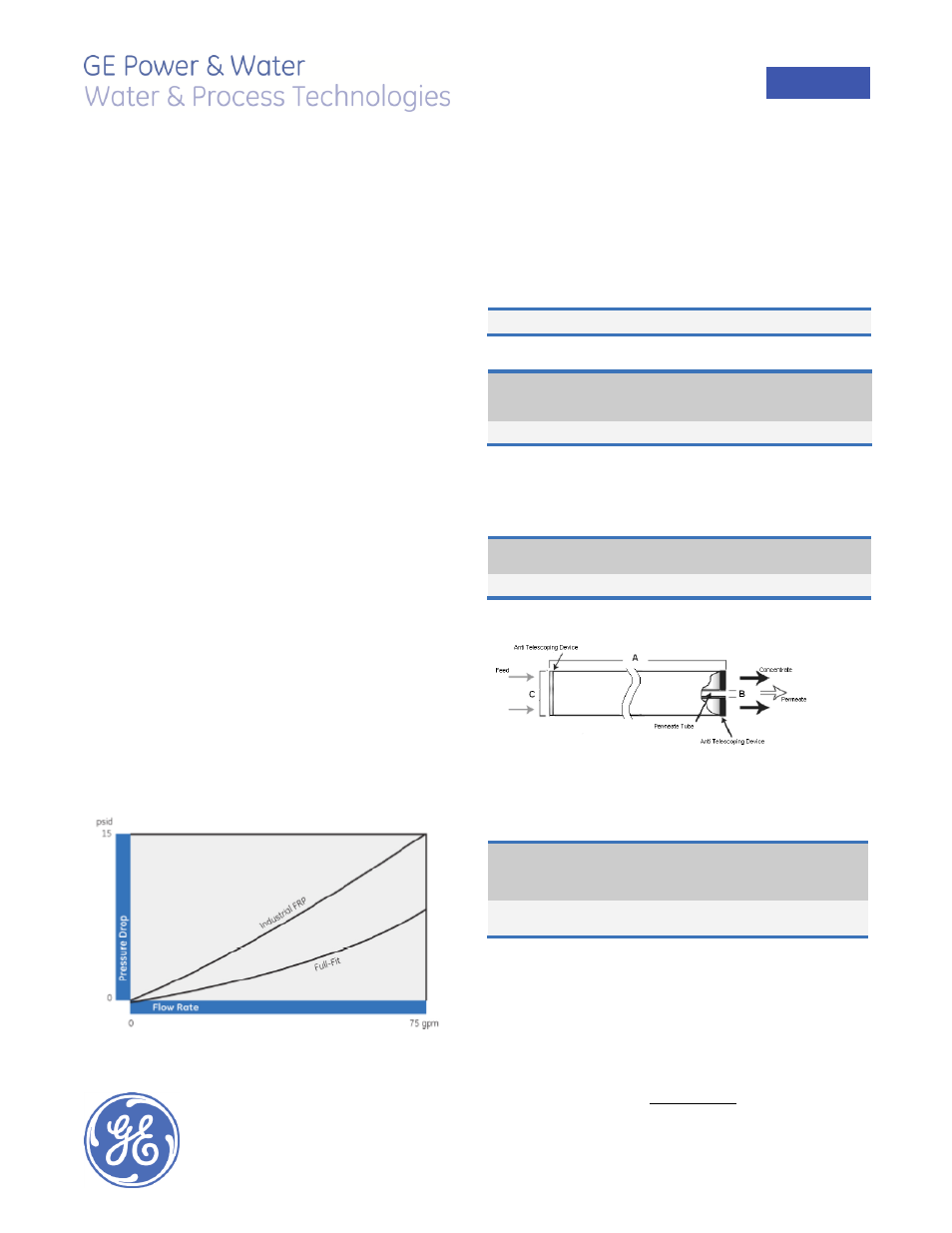

Figure 1: High Flow Rate at Low Pressure Drop.

Table 1: Element Specification

Membrane

Cellulose Acetate

Model

Average

permeate flow

gpd (m

3

/day)

1,2

Average MgSO

4

rejection

1,2

Average NaCl

rejection

1

OSMO-BEV-NF-FF

8,200 (31.0)

97.0%

60%

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-15%.

2

Testing conditions: 2,000ppm MgSO

4

solution at 225psi (1,551kPa) operating

pressure, 77 °F, pH 6.5 and 15% recovery.

Model

Active area

ft

2

(m

2

)

Outer wrap

Part

number

OSMO-BEV-NF-FF

336 (31.2)

Full-Fit*

1233033

Figure 1: Element Dimensions Diagram – Female

Table 2: Dimensions and Weight

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

OSMO-BEV-NF-FF

40.0

(101.6)

1.125

(2.86)

7.9

(20.1)

32

(14.5)

1

These elements are dried then bagged before shipping.

2

Internal diameter unless specified OD (outside diameter).

3

The element diameter (dimension C) is designed for optimum performance in GE

Water & Process Technologies pressure vessels. Others pressure vessel dimension

and tolerance may result in excessive bypass and loss of capacity.