Ohaus EXPLORER PRECISION HIGH CAPACITY BALANCES Manual User Manual

Page 94

EN-92

EXPLORER BALANCES

5.3.4

AutoCal

™ Adjustment

Use this calibration method to adjust the zero calibration point, without affecting the span or linearity

calibration.

Calibration Adjust may be used to adjust the result of the Internal calibration by +100 divisions.

Note: Before making a calibration adjustment, perform an Internal Calibration. To verify whether an

adjustment is needed, place a test mass equal to the span calibration value* on the pan and note the

difference (in divisions) between the nominal mass value and the actual Balance reading. If the difference

is within +1 division, calibration adjustment is not required. If the difference exceeds +1 division,

calibration adjustment is recommended. (*See Table 5-1, below.)

Example:

Actual weight reading:

200.014

Expected weight reading:

200.000 (Test mass value)

Difference Weight (d):

0.014

Difference weight in digits:

–14 (Adjust value)

To perform a Calibration Adjustment, touch AutoCal Adjustment from the Calibration Menu; Enter the

value (positive or negative divisions) to match the difference noted earlier in the procedure and press .

Recalibrate using Internal Calibration. After calibration, place the test mass on the pan and verify that the

mass value now matches the displayed value. If not, repeat the procedure until Internal Calibration

reading agrees with the test mass.

Once completed, the balance stores the Adjustment value and the display returns to the current

application.

5.3.5

Span Calibration

Span calibration uses two calibration points, one at zero load and the other at specified full load (span).

Refer to Table 5.1 for Span values. For detailed calibration mass information please see the specification

tables in section 9.

Note: Factory default settings are shown in bold.

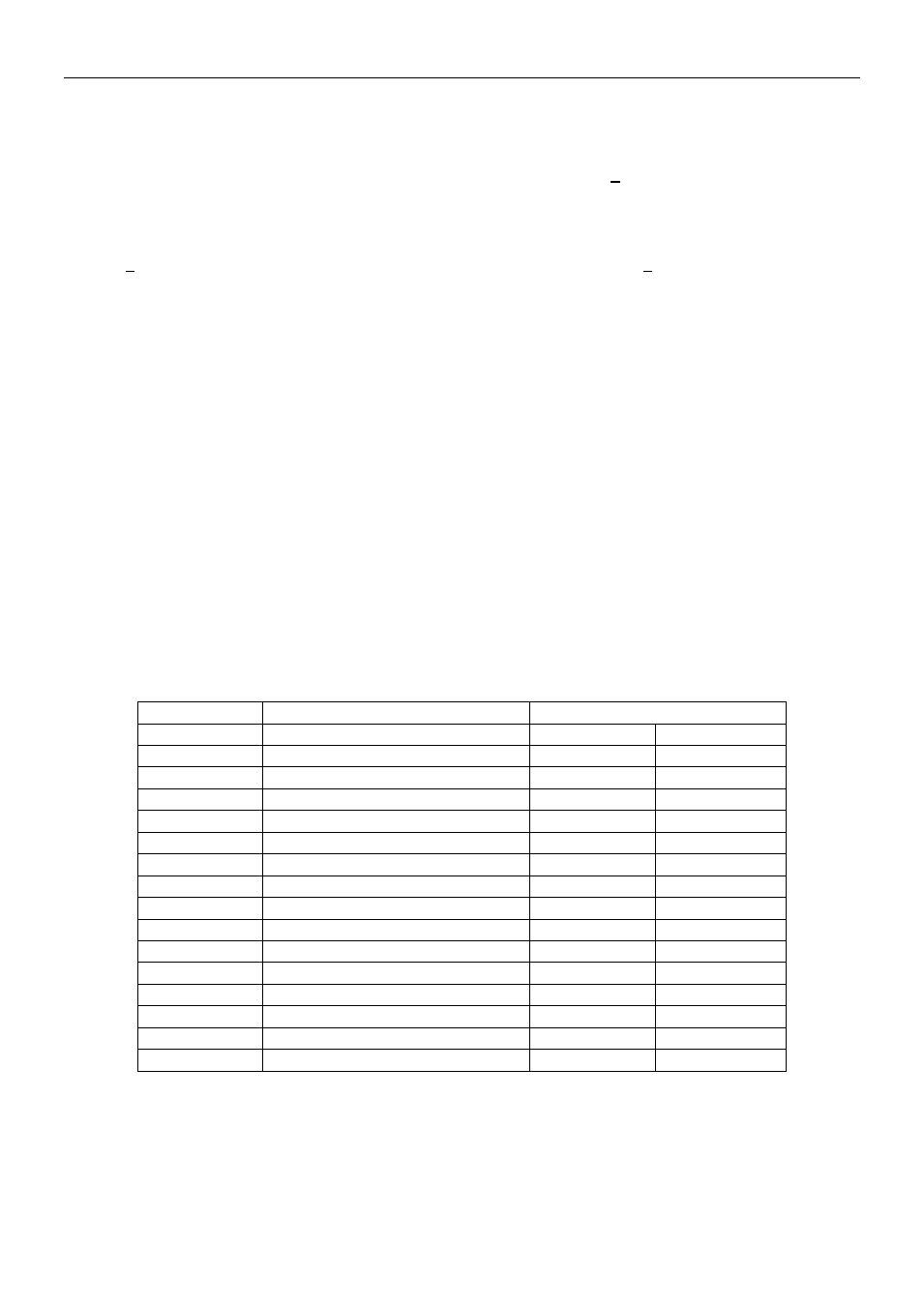

TABLE 5-1 Calibration Masses

Model

Span Calibration Points

Weight Class

EX124

50g, 100g

ASTM Class 1

OIML E2

EX224

100g, 150g, 200g

ASTM Class 1

OIML E2

EX324, M, N

150g, 200g, 300g

ASTM Class 1

OIML E2

EX223

100g, 150g, 200g

ASTM Class 1

OIML E2

EX423

200g, 300g, 400g

ASTM Class 1

OIML E2

EX623

300g, 400g, 500g, 600g

ASTM Class 1

OIML E2

EX1103, M, N

500g, 1000g

ASTM Class 1

OIML E2

EX2202

1000g, 2000g

ASTM Class 1

OIML E2

EX4202

2000g, 3000g, 4000g

ASTM Class 1

OIML E2

EX6202

3000g, 4000g, 5000g, 6000g

ASTM Class 1

OIML E2

EX10202, M, N

5000g, 10,000g

ASTM Class 1

OIML E2

EX6201

3000g, 4000g, 5000g, 6000g

ASTM Class 2

OIML F1

EX10201

5000g, 10,000g

ASTM Class 1

OIML E2

EX12001

3000g,5000g,10000g, 12000g

ASTM Class 2

OIML F1

EX24001

10000g,15000g,20000g, 24000g

ASTM Class 1

OIML F1

EX35001

10000g,20000g,30000g, 35000g

ASTM Class 1

OIML F1

With the balance turned ON and no load on the pan, touch Span Calibration to initiate the procedure.

Additional calibration values to be used are shown on the display. The best accuracy is achieved using

the mass closest to the full span value.

Note: To change the span calibration point, touch the alternate weight shown on the display.

Follow the screen instructions and place the specified calibration weight on the scale when prompted to

do so. When complete, the display shows the Span calibration status and returns to the current

application.