C-series dryer control panel – Grain Systems PNEG-573 User Manual

Page 14

14

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

C-SERIES DRYER CONTROL PANEL

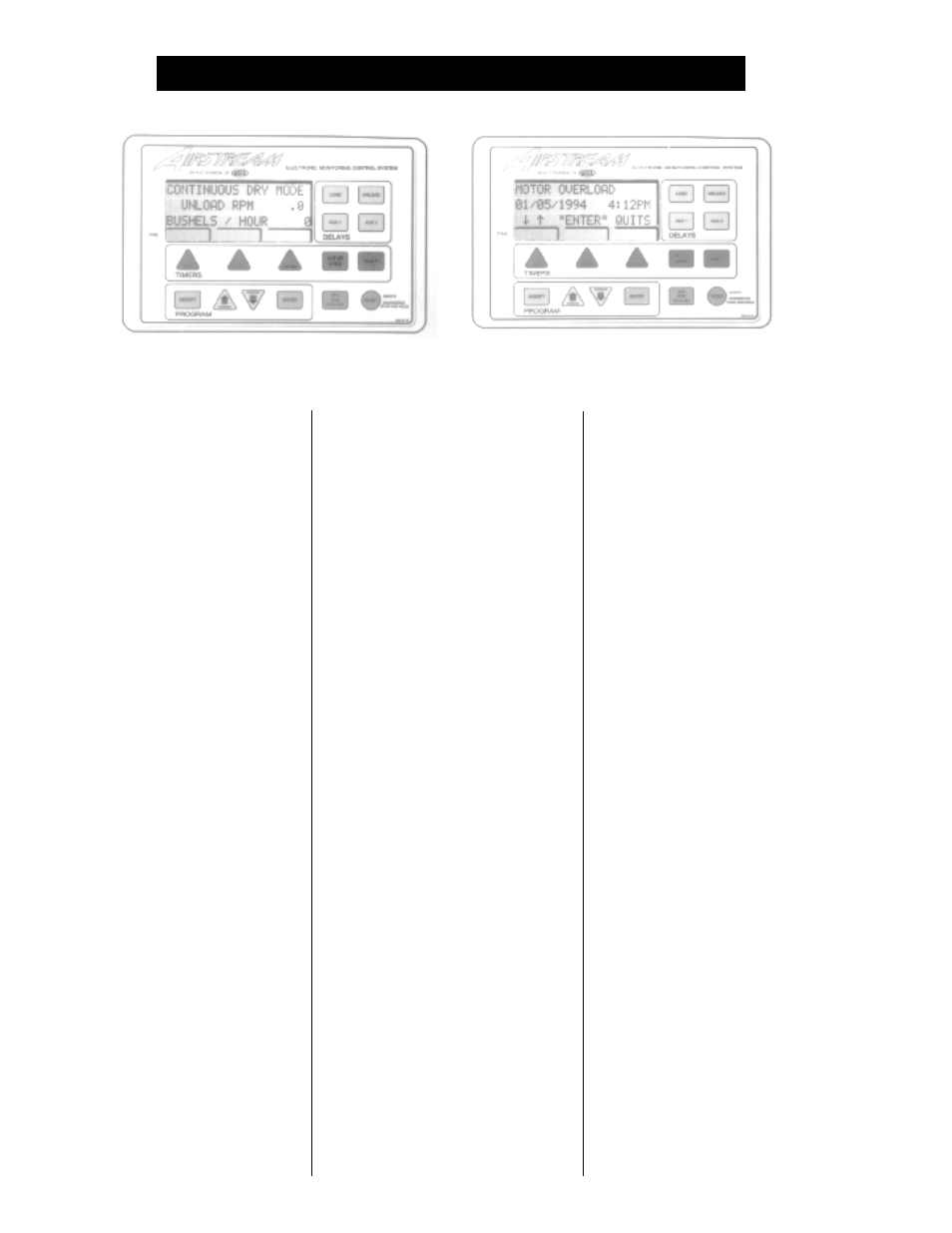

The Airstream Electronic Monitoring Control System showing several different LCD displays.

The Airstream Electronic Monitoring Control System showing several different LCD displays.

The Airstream Electronic Monitoring Control System showing several different LCD displays.

The Airstream Electronic Monitoring Control System showing several different LCD displays.

The Airstream Electronic Monitoring Control System showing several different LCD displays.

If the dryer runs out of grain while

the LOAD AUGER switch (fig. 1-7)

is in the AUTO position, the OUT OF

GRAIN timer (fig. 2-N) automatically

shuts OFF the dryer after the period

of time preset on the TIMER. When

pressed, the display will show the

amount of time left on the TIMER

and the percentage of time used by

the last load. A second screen will

appear with the TIMER'S setting,

and may be modified as described

in the BATCH TIMER section.

cedure as the TIMERS. The AUX 1

(fig.2-P) and AUX 2 (fig. 2-Q) DE-

LAYS are presently not being used.

SETTING THE OUT OF

SETTING THE OUT OF

SETTING THE OUT OF

SETTING THE OUT OF

SETTING THE OUT OF

GRAIN TIMER

GRAIN TIMER

GRAIN TIMER

GRAIN TIMER

GRAIN TIMER

TIMER is being used, and the sec-

ond line switches between TOTAL

BATCHES, UNLOAD RPM or TOTAL

BUSHELS. The third line indicates

TOTAL DRY TIME, and the fourth line

is TIME REMAINING on the TIMERS.

The Electronic Monitoring Control

Electronic Monitoring Control

Electronic Monitoring Control

Electronic Monitoring Control

Electronic Monitoring Control

System

System

System

System

System has four built in TIMER de-

lays. The LOAD DELAY (fig. 2-R) is

used to delay the starting of the load

load

load

load

load

auger

auger

auger

auger

auger when the dryer is unloading

to prevent the load auger

load auger

load auger

load auger

load auger from start-

ing and stopping. The UNLOAD

DELAY (fig. 2-S) is used to control

the amount of time the unload au-

unload au-

unload au-

unload au-

unload au-

ger

ger

ger

ger

ger runs after the metering rolls

metering rolls

metering rolls

metering rolls

metering rolls

stop to allow for auger

auger

auger

auger

auger cleanout.

Both the LOAD and UNLOAD DE-

LAYS are set using the same pro-

The Electronic Monitoring Control

Electronic Monitoring Control

Electronic Monitoring Control

Electronic Monitoring Control

Electronic Monitoring Control

System

System

System

System

System continuously checks all

safety circuits on the dryer, and will

automatically shut the dryer down

should a problem occur. The cause

of the dryer shutdown will be dis-

played on the LCD display (fig. 2-

A), and a beeper will sound on the

controller. To restart the dryer after

a safety shutdown, first correct the

reason for the shutdown, and then

press the DRYER POWER STOP

(FIG. 1-14) button to reset the circuit.

Press the START button (fig. 1-13).

The Electronic Monitoring

Electronic Monitoring

Electronic Monitoring

Electronic Monitoring

Electronic Monitoring

Control System

Control System

Control System

Control System

Control System stores in its

memory the time, date and cause for

the last 25 dryer safety shutdowns.

To review this information, hold the

RESET button in for five seconds.

The procedure for reviewing the

safety circuit shutdown log will be

displayed on the LCD display.

When the dryer is operating, the

LCD display (fig. 2-A) shows the

DRYER MODE OF OPERATION on

the first line, the BUSHELS PER

HOUR or the METERING ROLL

RPM on the second line and the

TOTAL BUSHELS DRIED on the

third line. By pressing the BPH/

RPM/TOTAL BU button (fig. 2-L) the

second line will alternate between

the METERING ROLL RPM's or the

BUSHEL PER HOUR rate that the

metering rolls

metering rolls

metering rolls

metering rolls

metering rolls are removing grain

from the dryer. The TOTAL BUSH-

ELS DRIED reading is the total since

the bushel counter was last reset.

To reset the BUSHEL COUNTER,

press and hold the RESET button

(fig. 2-M) for five seconds. Press the

ENTER button (fig. 2-J) through the

date and time settings, and follow

the instructions displayed on the

LCD for resetting the counter.

In the BATCH MODE, the first

line of the LCD display tells which

DRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUIT

DRYER SAFETY CIRCUIT

UTILIZING THE

UTILIZING THE

UTILIZING THE

UTILIZING THE

UTILIZING THE

BUSHEL COUNTER

BUSHEL COUNTER

BUSHEL COUNTER

BUSHEL COUNTER

BUSHEL COUNTER

SETTING THE LOAD AND

SETTING THE LOAD AND

SETTING THE LOAD AND

SETTING THE LOAD AND

SETTING THE LOAD AND

UNLOAD DELAYS

UNLOAD DELAYS

UNLOAD DELAYS

UNLOAD DELAYS

UNLOAD DELAYS