Introduction, Chapter 3 introduction, Product introduction – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-720-G2 User Manual

Page 15

PNEG-720-G2 12" and 16" Series II Sweep

15

3. Introduction

Product Introduction

Congratulations! Your selection of the GSI Series II Sweep is a wise investment. It will give you years of

dependable service. The main function of the Series II Sweep is to clean out the remaining grain, from

the bin, after all gravity unloading has finished. The GSI Series II Sweep is a single pass sweep only.

The unit will only operate in a round grain bin equipped with a center sump in the bin floor.

NOTE: The bin manufacturer should be contacted for their recommendations on your bin’s structural

integrity. The following are sweep criteria recommendations.

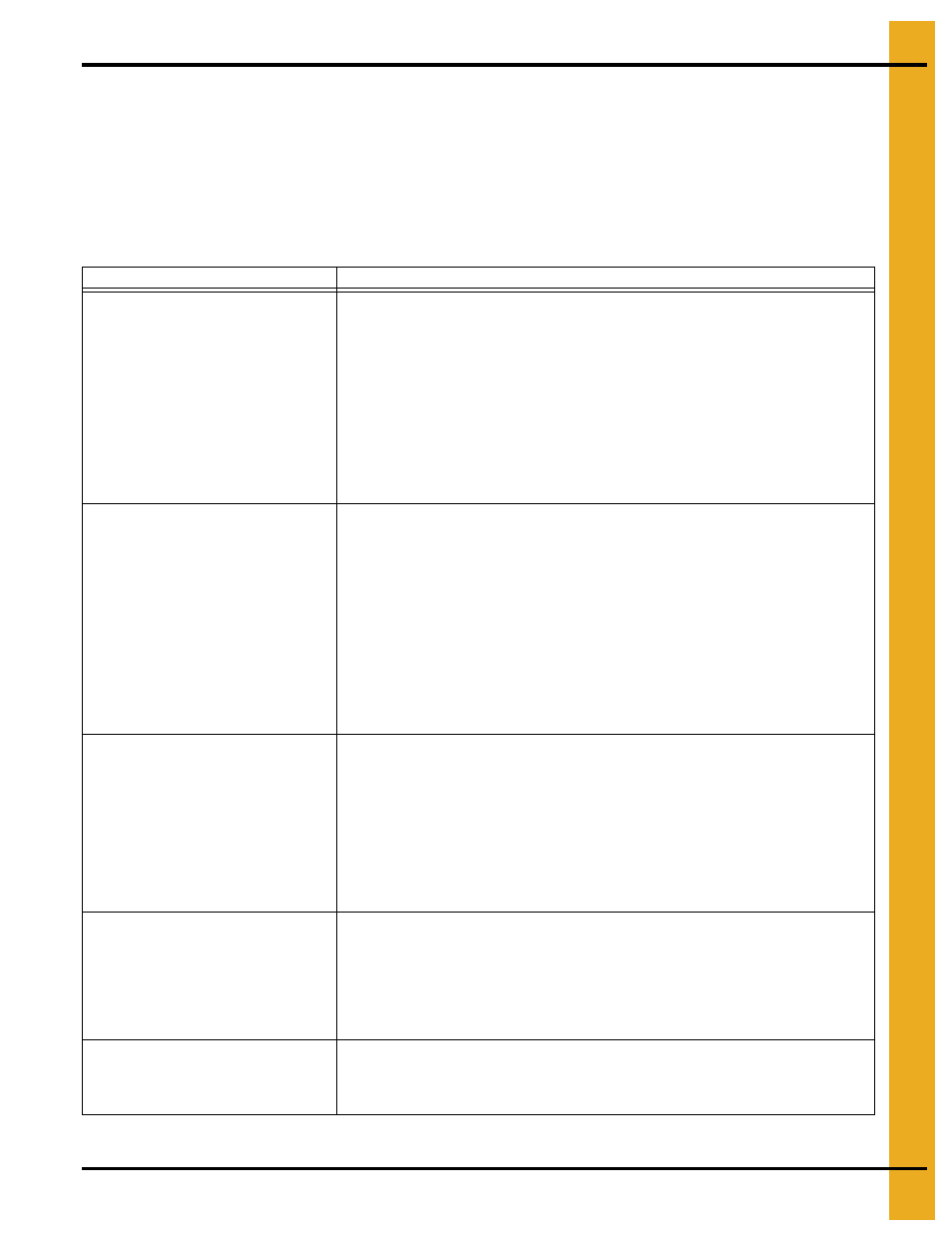

Issues

Recommendations

Flooring

A track is required under each of the sweep tires and jack wheels where they travel

over the aeration (steel) floor. This is the case for all steel flooring including full floor

and flush floor aeration. The track should be a minimum of 10 Ga. thick and made

from steel. The steel can be galvanized for the jack wheel paths but needs to have

a non-slip coating for the drive tire paths. The drive tire track coating must not be

course enough to damage the drive tires. A

is included that shows

radius dimensions locating the points of contact between the sweep and the bin floor.

The dimensions may be used to figure the material quantities of track to support the

sweep across the aeration flooring. The track material is not supplied with the sweep

and must be supplied by the installer or purchased from GSI. The dimensions

are approximate and the assembled sweep should be checked for exact points

of contact.

Center Sump Size

When installing a 12" standard sweep, the minimum recommended opening is

36" x 36". With a 16" standard sweep, it is 42" x 42". If installing a sump with collector

ring, the opening will be 42" x 42" for both sweep sizes.

The sump hopper supplied by GSI was designed with sufficient clearance around the

collector ring housing to allow grain to gravity flow through the hopper and be carried

away by the material handling equipment below. 42-3/4" is the maximum opening

size to allow rolling clearance for the casters assembled to the head end jack. If

made smaller, grain flow may be decreased to an unacceptable level.

**Flow of grain is limited to 15,000 BPH when using this sump and collector ring

housing assembly. The collector ring housing extends 22-1/2" down from the floor

surface and is approximately 14-1/4" x 14-1/4" in size.

Number of Intermediate Sumps

Intermediate sump pumps must be installed on a maximum of 10' centers where the

sweep will be parked during storage. The first intermediate sump should be placed at

a maximum of 10' from the center sumps and the end sump should be no more than

4' from the bin wall.

The extra sumps will help clean out the grain in front of the sweep, reducing the

start-up load. Doing this will save labor dollars and hours of work to dig out the

sweep and will help the sweep during start-up. The sweep is not designed to start-up

when submerged in material. The sweep should be parked behind the intermediate

sumps with sumps on the auger side of the sweep.

Routing the Power Supply to

the Sweep

There are three (3) options for routing the power. The most common option is to run

the cords out the door in the sidewall. Another option is to use the hopper sump with

collector ring. This allows the power to be transferred through a mechanical device in

the center sump and does not twist any cords. The third option is to use the pivot kit,

which routes the power cord through the center sump. Using this kit requires the

sweep to be backed up to the start point after sweeping. The pivot kit is not the

preferred choice due to the repeated cord twisting.

Floor Level Tolerance

The top edge of the sump hopper and the top edge of the “X” brace support must be

level with the floor. The floor must be level within 3/4" plus (or) minus, preferably less.

Any high or low points must be gradually sloped. The change in elevation should be

no more than 3/4" over 60".