Installation guide, Troubleshooting – Veris Industries H8036 SERIES Install User Manual

Page 10

Z201686-0N

PAGE 10

©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

08122

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

H8035/H8036

INSTALLATION GUIDE

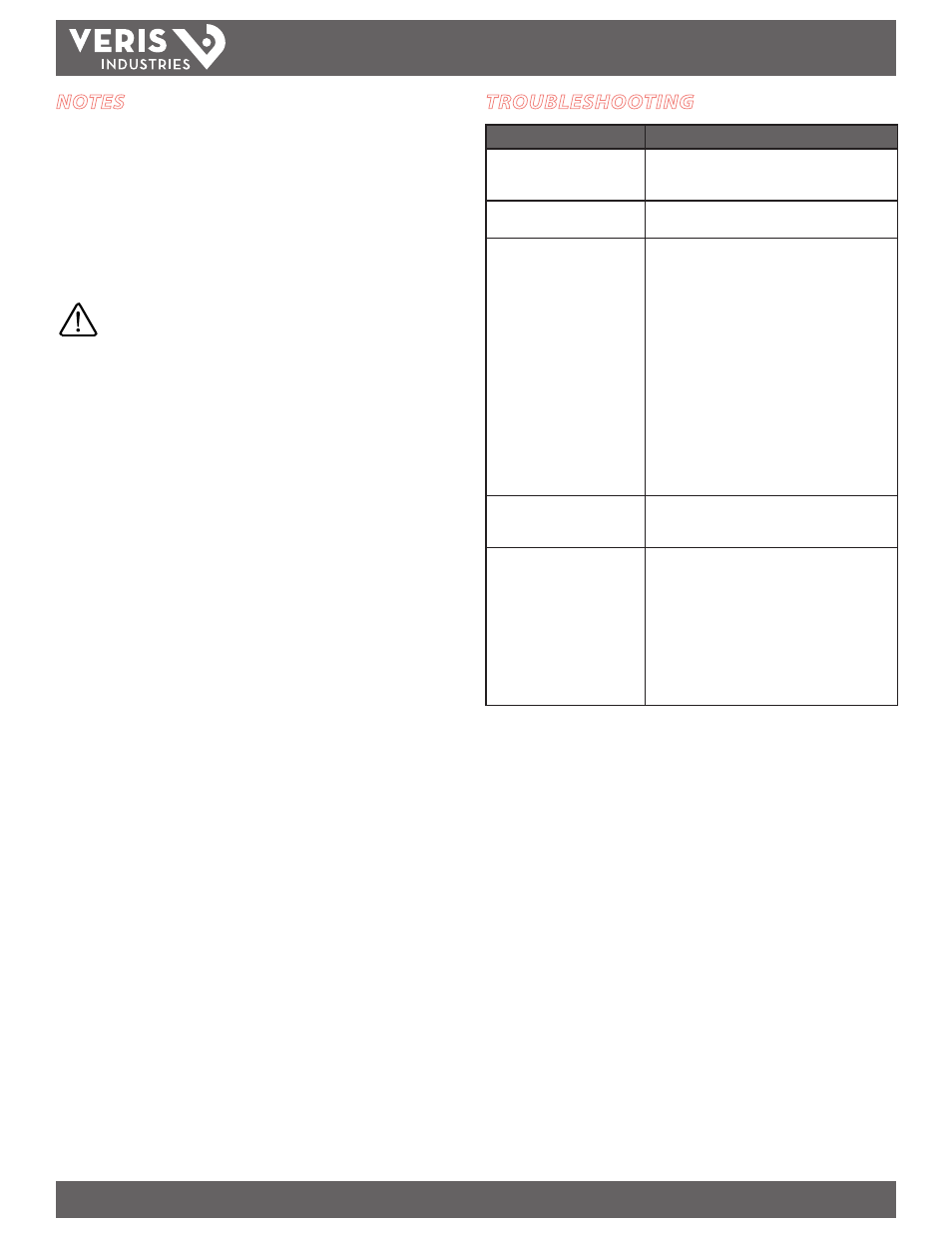

TROUBLESHOOTING

Problem

Solution

Status LED does not blink

Check fuses and voltage connections. Status LED should

blink regardless of CTs, Modbus connections, and DIP

switch setting.

Enercept interferes with another

device on the Modbus network

Set DIP switches to a different Modbus address not in

use.

Readings seem highly inaccurate. • Check that each CT is installed on the conductor with

the corresponding color voltage input lead attached. In

most cases, incorrect wiring will cause the Status LED

to blink red (slowly). However, a power factor lower

than 0.5 could cause the LED to blink this way, even if

the unit is installed properly.

• It does not matter which side of the CT faces towards

the load.

• If current is below 7% of full scale maximum for the

CT, use a smaller CT or wrap each wire through the CT

multiple times

• Check current with an amp-clamp.

Expected power:

kW = Volts x Amps x 1.732 x PF / 1000

kW = Horsepower x 0.746

PF is usually 0.7 to 0.95, depending on the load.

Enercept goes offline when load is

switched off.

Connect voltage leads on the Line side of the conductor.

The Enercept cannot communicate on the Modbus

network without voltage.

Status LED blinks red.

• If the LED blinks quickly (i.e., about 5 blinks in two

seconds), then use a CT with a higher amp rating.

• If the LED blinks slowly (i.e., about 1 blink per

second), then the CTs are not installed on the correct

conductors or the power factor is less than 0.5. The

Enercept can accurately measure these low PFs, but

few loads operate normally at such a low power factor.

• If the LED blinks slowly (i.e., about 1 blink per

second), the monitored load might be less than 10%

of the CT maximum ratings.

NOTES

1. DO NOT GROUND THE SHIELD INSIDE THE ELECTRICAL PANEL. Insulate all Modbus

wires, including the shield, to prevent accidental contact with high voltage

conductors.

2. Mechanically secure the Modbus cable where it enters the electrical panel.

3. Connect all Modbus devices in a daisy-chain fashion. Use a 120 Ω terminating

resistor between (+) and (-) on the first and last devices in the chain.

4. Use shielded twisted pair wire BELDEN 1120A or similar for the Modbus cable.

WARNING: After wiring, remove all scraps of wire or foil

shield from the electrical panel. This could be DANGER-

OUS if wire scraps come into contact with high voltage

wires!