Max6948b, Table 14. recommended inductors, Applications information – Rainbow Electronics MAX6948B User Manual

Page 25

High-Efficiency PWM LED Driver with Boost

Converter and Five Constant-Current GPIO Ports

25

MAX6948B

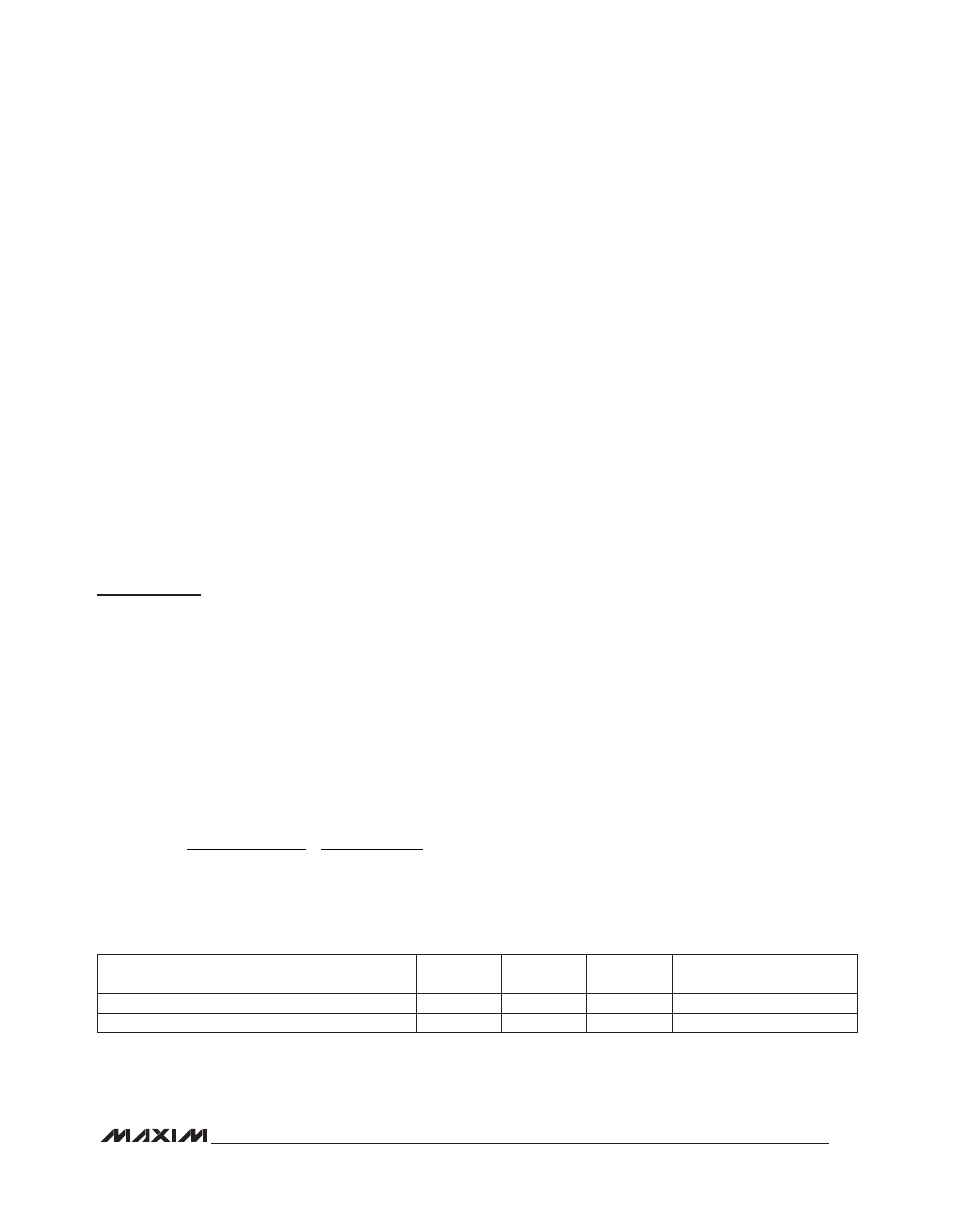

Table 14. Recommended Inductors

Operation with Multiple Masters

When the MAX6948B is operated on a 2-wire interface

with multiple masters, a master reading the MAX6948B

uses a repeated start between the write that sets the

MAX6948B’s address pointer, and the read(s) that takes

the data from the location(s). This is because it is pos-

sible for master 2 to take over the bus after master 1 has

set up the MAX6948B’s address pointer but before mas-

ter 1 has read the data. If master 2 subsequently resets

the MAX6948B’s address pointer, master 1’s read can

be from an unexpected location.

Command Address Autoincrementing

Address autoincrementing allows the MAX6948B to be

configured with fewer transmissions by minimizing the

number of times the command address needs to be

sent. The command address stored in the MAX6948B

generally increments after each data byte is written or

read (Table 1). Autoincrement only works when doing a

burst read or write.

Applications Information

Inductor Selection

The MAX6948B is optimized for a 10FH inductor,

although larger or smaller inductors can be used. Using

a smaller inductor results in discontinuous-current-mode

operation over a larger range of output power, whereas

use of a larger inductor results in continuous conduction

for most of the operating range.

To prevent core saturation, ensure that the inductor’s

saturation current rating exceeds the peak inductor cur-

rent for the application. For larger inductor values and

continuous conduction operation, calculate the worst-

case peak inductor current with the following formula:

OUT

OUT(MAX)

IN(MIN)

PEAK

IN(MAX)

V

I

V

0.5 s

I

0.9 V

2 L

Ч

Ч

µ

=

+

Ч

Ч

Otherwise, for small values of L in discontinuous conduc-

tion operation, I

PEAK

is 860mA (typ). Table 14 provides a

list of recommended inductors.

Capacitor Selection

The typical input capacitor value is 2.2FF and the typical

output capacitor is 0.22FF. Higher value capacitors can

reduce input and output ripple, but at the expense of size

and higher cost. For best operation, use ceramic X5R or

X7R dielectric capacitors. Generally, ceramic capacitors

with smaller case sizes have poorer DC bias character-

istics than larger case sizes for a certain capacitance

value. Select the capacitor that yields the best trade-off

between case size and DC bias characteristics.

Diode Selection

The high switching frequency of the MAX6948B demands

a high-speed rectification diode for optimum efficiency.

A Schottky diode is recommended due to its fast recov-

ery time and low forward-voltage drop. Ensure that the

diode’s average and peak current rating exceeds the

average output current and peak inductor current. In

addition, the diode’s reverse-breakdown voltage must

exceed V

OUT

.

Compensation Network Selection

The step-up converter uses an external compensation

network from COMP to GND to ensure stability. For 5 or 6

WLEDs, choose C

COMP

= C

OUT

/10 for optimal transient

response.

Port Input and I

2

C Interface Logic Voltages

The MAX6948B I

2

C supply (V

DD

) accepts voltages

from 1.7V up to the boost-converter input (V+). V

DD

determines the I

2

C interface (SDA, SCL), I

2

C slave-

address select input (AD0), and reset input (RST) logic

voltages. The five I/O ports P0–P4 are overvoltage pro-

tected to 5.5V independent of V

DD

or V+. This allows the

MAX6948B to operate from one supply voltage, such as

3.3V, while driving some of the five I/Os as inputs from a

different logic level, such as 5V.

VENDOR PART NUMBER

L

(µH)

DCR

(mω)

I

SAT

(A)

CASE SIZE

(mm)

TOKO 1069AS-220M

22

570

0.47

3 x 3 x 1.8

TOKO 1098AS-100M

10

290

0.75

2.8 x 3 x 1.2