Sensor too close to the vessel wall, Wrong orientation to the product, Foam generation – VEGA VEGAPULS 45 VBUS User Manual

Page 28

28

VEGAPULS 42, 44 and 45 – VBUS

Mounting and installation

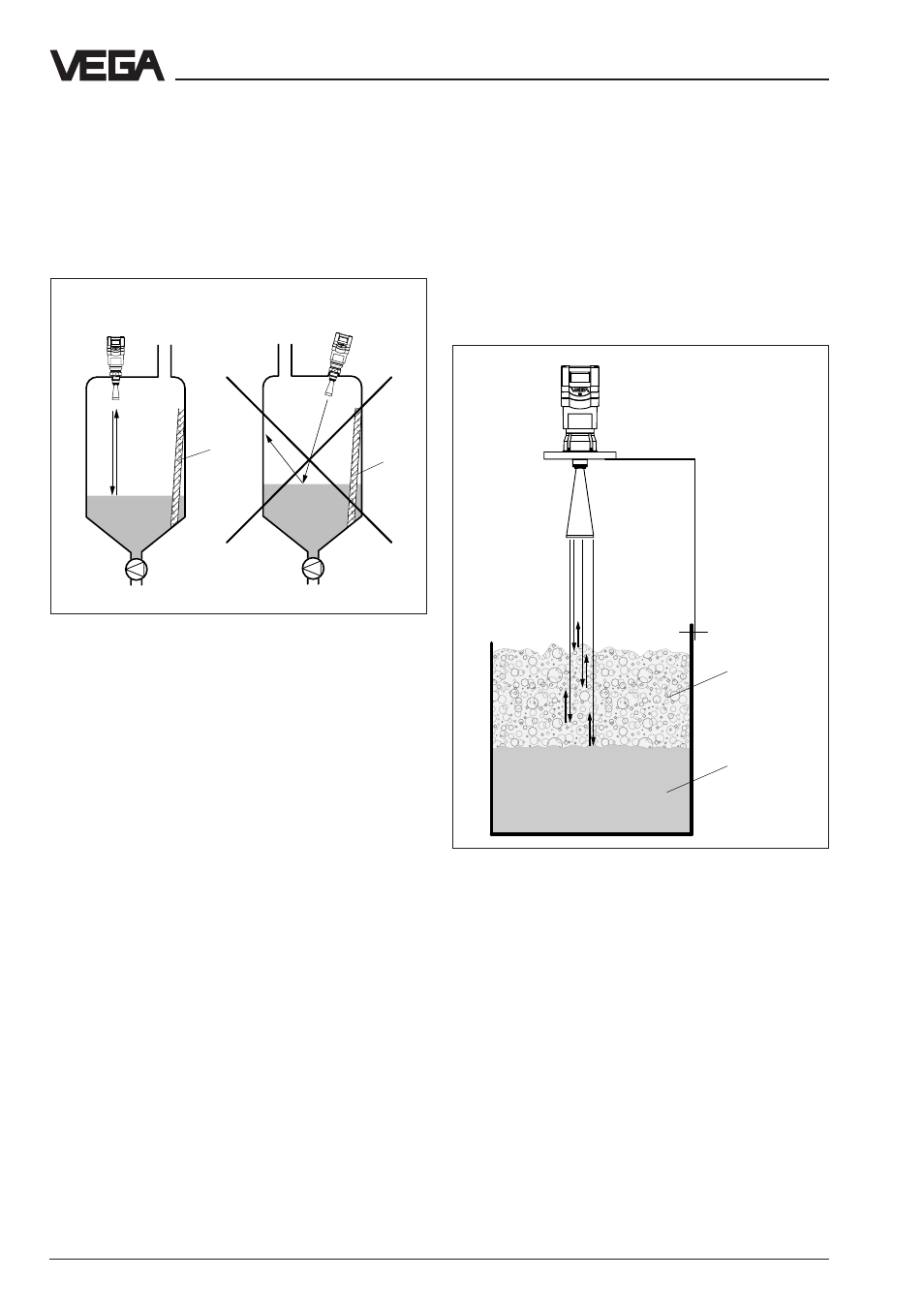

Sensor too close to the vessel wall

If the radar sensor is mounted too close to

the vessel wall, strong false echoes can be

caused. Buildup, rivets, screws or weld joints

superimpose their echoes onto the product

or useful echo. Please ensure sufficient dis-

tance from the sensor to the vessel wall.

In case of good reflection conditions (liquids

without vessel installations), we recommend

selecting the sensor distance so that there is

no vessel wall within the inner emission cone.

For products in less favourable reflection

environments, it is a good idea to also keep

the outer emission cone free of interfering

installations. Note chapter "3.1 General instal-

lation instructions".

Wrong orientation to the product

Weak measuring signals are caused if the

sensor is not directly pointed at the product

surface. Orient the sensor axis perpendicu-

larly to the product surface to achieve reliable

measuring results.

Foam generation

Conductive foam is penetrated by the radar

signals to different depths and generates a

number of single (bubble) echoes. The sig-

nals in the foam are also damped, like heat

radiation that tries to penetrate styrofoam.

Thick, dense, creamy foam, and especially

conductive foam, on the product surface can

cause incorrect measurements.

Foam generation

conductive

foam

Liquid

Direct sensor vertically to the product surface

Correct

Wrong

Ladder

Ladder

Take measures to avoid foam, measure in a

bypass tube or use a different measuring

technology, e.g. capacitive electrodes or

hydrostatic pressure transmitters.

In many cases, VEGAPULS 54 radar sensors

with 5.8 GHz operating frequency achieve

considerably better and more reliable meas-

uring results in foam applications than type

40 sensors with 26 GHz technology.