Capacities and specifications, General product information, 12" series ii sweep 16" series ii sweep – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-720-G2 User Manual

Page 19

4. General Product Information

PNEG-720-G2 12" and 16" Series II Sweep

19

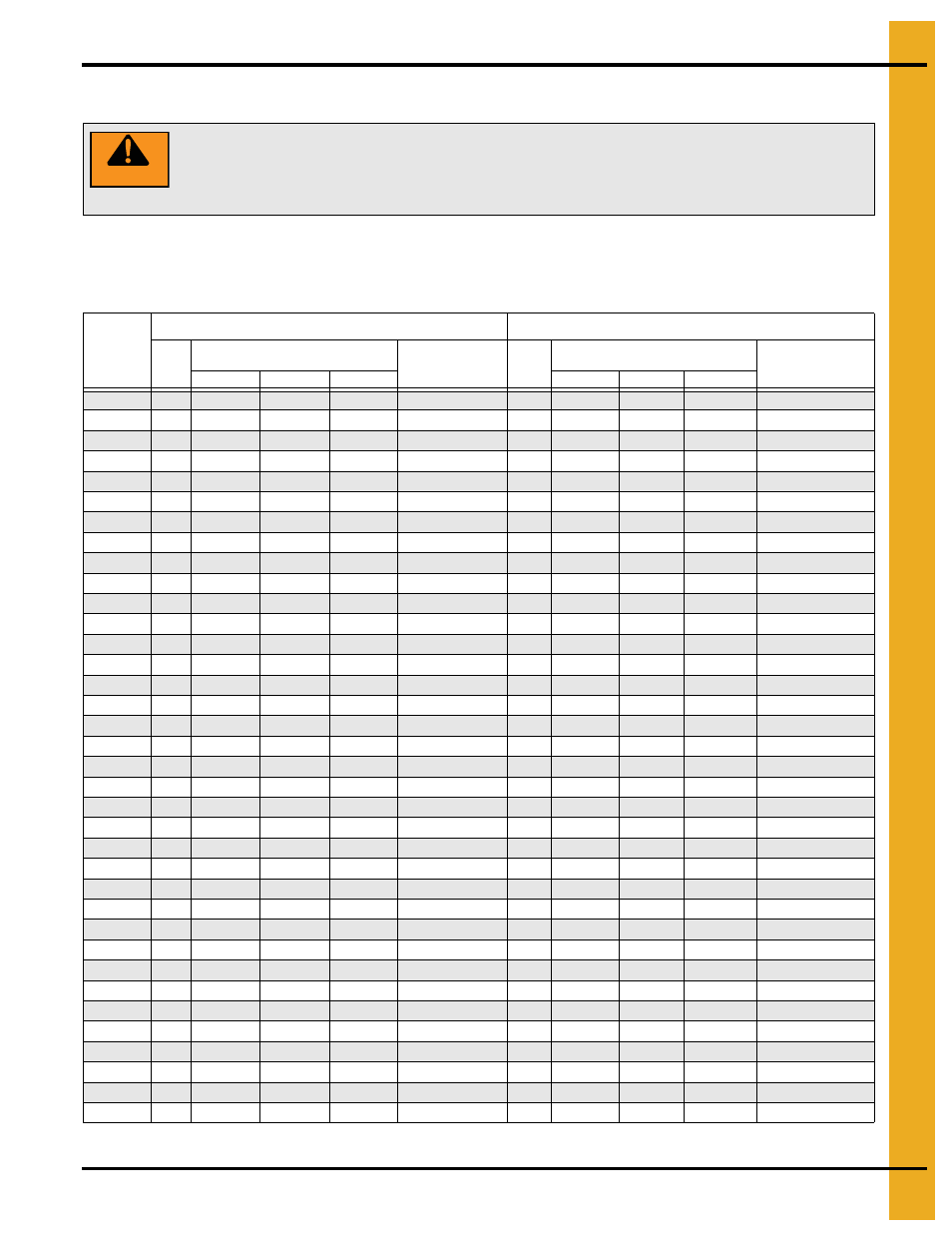

Capacities and Specifications

A. Use the

to determine the horsepower required.

NOTE: Sweep is not designed to start under full load.

Due to continual improvements, GSI designs and specifications are subject to change without notice.

Bin

Diameter

12" Series II Sweep

16" Series II Sweep

Drive

HP

Bushel/MT per Hour

Horsepower

Length

Pivot to End

Drive

HP

Bushel/MT per Hour

Horsepower

Length

Pivot to End

5000/125

6000/155

7000/180

8000/205

9000/230

10000/255

36'

2

7.5

7.5

7.5

16.79' (5.12 m)

2

7.5

7.5

7.5

16.85' (5.14 m)

37'

2

7.5

7.5

7.5

17.79' (5.43 m)

2

7.5

7.5

7.5

16.85' (5.14 m)

39'

2

7.5

7.5

7.5

18.79' (5.73 m)

2

7.5

7.5

7.5

17.85' (5.44 m)

40'

2

7.5

7.5

7.5

18.79' (5.73 m)

2

7.5

7.5

7.5

18.75' (5.72 m)

42'

2

7.5

7.5

7.5

19.79' (6.04 m)

2

7.5

7.5

10

19.85' (6.05 m)

43'

2

7.5

7.5

7.5

20.79' (6.34 m)

2

7.5

7.5

10

19.85' (6.05 m)

45'

2

7.5

7.5

7.5

20.79' (6.34 m)

2

7.5

7.5

10

20.85' (6.36 m)

48'

2

7.5

7.5

7.5

22.79' (6.95 m)

2

7.5

10

10

22.85' (6.96 m)

49'

2

7.5

7.5

7.5

22.79' (6.95 m)

2

7.5

10

10

22.85' (6.96 m)

51'

2

7.5

7.5

10

23.79' (7.26 m)

2

7.5

10

10

23.85' (7.27 m)

54'

2

7.5

7.5

10

25.79' (7.86 m)

2

10

10

10

25.85' (7.88 m)

55'

2

7.5

7.5

10

25.79' (7.86 m)

2

10

10

10

25.85' (7.88 m)

57'

2

7.5

7.5

10

26.79' (8.17 m)

2

10

10

10

26.85' (8.18 m)

59'

2

7.5

7.5

10

27.79' (8.47 m)

2

10

10

15

27.85' (8.49 m)

60'

2

7.5

7.5

10

28.79' (8.78 m)

2

10

10

15

28.85' (8.79 m)

62'

2

7.5

7.5

10

29.79' (9.08 m)

2

10

10

15

29.85' (9.10 m)

63'

2

7.5

7.5

10

29.79' (9.08 m)

2

10

10

15

29.85' (9.10 m)

66'

2

7.5

7.5

10

31.79' (9.69 m)

2

10

15

15

31.85' (9.71 m)

68'

2

7.5

7.5

10

32.79' (10.00 m)

2

10

15

15

32.85' (10.01 m)

69'

2

7.5

7.5

10

32.79' (10.00 m)

2

10

15

15

32.85' (10.01 m)

72'

2

7.5

7.5

10

34.79' (10.61 m)

2

15

15

15

34.85' (10.62 m)

75'

2

10

10

10

35.79' (10.91 m)

2

15

15

15

35.85' (10.93 m)

78'

2

10

10

10

37.79' (11.52 m)

2

15

15

15

37.85' (11.54 m)

80'

2

10

10

10

38.79' (11.83 m)

2

15

15

15

38.85' (11.84 m)

81'

2

10

10

10

38.79' (11.83 m)

2

15

15

15

38.85' (11.84 m)

84'

2

10

10

15

40.79' (12.44 m)

2

15

15

15

40.85' (12.45 m)

87'

2

10

10

15

41.79' (12.74 m)

2

15

15

20

41.85' (12.76 m)

88'

2

10

10

15

42.79' (13.05 m)

2

15

15

20

42.85' (13.06 m)

90'

2

10

10

15

43.79' (13.35 m)

2

15

15

20

43.85' (13.37 m)

91'

2

10

10

15

43.79' (13.35 m)

2

15

15

20

43.85' (13.37 m)

92'

2

10

10

15

44.79' (13.66 m)

2

15

20

20

44.85' (13.67 m)

95'

2

10

15

15

45.79' (13.97 m)

2

15

20

20

45.85' (13.98 m)

98'

2

10

15

15

47.79' (14.57 m)

2

15

20

20

47.85' (14.58 m)

105'

3

15

15

20

50.79' (15.48 m)

3

20

20

20

50.85' (15.50 m)

113'

3

15

15

20

54.79' (16.70 m)

3

20

20

20

54.85' (16.72 m)

120'

3

15

15

20

58.79' (17.92 m)

3

20

20

20

58.85' (17.94 m)

WARNING

Electrical controls and wiring should be installed by a qualified electrician. The

motor disconnect switches and conductor cables should comply with the National

Electrical Code and any local codes. Locate reset and motor starting stations so

the operator can see that all personnel are clear of the equipment.