Fuel formula constants, Startup & operation for all portable dryers – Grain Systems PNEG-573 User Manual

Page 46

46

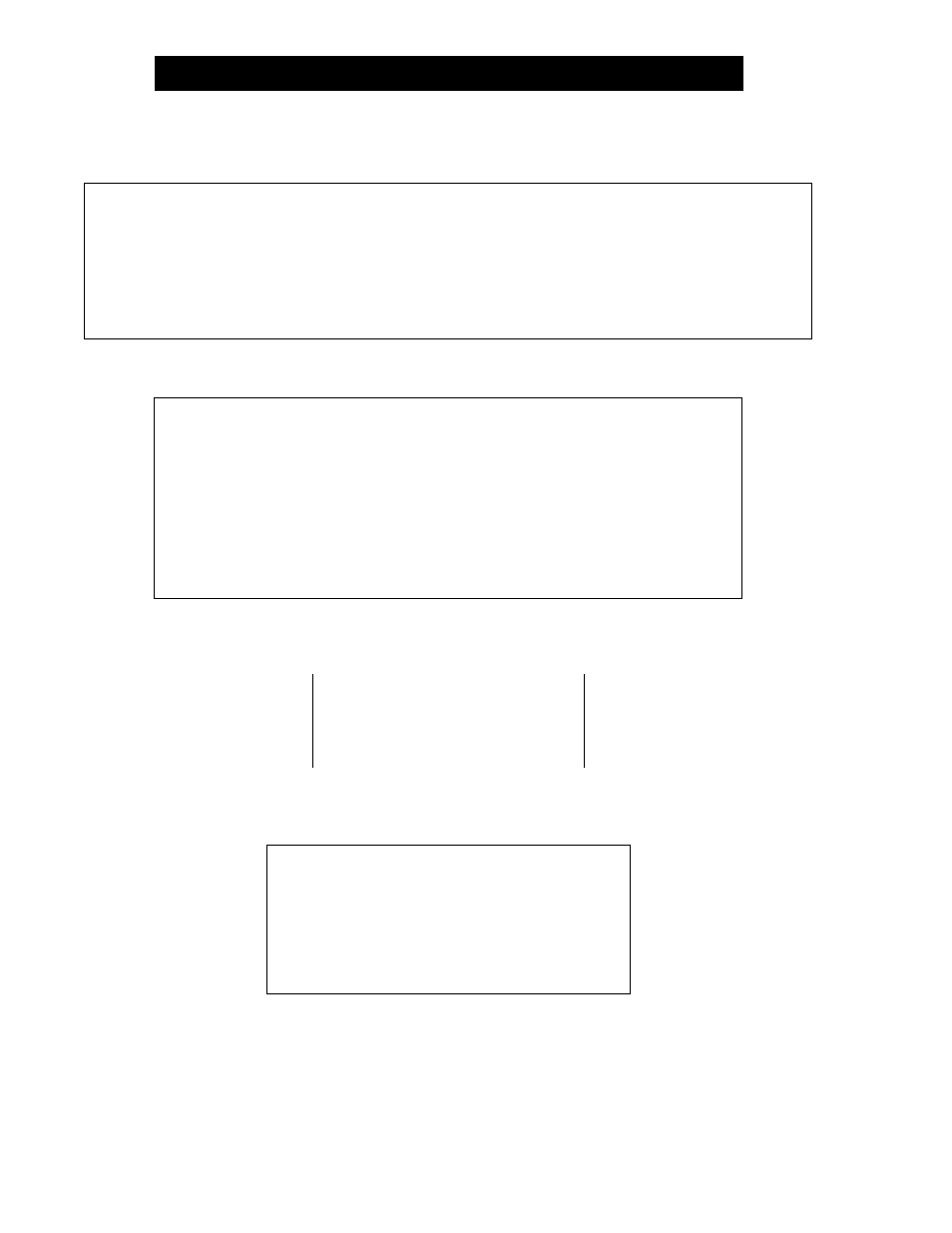

FUEL FORMULA CONSTANTS

FUEL FORMULA CONSTANTS

FUEL FORMULA CONSTANTS

FUEL FORMULA CONSTANTS

FUEL FORMULA CONSTANTS

GAS CALCULATION

GAS CALCULATION

GAS CALCULATION

GAS CALCULATION

GAS CALCULATION

1 gallon liquid propane

1 cubic foot natural gas

1 kw electricity

1,000 cubic feet of natural gas

1 therm of natural gas

1 gallon average $0.60

1 kilowatt average $0.05

1 therm average $4.90

= 91,500 BTU's

= 1,040 BTU's

= 3,413 BTU's

= 1 therm

= 1,040,000 BTU's

amps = total HP x 4.2

amps = total HP x 2.7

amps = total HP x 1.35

amps x volts = watts

watts/1,000 = kilowatts

For 230 volt single phase motors

For 230 volt three phase motors

For 460 volt three phase motors

Motors average 88% efficiency

ELECTRIC CALCULATION

ELECTRIC CALCULATION

ELECTRIC CALCULATION

ELECTRIC CALCULATION

ELECTRIC CALCULATION

OTHER INFORMATION

OTHER INFORMATION

OTHER INFORMATION

OTHER INFORMATION

OTHER INFORMATION

method of operation, grain density,

grain quality and outside conditions

will vary requirements.

1,044 btu are required to evaporate

one pound of free water at 100%

efficiency.

Approximately 1400 to 2000

BTU's are required to remove 1

pound of water from 25% moisture

corn when drying it down to 15%

moisture content. Type of dryer,

Dry & cool

6-7

Dry & cool with heat recovery

8-9

All heat

8-9

All heat with heat recovery

9-10

Top Dry cooling in bottom

9-11

APPROXIMATE BUSHELS PER GALLON OF FUEL AT 10 POINT REMOVAL

APPROXIMATE BUSHELS PER GALLON OF FUEL AT 10 POINT REMOVAL

APPROXIMATE BUSHELS PER GALLON OF FUEL AT 10 POINT REMOVAL

APPROXIMATE BUSHELS PER GALLON OF FUEL AT 10 POINT REMOVAL

APPROXIMATE BUSHELS PER GALLON OF FUEL AT 10 POINT REMOVAL

STARTUP & OPERATION FOR ALL PORTABLE DRYERS

STARTUP & OPERATION FOR ALL PORTABLE DRYERS

STARTUP & OPERATION FOR ALL PORTABLE DRYERS

STARTUP & OPERATION FOR ALL PORTABLE DRYERS

STARTUP & OPERATION FOR ALL PORTABLE DRYERS