Service guide for all portable dryers – Grain Systems PNEG-573 User Manual

Page 52

52

SERVICE GUIDE FOR ALL PORTABLE DRYERS

SERVICE GUIDE FOR ALL PORTABLE DRYERS

SERVICE GUIDE FOR ALL PORTABLE DRYERS

SERVICE GUIDE FOR ALL PORTABLE DRYERS

SERVICE GUIDE FOR ALL PORTABLE DRYERS

FAN PROPELLOR REMOVAL AND INSTALLATION

FAN PROPELLOR REMOVAL AND INSTALLATION

FAN PROPELLOR REMOVAL AND INSTALLATION

FAN PROPELLOR REMOVAL AND INSTALLATION

FAN PROPELLOR REMOVAL AND INSTALLATION

The fan propellor

fan propellor

fan propellor

fan propellor

fan propellor is secured to the

motor shaft

motor shaft

motor shaft

motor shaft

motor shaft by the use of a taper-

taper-

taper-

taper-

taper-

lock bushing, motor shaft key

lock bushing, motor shaft key

lock bushing, motor shaft key

lock bushing, motor shaft key

lock bushing, motor shaft key and

three cap screws

cap screws

cap screws

cap screws

cap screws.

CAUTION: Although the taper-lock

method of retaining the propellor

propellor

propellor

propellor

propellor

onto the motor shaft

motor shaft

motor shaft

motor shaft

motor shaft is simple, it is

essential that the following points be

read carefully and fully understood.

Improper installation can cause a

loose flying propellor

propellor

propellor

propellor

propellor, and result in

serious injury or death.

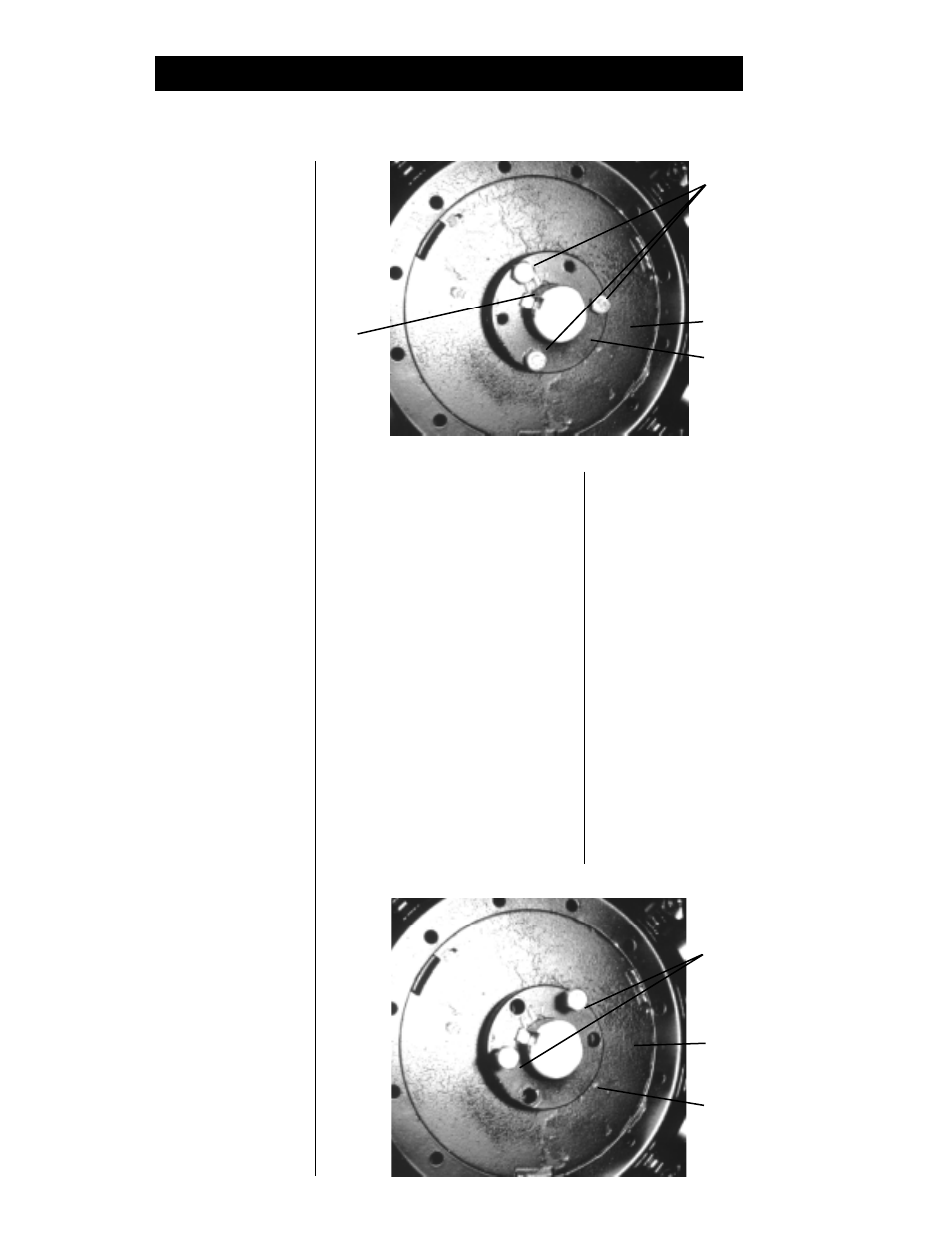

Capscrews installed

through threaded

holes of bushing

Fan Hub

Key

THREADED BUSHING

THREADED BUSHING

THREADED BUSHING

THREADED BUSHING

THREADED BUSHING

HOLES

HOLES

HOLES

HOLES

HOLES

The threaded holes within the bush-

bush-

bush-

bush-

bush-

ing

ing

ing

ing

ing are provided for disassembly

purposes only. Do not attempt to use

these holes for reassembly. They

will not allow the parts to lock onto

the shaft thereby causing a hazard-

ous operating condition.

Split Taper Bushing

Fan Hub

Fan blade

Fan blade

Fan blade

Fan blade

Fan blade

removal

removal

removal

removal

removal

When reassembling parts, the cap

cap

cap

cap

cap

screws

screws

screws

screws

screws must be installed through the

untapped clearance holes as shown.

This will cause the propellor

propellor

propellor

propellor

propellor to be

pulled forward onto the tapered bush-

tapered bush-

tapered bush-

tapered bush-

tapered bush-

ing

ing

ing

ing

ing, thus locking the parts securely

onto the motor shaft

motor shaft

motor shaft

motor shaft

motor shaft.

When fan servicing requires re-

moval and installation of the

propellor

propellor

propellor

propellor

propellor, make sure the propellor

propellor

propellor

propellor

propellor

is removed and reinstalled properly.

1. LOCK OUT the fan

fan

fan

fan

fan power sup-

ply, and REMOVE the fan

fan

fan

fan

fan

guard

guard

guard

guard

guard and the venturi

venturi

venturi

venturi

venturi, as re-

quired on some models.

CLEARANCE HOLES

CLEARANCE HOLES

CLEARANCE HOLES

CLEARANCE HOLES

CLEARANCE HOLES

Capscrews installed

through threaded

holes of bushing

Split Taper Bushing

Fan blade

Fan blade

Fan blade

Fan blade

Fan blade

installation

installation

installation

installation

installation

bushing

bushing

bushing

bushing

bushing and propellor

propellor

propellor

propellor

propellor. With the

propellor

propellor

propellor

propellor

propellor free from the bushing

bushing

bushing

bushing

bushing,

a wheel can be used to PULL the

bushing

bushing

bushing

bushing

bushing off the motor shaft

motor shaft

motor shaft

motor shaft

motor shaft.

REATTACH bushing

bushing

bushing

bushing

bushing onto pro-

pro-

pro-

pro-

pro-

pellor

pellor

pellor

pellor

pellor to prevent the loss of parts.

Note: During manufacture the

propellor and bushing are balanced

together and are marked with two

small dots to identify their original

alignment position. CHECK the

bushing

bushing

bushing

bushing

bushing and propellor

propellor

propellor

propellor

propellor to make

sure they have alignment marks.

MARK the alignment of the propellor

propellor

propellor

propellor

propellor

and bushing

bushing

bushing

bushing

bushing, if necessary.

2. REMOVE the three cap screws

cap screws

cap screws

cap screws

cap screws

from the clearance holes in the

taper-lock bushing

taper-lock bushing

taper-lock bushing

taper-lock bushing

taper-lock bushing.

3. INSTALL two grade 5 cap screws

cap screws

cap screws

cap screws

cap screws

into the threaded holes in bush-

bush-

bush-

bush-

bush-

ing

ing

ing

ing

ing. TURN caps

caps

caps

caps

caps by hand until

they bottom against the front sur-

face of the propellor

propellor

propellor

propellor

propellor.

4. BLOCK propellor

propellor

propellor

propellor

propellor to prevent it

from turning, and gradually TURN

the cap screws

cap screws

cap screws

cap screws

cap screws (up to 1/4 turn at

a time) until the propellor

propellor

propellor

propellor

propellor breaks

loose from the bushing

bushing

bushing

bushing

bushing and mo-

mo-

mo-

mo-

mo-

tor shaft

tor shaft

tor shaft

tor shaft

tor shaft. Carefully REMOVE