Technical data – M&C TechGroup SP2400-H Data sheet User Manual

Page 2

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

[email protected] • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

2.1

Technical Data

Technical specifications and illustrations are without

obligation, subject to modifications. 10.04/06.06

Gas Sample Probe Version

SP2000

SP2000-H

SP2300-H

SP2400-H

Part No.

20S1000

20S2000

20S3000

20S3500

Protective cover

no

yes

yes

yes

Degree of protection

IP54 EN60529

Filter housing material

Stainless steeel 316*

PTFE

Titanium

Sealing materials

FPM* /7aT** = PTFE /H320** = graphite

Probe flange sealing material

Novapress

Insitu probe tube/prefilter

Optional

Sample pressure max.

0,4-6 bar* abs., /7aT**= 2 bar abs., /HP** = 25 bar abs.

0,4-2 bar abs.

0,4-6 bar abs.

Ambient temperature

20 °C to +180 °C

-20 °C to +60 °C*** /PT100, /Fe-CuNi, /Ni-CrNi** = -20°C to +80°C

Filter chamber volume

120 cm3

Filter element, porosity

S-2K150= Ceramic*, 2micron, /F-0, 1GF150= Glass fibre**, 0,1 micron, /FW= Spun glass**

Thermostat, Temperature adjustment

0-180°C* /H320**= 0-320°C /PT100** /Fe-CuNi** /Ni-CrNi**

Ready for operation

after 40min /H320** = after 60min

Low temperature alarm contact*

Contact rating: 250V, 3A~, 0,25A= Alarm point: ∆T 30°C

Sample gas outlet connection

1x 1/4“ NPTi* tube connectors ø 6, 8 or 10 mm** /H320**= 6 mm

Backflush/Test gas connection

1/4“ NPTi* /R**, /H320**= tube ø 6 mm

Power supply

230V 50/60 Hz, 800W /115V** = 115V 60Hz, 800W (fuse protection 10A)

Electrical connections

Terminals max. 4mm2, 2x PG 13,5 cable gland

Electrical equipment standard

EN 61010, EN 60519-1

Mounting flange

DN65 PN6-B

>DN or ANSI possible** /HP** = DN50 PN25

Mounting flange material

SS316Ti

PTFE

Titanium

Weight

7 kg*

15,4 kg*

15,4 kg*

14,5kg*

*

Standard

**

Options (/H320 not for SP2300-H, /7aT** not for SP2300-H and SP2400-H)

*** In case of higher ambient temperatures use option PT100 (Part No. 20S9025) or thermocouple Fe-CuNi respectively Ni-CrNi (Part No. 20S9027 resp. 20S9028) instead of the thermo-

state controller. Then, an additional electronic temperature controller (see data sheet 2-5.1) is necessary.

∆P and T90 at flow of:

100

200

500

1000

1500

3000 (only /HF)

Nl/hr

∆P with new filter element S-2K150/GF150

0,007

0,011

0,02

0,058

0,135

0,240/0,225

bar

T90-time for SP2000-H without tube

6

3,5

1

<0,5

<0,5

<0,5

s

Differential pressure and T90-time

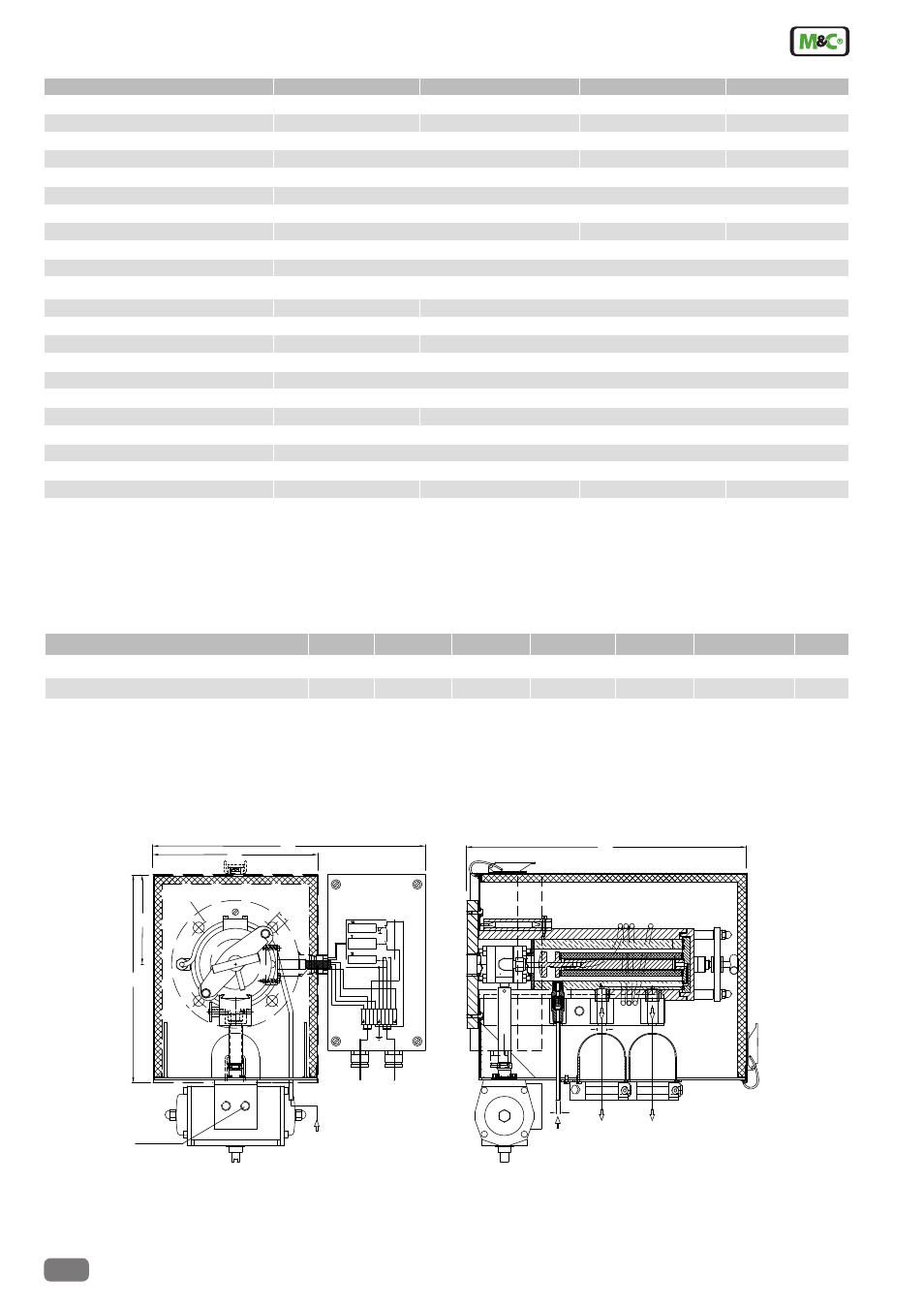

Dimensions

SP2000-H basic version with options (Examples)

Dimensions in mm

260

(115V,60Hz)

230V,50Hz

2

N

1

L 'L

5

3 4

6 8

7

9

207

340

110

T >+30°C

0-180°C

T <-30°C

345

G 1/4" i

Actuator

pressure inlet

(test gas)

Blow back

Alarm contact

Power

Tset

(Blow back)

Test gas

Sample gas

outlet *

Second sample

gas outlet

o

u

130

14

6

1/4"NPTi

*Standard