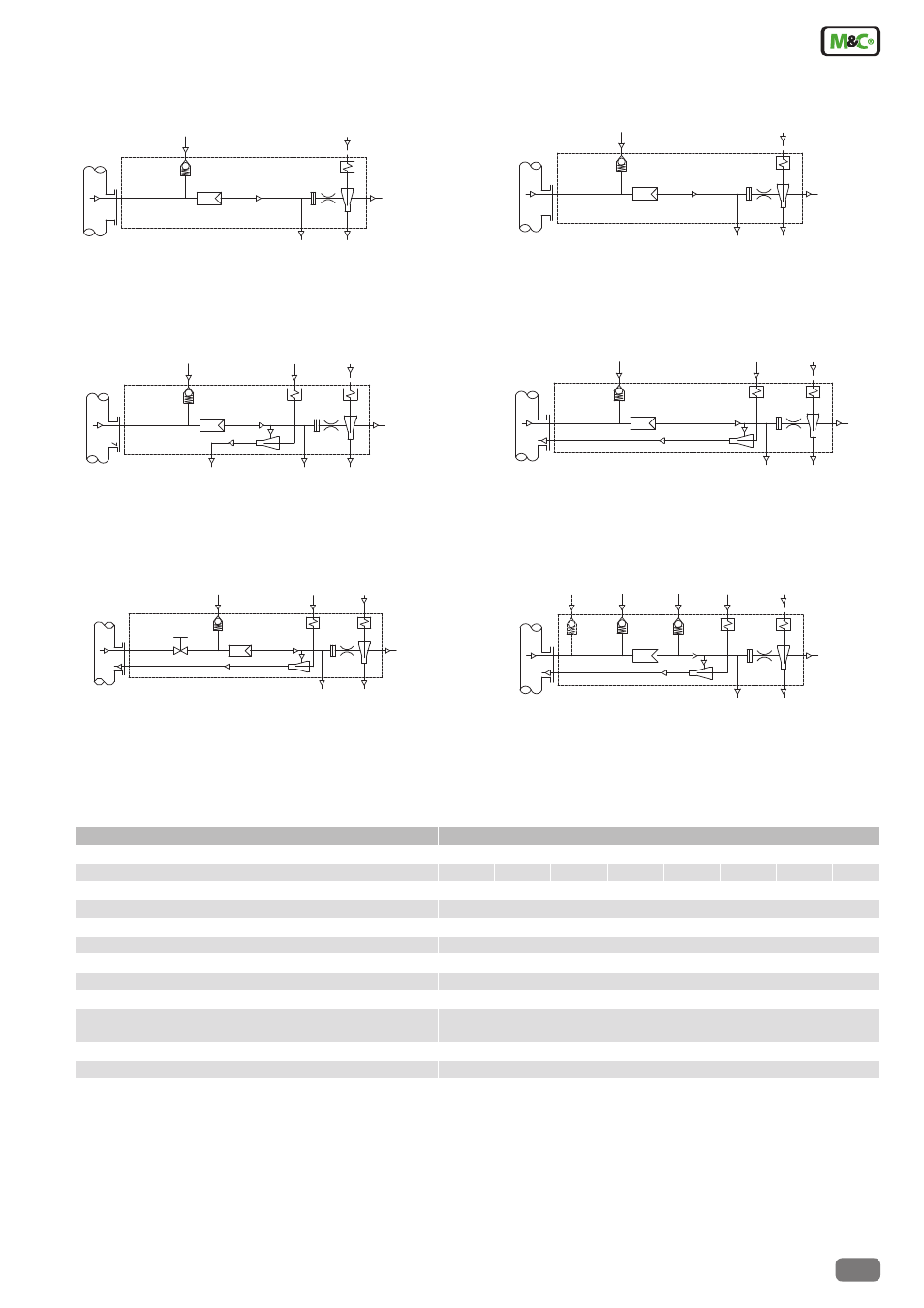

Sp2006-h/dil-br-va, Function diagrams, Sp2006-h/dil-b – M&C TechGroup SP2006-H280_DIL Data sheet User Manual

Page 3

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

[email protected] • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

5.2

Technical specifications and illustrations are without

obligation, subject to modifications. 04.06/04.08

*Standard, others to be indicated along with order, intermediate values possible.

1)

approx. at 3 bar dilution gas behind pressure controller.

2)

-5% not possible for orifice „g“.

3)

with injector version I. Further technical data see leaflet SP2000, 2-1.1a.

Technical Data

SP2006-H/DIL

SP2006-H280/DIL

SP2006-H/DIL-BR

SP2006-H/DIL-BR-BBF (-BB)

not diluted

Sample out

Sample out

diluted

180°C

Cal. gas

Vacuum gauge

Dilution gas

not diluted

Sample out

Sample out

diluted

280°C

Cal. gas

Vacuum gauge

Dilution gas

not diluted

Sample out

Sample back to process

Sample out

diluted

180°C

Cal. gas

gauge

Dilution gas

Bypass -BR

Vacuum

Sample back to process

Sample out

not diluted

Sample out

diluted

180°C

Blow back

Option:BB

Cal. gas

Option:BB-F

Blow back

Bypass -BR

Vacuum gauge

Dilution gas

SP2006-H/DIL-BR-VA

Bypass -BR

not diluted

Sample out

Sample gas back to process

Cal. gas

180°C

diluted

Sample out

Dilution gas

Vacuum

gauge

/VA

Function Diagrams

Series SP

®

Version gas sample dilution probe SP2006-H/DIL ...

Insitu sample tubes and pre filters optional on request

see leaflet 2-1.1a; 2-1.5.1; 2-1.6.1; 2-1.9.5

Dilution rates with the critical orifices ”a“ - ”g“

3)

a = 500

b = 200

c = 100

d = 50

e = 30*

f = 20

g = 10

: 1

Sample flow rate depending on the critical orifices ”a“ - ”g“

a = 1,4

b = 2,7

c = 5,5

d = 11

e = 19*

f = 28

g = 55

l/hr

1)

Possibility to adapt the dillution factor

with dillution gas pressure-adjustment -5% to +30%

2)

Dillution gas flow rate with injector version I or II

I: 480 - 600Nl/hr, optional for higher dilution rates II: 1800-3000 Nl/hr

Dilution gas pressure on inlet of pressure controller

min. 4,5 bar g, max. 16 bar g

Bypass injector /B: gas pressure - gas flow rate - sample gas flow rate

at approx. 2 bar g - injector gas approx. 300 l/hr - sample gas approx. 150 l/hr

Process pressure

0,9 up to 2 bar abs.

Fault caused by process temperature variations

operation independent from process temperature

Fault caused by process under- or overpressure

no fault as long as the differential pressure ∆P at the dilution unit is

>0,5 bar g and test gas is given to the probe under process conditions

Fault caused by atmospheric pressure variations

<1% with a variation of 50 mbar

Materials in contact with the sample gas

stainless steel 316Ti, quartz glass, FPM, graphite

Weight

approx. 30 kg

SP2006-H/DIL-B

Sample out

not diluted

Sample out

diluted

180°C

Cal. gas

Bypass -B

Vacuum gauge

Dilution gas

Bypass out